Liposomes

- 1. 1 LIPOSOMES Dr. Anil Pethe Shobhaben Pratapbhai Patel School of Pharmacy & Technology Management, SVKM’S NMIMS, Mumbai

- 2. Introduction Advantages & Disadvantages Classification Manufacturing of liposomes Liposome characterization and control Stability consideration for liposomal formulations Regulatory science of liposome drug products Drug release from liposomes Applications Recent innovations Approved liposome products Contents

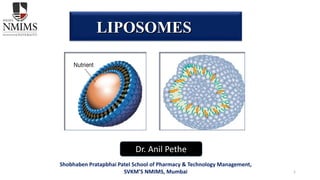

- 3. • The word liposome derives from two Greek words: lipo ("fat") and soma ("body"); it is so named because its composition is primarily of phospholipid. • The preparation of liposomes, with entrapped solutes, was demonstrated for the first time in 1965 by Prof. A.D. Bangham of the Cambridge University (UK). • They were discovered when Bangham and R. W. Horne were testing the institute's new electron microscope by adding negative stain to dry phospholipids. Introduction

- 4. • Liposomes are microscopic spheres made from fatty materials, predominantly phospholipids. • Made up of one or more concentric lipid bilayers, and range in size from 50 nanometers to several micrometers in diameter Definition

- 5. Suitable for delivery of hydrophobic, hydrophilic and amphipatic drugs & agents Chemically and physically well characterized entities Biocompatible Suitable for controlled release Suitable to give localized action in particular tissues. Suitable to administer via various routes Advantages

- 6. Disadvantages Less stability. Batch to batch variation. Difficult in large scale manufacturing and sterilization. High production cost. Once administered, liposomes can not be removed. Some times phospholipids undergoes hydrolysis and oxidation reactions Leakage and fusion. Allergic reaction may occur with liposomal constituents.

- 7. Classification based on size of liposomes Classification based on method of preparation Classification based on composition and in vivo application Classification

- 8. Small unilamellar vesicles Medium sized unilamellar vesicles Large unilamellar vesicles Giant unilamellar vesicles Unilamellar vesicles Oligolamellar vesicles Multilamellar large vesicles Multivesicular vesicles Classification based on size

- 9. Vesicles prepared by extrusion method. Vesicles prepared by French press. Vesicles prepared by fusion. Vesicles prepared by reverse phase evaporation. Frozen and thawed MLV. Dehydration and rehydration vesicles. Stable plurilamellar vesicles. Classification based on method of preparation

- 10. Classification based on its application Conventional Liposomes

- 11. • Inhibition of the rapid uptake of liposomes by the reticulo-endothelial system (RES) and reduction of the rate of drug leakage have resulted in long- circulating liposomal drug systems with valuable pharmacologic properties. • Particularly, the coating of liposomes with polyethylene-glycol (PEG) confers optimal protection to the vesicles from RES-mediated clearance, while bilayer rigidification using high Tm phospholipids reduces the rate of leakage of liposome contents. • These carrier systems display an improved extravasation profile with enhanced localization in tumors and possibly in other tissues, such as skin. Long circulating liposomes (Stealth Technology)

- 12. • An anti-cancer drug, doxorubicin, encapsulated in small-sized (< 100nm diameter), PEG-coated liposomes with a rigid bilayer shows a unique pharmacokinetic pattern, characterized by extremely long half-life, slow clearance, and small volume of distribution. • Liposome longevity in circulation correlates positively with high drug levels in the extracellular tumor fluid and with enhanced therapeutic efficacy in a variety of tumor models regardless of the site of tumor growth. Long circulating liposomes (Stealth Technology) cont.

- 13. • Target specific ligands, such as antibodies, immunoglobulins, lectins and oligosaccharides attached to the surface Targeted liposomes

- 14. • Cationic liposomes are prepared from at least one cationic phospholipid. The positively charged lipid bilayers can form complexes with negatively charged nucleic acid by simple mixing. • The resulting cationic liposomes-nucleic acid complexes, called lipoplexes, are formed by a combination of electrostatic attraction and hydrophobic interaction and have been extensively used as nonviral vectors for the intracellular delivery of therapeutic genes. • The nonviral vectors based on nanoparticles (50–500 nm) were already tested to transport plasmid DNA. Cationic liposomes

- 15. Temperature sensitive liposome The temperature-sensitivity of such liposomes allows the release of compounds entrapped within the interior aqueous space of the liposome, and/or the release of compounds associated with the lipid bilayer, at a target site that is either heated (as in the clinical procedure of hyperthermia) or that is at an intrinsically higher temperature than the rest of the body (as in inflammation). Traditional temperature-sensitive liposomes require relatively high temperatures (42–45°C) to induce drug release. Temperatures in this range are not readily achievable throughout a tumor volume in the clinic because of patient pain during heating and potential for normal tissue injury .In contrast, low temperature-sensitive liposomes release their contents at 39–42°C.

- 16. pH sensitive liposome These liposomes are stable at physiological pH (pH 7.4) but undergo destabilization and acquire fusogenic properties under acidic conditions, thus leading to the release of their aqueous contents. The theory of pH-sensitive liposomes emerged from the reality that certain enveloped viruses developed strategies to benefit from the acidification of the endosomal lumen to infect cells, as well as from the observation that some pathological tissues (tumours, inflamed and infected areas) exhibit an acidic environment as compared with normal tissues .

- 17. pH sensitive liposome (cont.) Different classes of pH-sensitive liposomes have been proposed in the literature, based on the mechanism of triggering pH sensitivity. The most commonly established hypothesis involves the blend of phosphatidylethanolamine (PE) or its derivatives with compounds containing an acidic group (e.g. carboxylic group) that acts as a stabilizer at neutral pH. Contemporary studies describe the use of novel pH-sensitive lipids, synthetic fusogenic peptides/ proteins either encapsulated or included in the lipid bilayer and attachment of pH-sensitive polymers with liposomes.

- 19. • Phospholipids • Synthetic Phospholipids • Glycerolipids • Sphingolipids • Glycosphingolipids • Cholesterol • Polymeric material • Charge-inducing lipids Materials used in preparation of liposomes

- 21. Phase transition temperature Stability Charge Lipid mixtures Cholesterol Source Factors to be consider while selecting lipids

- 22. The Phase transition temperature (Tc) of phospholipids is a temperature at which phospholipids transit from gel to liquid crystalline state. Factors affecting Tc. The nature of the polar head group. phosphatidylcholine (PC) and phosphatidylglycerol (PG) with the same hydrocarbon chains have similar Tc, but the corresponding phosphatidylethanolamine (PE), has a higher Tc. For example, the Tc of Dipalmitoyl phosphatidylcholine (DPPC) and Dipalmitoyl phosphatidylglycerol (DPPG) are both 41 C, whereas Dimyristoyl phosphatidylethanolamine (DPPE) is 63 C, which is attributed to a stronger head group interaction. The length of the hydrocarbon chains. Phospholipids with longer hydrocarbon chains have a higher Tc than those with shorter ones. For example, the Tc of Distearoyl phosphatidylcholine (DSPC) is 55 C, and yet Dipalmitoyl phosphatidylcholine (DPPC) is 41 C. Phase transition temperature (Tc)

- 23. Factors affecting Tc. The degree of saturation of the hydrocarbon chains. For phospholipids with the same head group and length of aliphatic chain, high saturation in the hydrocarbon chains increases the Tc. For example, the Tc of DSPC is 55 C, whereas Dioleoyl phosphatidylcholine (DOPC) is 20 C. Purity. The low purity of phospholipids widen the range of Tc. Naturally occurring phospholipids are usually mixtures of components having different length hydrocarbon chains.

- 24. Stability In order to make the drugs escape from being degraded into inactive compounds by enzymes in lysosomes after endocytosis, usually pH sensitive liposomes are prepared. Dioleoyl phosphatidylethanolamine (DOPE) is usually selected to prepare pH- sensitive liposomes, however, which is found to suffer from their difficulty to form liposomes by themselves. So in order to form stable liposomes, materials containing acidic groups must be added to DOPE. The liposomes established by the above membrane materials have pH-sensitivity, because at neutral pH, the fatty acid carboxyl ion can provide effective electrostatic repulsion, which makes the liposomes stable at lamellar phase, and at acidic pH, fatty acid carboxyl groups are protonated, causing the formation of the HII phase, which makes the liposomes unstable and easy to aggregate, fuse and release the contents.

- 25. • It has been observed that liposomes containing negatively charged phospholipids such as phosphatydilserine (PS,) phosphatidylglycerol (PG) can be quickly eliminated from the circulation system Charge • The main disadvantage of phospholipids as emulsifiers is that in the process of emulsification, sterilization and storage. • Natural lecithins are readily hydrolyzed to generate lysophospholipids which can lead to hemolysis after intravenous injection. Phospholipid mixtures derived from the egg yolk of birds and soybean have stronger emulsifying ability than single component. • However, using purified lecithins can reduce the generation of lysophospholipids. • The physical nature of lecithins and the resulting emulsion stability are changing a lot, depending on the sources and the degrees of purification of the emulsifiers. Lipid Mixtures

- 26. • Cholesterol is a membrane constituent widely found in biological systems which serves a unique purpose of modulating membrane fluidity, elasticity, and permeability. It literally fills in the gaps created by imperfect packing of other lipid. • The presence of cholesterol exerts a profound influence on the properties of the lipid bilayers of the liposomes. The addition of cholesterol to a fluid phase bilayer (mainly unsaturated lipids) decreases its permeability to water. • A liposome that is made from 100% unsaturated lipid in fluid phase can not hold its encapsulated content and the encapsulated water soluble drugs will leak out over time and therefore the addition of cholesterol is necessary in order to prevent the leakage of the encapsulated drug from the liposomes. Liposomes made from 100% saturated lipids are leak-proof in the absence of the cholesterol. • One of the main reasons for addition of cholesterol to liposomes that are made from saturated lipids is to decrease the phase transition temperature. The phase transition temperature of the mixture of the lipids in the liposomes will be decreased, but not eliminated, by the addition of cholesterol. Cholesterol

- 27. Synthetic and natural phospholipids have both advantages and disadvantages. The advantages of synthetic phospholipids are that the property is relatively stable, and purity is relatively high; the drawback is that the price is relatively high. However, the advantage of natural phospholipids is that the price is relatively low; the disadvantages are that the purity is difficult to control, and the nature is relatively unstable which can be metabolized to lysophospholipids in the process of usage and storage. So the source should be considered when choosing natural phospholipids to prepare the liposomes. For example, the content of unsaturated fatty acids in soybean phospholipids is higher than that in egg yolk phospholipids. Therefore, it is difficult to obtain quality controlled liposomes product using soybean lecithins. Source

- 28. • Stress induced hydration of phospholipids • Organization in to lamellar arrays • Results in to budding of lipid bilayer leading to down sizing SUV OLV 1. The budding theory Mechanism of Vesicle Formation

- 29. • Liposomes are formed when thin lipid films are hydrated • The hydrated lipid sheets detach during agitation and self-close to form large, multilamellar vesicles (LMV) 2.The bilayer phospholipids theory

- 30. METHOD OF PREPARATION OF LIPOSOMES

- 31. Involves loading of the entrapped agents before or during the manufacturing process Passive loading techniques Active or Remote loading techniques Certain types of compounds with ionisable groups and those with both lipid and water solubility, can be introduced into the liposomes after the formation of the intact vesicle.

- 32. General Method of Preparation of Liposome Lipid dissolve in organic solvent/ co-solvent Remove organic solvent under vacuum Film deposition Solid lipid mixture is hydrated by using aqueous buffer Lipid spontaneously swell & hydrate Liposome Post hydration Vortexing, Sonication, Freeze thawing & high pressure extrusion

- 33. MECHANICAL DISPERSION METHODS Aqueous volume enclosed using this method usually 5-10%, which is a very small proportion of total volume used for swelling . Therefore large quantity of water –soluble compound are wasted during swelling . On the other hand lipid soluble compound can be encapsulated to 100% efficacy, provided they are not present in quantities that are greater than the structural component of the membrane.

- 34. : 1.Lipid film hydration by hand shaking/non hand shaking Step-1 Lipid mixture of different phospholipid and charge components in chloroform: methanol solvent mixture (2:1v/v) is prepared first and then introduced into a round bottom flask with a ground glass neck. This flask is then attached to a rotary evaporator and rotated at 60 rpm. The organic solvent are evaporated at about 30 degree Celsius or above the transition temperature of the lipids used. The nitrogen is introduced into the evaporator and the pressure at the cylinder head is gradually raised till there is no difference between inside and outside the flask. The flask is then removed from the evaporator and fixed on to the manifold of lyophilizer to remove residual solvents.

- 35. Step-2 Hydration of lipid layer After releasing the vacuum and removal from the lyophilizer, the flask is flushed with nitrogen; 5 ml of saline phosphate buffer (containing solute to be entrapped) is added. The flask is attached to the evaporator again (flushed with N2) and rotated at room temperature and pressure at the same speed or below 60 rpm. The flask is left rotating for 30 minutes or until all lipid has been removed from the wall of the flask and has given homogenous milky –white suspension free of visible particles. The suspension is allowed to stand for a further 2 hours at room temperature or at a temperature above the transition temperature of the lipid in order to complete the swelling process to give MLVs. 1.Lipid film hydration by hand shaking/non hand shaking (Cont.)

- 36. Method described by reeves and dowben in 1996 by which large unicellular vesicles (LUVv) can be formed with higher entrapment volume. The procedure differs from hand shaken method in that it uses a stream of nitrogen to provide agitation rather than the rotationary movements. Solution of lipid in chloroform: methanol mixture is spread over the flat bottom conical flask. The solution is evaporated at room temperature by flow of nitrogen through the flask without disturbing the solution. After drying water saturated nitrogen is passed through the flask untill the opacity of the dried film disappears (15-20 mins). After hydration, lipid is swelled by addition of bulk fluid. The flask is inclined to one side, 10-20ml of 0.2 sucrose in distilled water (degassed) is introduced down the slide of the flask ,and the flask is slowly returned to upright orientation. The fluid is allowed to run gently over the lipid layer on the bottom of the flasks. Flask is flushed with nitrogen, sealed and allowed to stand for 2hours at 37 degrees Celsius. Take care not to disturb the flask in any way. After swelling, the vesicles are harvested by swirling the contents, to yield a milky –suspension. 1.Lipid film hydration by non shaking vesicles

- 37. 2. Microemulsification Micro fluidizer is used to prepare small MLVs from concentrated Lipid dispersion. Micro fluidizer pumps the fluid at very at very high pressure (10,000 psi), through a 5 micrometre orifice. Then, it is forced along defined micro channels which direct two streams of fluid collide together at the right angles at a very high velocity, thereby affecting an efficient transfer of energy. The lipids can be introduced into the fluidizer, either as large MLVs or as the slurry of a hydrated lipid in organic medium. The fluid collected can be recycled through the pump and the interaction chamber until vesicles of spherical dimensions are obtained. Diameter After a single pass, the size of vesicles is reduced to a size 0.1 and 0.2um.

- 38. This is the method in which Multi lamellar vesicles are transformed to the small unit lamellar vesicles. The ultrasonic irradiation is provided to the MLVs to get the SUVs. There are two methods used. a) Probe sonication method, b) Bath sonication method. The probe is employed for dispersion, which requires high energy in a small volume (e.g. High conc. of lipids or a viscous aqueous phase) while is more suitable for large volumes of diluted liquid. Probe tip sonicator provides high energy input to the liquid dispersion but suffer from overheating of liposomal dispersion causing lipid degradation. 3. Sonication method

- 39. 4. French Pressure Cell Method This method is having the mechanism of high pressure. This method will give the either uni- or oligo- lamellar Liposomes of intermediate size (30- 80nm). Liposomes are more stable compared to the sonicated Liposomes. Liposomes prepared by this method having less structural defects unlike sonicated liposome. This method is having some drawbacks are that initial high cost for the press and the pressure cell

- 40. 5. Membrane Extrusion method The technique can be used to process LUVs as well as MLVs. The size of Liposomes is reduced by gently passing them through a membrane filter of defined pore size achieved at much lower pressure (<100psi) In this process, the vesicle contents are exchanged with the dispersion medium during the breaking and resealing of phospholipids players as they pass through the polycarbonate membrane. The Liposomes produced by this technique have been termed LUVETs.

- 41. 6. Dried Reconstituted vesicle This method starts to freeze drying of a dispersion of empty SUVs. After freeze drying the freeze dried membrane is obtained. Then these freeze dried SUVs are rehydrated with the use of aqueous fluid containing the material to be entrapped. This leads to the formation of the solutes in uni- or oligo- lamellar vesicles

- 42. This method is based upon freezing of unilamellar dispersion (SUV). Then thawing by standing at room temperature for 15min. Finally subjecting to a brief Sonication cycle which considerably reduces the permeability of the Liposomes membrane. In order to prepare GIANT VESICLES of diameter between 10 and 50um, the freeze thaw technique has been modified to incorporate a dialysis step against hypo- osmolar buffer in the place of sonication. The method is simple, rapid and mild for entrapped solutes, and results in a high proportion of large unilamellar vesicle formation which are useful for study of membrane transport phenomenon. 7. Freeze Thaw Sonication

- 43. 1. Ethanol Injection Method A lipid solution of ethanol is rapidly injected to a vast excess of buffer. The MLVs are immediately formed. The drawbacks of the method are that the population is heterogeneous (30- 110 nm), liposomes are very dilute, it is difficult to remove all ethanol because it forms azeotrope with water and the possibility of various biologically active macromolecules to inactivation in the presence of even low amounts of ethanol.

- 44. 2. Ether Injection Method A solution of lipids dissolved in diethyl ether or ether/methanol mixture is slowly injected to an aqueous solution of the material to be encapsulated at 55-65°C or under reduced pressure. The subsequent removal of ether under vacuum leads to the formation of liposomes. The main drawbacks of the method are population is heterogeneous (70-190 nm) and the exposure of compounds to be encapsulated to organic solvents or high temperature

- 45. 3. Double emulsion vesicle

- 46. First water in oil emulsion is formed by brief sonication of a two phase system containing phospholipids in organic solvent (diethylether or isopropylether or mixture of isopropyl ether and chloroform) and aqueous buffer. The organic solvents are removed under reduced pressure, resulting in the formation of a viscous gel. The liposomes are formed when residual solvent is removed by continued rotary evaporation under reduced pressure. With this method high encapsulation efficiency up to 65% can be obtained in a medium of low ionic strength for example 0.01M NaCl. The method has been used to encapsulate small and large macromolecules. The main disadvantage of the method is the exposure of the materials to be encapsulated to organic solvents and to brief periods of sonication 4. Reverse phase evaporation vesicles

- 47. The detergents at their critical micelles concentrations have been used to solubilize lipids. As the detergent is removed the micelles become progressively richer in phospholipid and finally combine to form LUVs. The detergents can be removed by dialysis. The advantages of detergent dialysis method are excellent reproducibility and production of liposome populations which are homogenous in size. The main drawback of the method is the retention of traces of detergent(s) within the liposomes. A commercial device called LIPOPREP (Diachema AG, Switzerland) which is a version of dialysis system is available for the removal of detergents. Other techniques have been used for the removal of detergents: (a) by using Gel Chromatography involving a column of Sephadex G259 (b) by adsorption or binding of Triton X-100 (a detergent) to Bio-Beads SM-210 (c) by binding of octyl glucoside (a detergent) to Amberlite XAD-2 beads. Detergent Removal Method

- 48. The molecules of detergent are removed from mixed micelle by dialysis by lowering the concentration of detergent in bulk aqueous phase. eg: sodium cholate. octylglucoside. Dialysis Method Column Chromatography Removal of detergent is achieved by passing the dispersion over a sephadexg-25 column pre-saturated with constitutive lipids and pre-equilibrated with hydrating buffer. eg: deoxycholate.

- 49. In active loading, drug internalization into preformed liposomes is typically driven by a transmembrane pH gradient. The pH outside the liposome allows some of the drug to exist in an unionized form, able to migrate across the lipid bilayer. Once inside the liposome, the drug becomes ionized due to the differing pH and becomes trapped there ACTIVE (REMOTE) LOADING

- 51. • Stabilization aspect for physical instability of liposomes • Chemical stability • Biological stability of liposomes Stability Consideration

- 52. • Two different types of chemical degradation • Oxidation of the unsaturated acyl chains, • Hydrolysis of the ester bonds linking the fatty acids to the glycerol backbone • The level of oxidation can be kept to a minimum by taking some precautions like starting with freshly purified lipids and freshly distilled solvents, avoiding procedures involving high temperatures, carrying out the manufacturing process in the absence of oxygen, deoxygenating the aqueous solutions by passing nitrogen, storing all liposome suspensions in an inert atmosphere and including an antioxidant, e.g. α-tocopherol, a common non-toxic dietary lipid, as a component of the lipids membrane. An alternative solution to the oxidation problem is to reduce the level of oxidizable lipids in the membrane by using saturated lipids instead of the unsaturated ones. Also, the mono-unsaturated ones have much less tendency of oxidation than the polyunsaturated ones. Thus; sphingomyelins, usually having only one double bond, are expected to degrade more slowly than other mammalian origin lipids. Entirely synthetic and saturated phospholipids; DMPC, DPPC and DSPC, can also be considered as a solution for the oxidative degradation of liposomes. Chemical Stability:

- 53. • Hydrolysis type of chemical degradation of the ester linkages in the phospholipid structure occurs most slowly at pH values close to neutral. • In general, the rate of hydrolysis has a “V shaped” dependence, with a minimum at pH 6.5 and an increased rate at both higher and lower pH. • In the active loading of drugs, low pH levels are required which triggers the hydrolysis. This hydrolysis kind of chemical degradation is also very effective on the aqueous solutions of liposome due to the presence of water. • Temperature also triggers the hydrolysis of the lipids which creates the need for refrigeration. In order to keep hydrolysis to a minimum during active loading, attention must be paid for the removal of residual solvent from the dried lipids. To avoid hydrolysis, instead of ester linked lipids, the usage of ether linkage containing lipids (e.g. found in the membrane of halophilic bacteria) would be an absolute solution .Another chemical degradation, oxidation of the lipids in the liposome structures can be prevented by the addition of small amounts of antioxidants during the manufacturing steps. Chemical Stability:

- 54. • The physical degradation, leakage and fusion of liposomes, can occur as a result of the lattice defects in the membrane introduced during the manufacture, particularly in SUVs that are prepared below the membrane phase transition temperature. • Annealing process, incubating the liposomes at a higher temperature than the phase transition temperature, can wipe out these defects by equalizing the differences in packing density between opposite sides of the bilayers. • Even in annealed vesicles, aggregation and fusion can occur over a long period of time. • In neutral liposomes, aggregation takes place because of the van der Waals interactions and because of the increased surface area it tends to be more pronounced in large liposomes. • The simplest solution to overcome this aggregation is to add a small amount of negatively charged phospholipid (e.g. 10% PA or PG) to the liposome composition Physical Stability:

- 55. • SUVs have much more tendency to fusion when compared to large liposomes due to the presence of stress arising from the high curvature of the membrane. • Since this can occur specifically at the transition temperature of the membrane, it would be better to store these liposomes at a temperature much lower than the transition temperature of the lipids. • For example, SUVs should be stored above their transition temperature for no longer than 24 hours but LUVs can be stored for a longer period of time if the temperature of the solution is kept in a range of 4-8 0C for approximately 1 week before the leakage of the encapsulated material starts due to the hydrolytic degradation on the membrane structure . • Also, addition of cholesterol to the phospholipid mixture would be a solution to reduce or eliminate the transition. • The presence of cholesterol prevents packing and aggregation by inducing orientation and more rigidity to the phospholipids. Other than cholesterol, peptide incorporation to the lipid membrane also enables the lipid membrane to be more rigid at physiological temperature. • Permeability of liposome membranes depends highly on the membrane lipid composition, as well as on the encapsulated material. Large polar or ionic molecules will be retained much more efficiently than low molecular weight lipophilic compounds. Generally, for both type of encapsulated material, a rigid, more saturated membrane with a higher ratio of cholesterol forms the most stable lipid membrane concerning the leakage of the encapsulated material. Physical Stability:

- 56. • Biological liposome stability plays important roles at various stages of drug delivery. However, liposomes are somewhat biologically unstable as a parenteral drug delivery system owing to their rapid uptake and clearance from circulation by cells of the mononuclear phagocytic system (MPS) located mainly in the liver and spleen. • Biological stability of liposomes is dependent on the presence of agents such as proteins that interact with liposomes upon application to the subject and the administration route. • There have been many strategies to enhance the biological stability of liposomes that improve the liposomal drug delivery in vivo and increase the circulation time in blood stream. • The complexation between polymers and liposomes has been studied as a way to increase the long-term stability of liposomes. • Grafting hydrophilic polymers onto the head groups of phospholipids, or the addition of water soluble polymers containing several hydrophobic groups has been shown to increase the circulation time in vivo, as well as to inhibit liposome fusion . • These kinds of liposomes are called stealth liposome or sterically stabilized liposomes . The steric repulsion of these liposomes stabilizes the liposomes against aggregation. • One of the most popular and successful methods to obtain long-circulating biologically stable liposomes is to coat the surface of the liposome with poly(ethylene glycol), PEG. Biological Stability:

- 57. • It is important to estimate the amount of drug encapsulated within liposomes. • This is easier to estimate by centrifugation in case of MLVs compared to LUVs and SUVs. • The various methods used to separate non-encapsulated drug are • eg: Dialysis. • Gel chromatography. Removal of unentrapped drug from liposomes:

- 58. • For the characterization of chemical properties, phospholipids can be quantitatively in terms of concentration either by Bartlett Assay or Stewart Assay. • The phospholipid hydrolysis might be followed by HPLC where the column outflow can be monitored continuously by UV absorbance to obtain a quantitative record of the eluted components. • Moreover, the phospholipid oxidation can also be followed by a number of techniques i.e., • UV absorbance method, • TBA method (2-thiobarbutiric acid) (for endoperoxides), • Iodometric method (for hydroperoxides) and • GLC (gas-liquid chromatography) method. Characterization of Liposome

- 59. Bartlett Assay • The principle of the Bartlett assay is based on the colorimetric determination of inorganic phosphate. The phospholipid content of liposomes can be determined after destruction of the phospholipid with perchloric acid to inorganic phosphate. The inorganic phosphate is converted to phospho-molybdic acid by the addition of ammonium molybdate, which is reduced to a blue colored complex by 4-amino-2-naphthyl-4-sulfonic acid during heating. This compound can be determined colorimetrically at 830 nm. Stewart Assay • In Stewart assay, the phospholipid forms a complex with ammonium ferrothiocyanate in organic solution. The advantage of this method is that the presence of inorganic phosphate does not interfere with the assay.

- 60. • The most direct method for determination of liposome size is the electron microscopy due to the possibility of viewing the liposomes individually and obtaining the exact information about the liposome population over the whole range of sizes. • As liposomes do not naturally create a contrast to be visible by electron microscopy, either cryo-TEM should be used or staining of the liposome sample is required. • Either way, it is a very time consuming method and it requires equipment's that may not always be immediately accessible. • The other method for the determination of liposome size, dynamic light scattering is very simple and rapid to perform but it measures an average size of liposome bulk. • More recently, atomic force microscopy is also used to determine the morphology, size and stability of liposomal structures. • All these size determination methods are very expensive. • If only an approximate size range is required, gel exclusion chromatography might be suitable. Vesicle Size And Size Distribution:

- 61. • Electrostatic stabilization of liposomes may be a desirable feature to prevent fusion. • The surface charge on the liposomes is measured by zeta-potential measurements. • These measurements are useful in determination of the in vivo behavior of liposomes. • Often zeta potential values <-25 mV or >+25 mV are considered stable • However, charged liposomes have the disadvantage of being unstable in biological conditions. Surface Charge:

- 62. • Membrane phospholipids undergo temperature dependent reversible phase transitions from gel to liquid crystaline state. • These have been documented by freeze fracture electron microscopy and DSC. • Tm of the phospholipid affects the membrane permeability, leakage and stability of liposomes. • Tm can be altered by using phospholipid mixtures or by adding cholesterol. Phase Behaviour of Liposomes:

- 63. • Entrapped volume is a crucial parameter that governs the morphology of liposomes. • This internal volume is defined as the aqueous entrapped volume per unit quantity of lipids. • The most promising way to determine the internal volume is to measure the quantity of water by replacing external medium (water) with a spectrophotometrically inert fluid (i.e. deuterium oxide) and then measuring water signal by NMR Entrapped volume of Liposomes:

- 64. • It is essential to measure the quantity of the encapsulated material inside liposomal structures before studying the behavior of this encapsulated material physically and biologically since the effects observed experimentally will be dose related. • After the removal of the nonencapsulated material by the separation techniques the quantity of material remained can be assumed as 100% encapsulated. • Minicolumn centrifugation and protamine aggregation methods are the general separation procedures that are commonly used Encapsulation Efficiency:

- 65. • In vitro drug release from liposomal systems was determined using dialysis sacks. • Release test for a targeted liposome would need to show that liposome is stable until uptake at the site. In-vitro Drug Release

- 66. • Liposomes as drug or protein delivery vehicles. • Liposome in antimicrobial, antifungal(lung therapeutics) and antiviral (anti HIV) therapy. • In tumour therapy. • In gene therapy. • In immunology. • Liposomes as artificial blood surrogates. • Liposomes as radiopharmaceutical and radiodiagnostic carriers. • Liposomes in cosmetics and dermatology. Application of Liposome