Topic 2 machining 160214

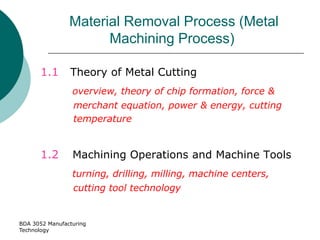

- 1. BDA 3052 Manufacturing Technology Material Removal Process (Metal Machining Process) 1.1 Theory of Metal Cutting overview, theory of chip formation, force & merchant equation, power & energy, cutting temperature 1.2 Machining Operations and Machine Tools turning, drilling, milling, machine centers, cutting tool technology

- 2. BDA 3052 Manufacturing Technology Material Removal Processes Introduction It is shaping operations, it remove material from a starting workpart so the remaining part has the desired geometry Divided into three main groups: 1) Machining – material removal by a sharp cutting tool, e.g., turning, milling, drilling 2) Abrasive processes – material removal by hard, abrasive particles, e.g., grinding 3) Nontraditional processes - various energy forms other than sharp cutting tool to remove material

- 3. BDA 3052 Manufacturing Technology Why Machining is Important Variety of work materials can be machined Most frequently used to cut metals Variety of part shapes and special geometric features possible, such as: Screw threads Accurate round holes Very straight edges and surfaces Good dimensional accuracy and surface finish

- 4. BDA 3052 Manufacturing Technology Disadvantages with Machining Wasteful of material Chips generated in machining are wasted material, at least in the unit operation Time consuming A machining operation generally takes more time to shape a given part than alternative shaping processes, such as casting, powder metallurgy, or forming

- 5. BDA 3052 Manufacturing Technology Machining in Manufacturing Sequence Generally performed after other manufacturing processes, such as casting, forging, and bar drawing Other processes create the general shape of the starting workpart Machining provides the final shape, dimensions, finish, and special geometric details that other processes cannot create

- 6. BDA 3052 Manufacturing Technology Machining Nomenclature of single point tool

- 7. BDA 3052 Manufacturing Technology Seven elements of single-point tool geometry; and (b) the tool signature convention that defines the seven elements.

- 8. BDA 3052 Manufacturing Technology Simplified 2-D model of machining that describes the mechanics of machining fairly accurately Figure 21.6 Orthogonal cutting: (a) as a three-dimensional process. Orthogonal Cutting Model

- 9. BDA 3052 Manufacturing Technology Orthogonal and Oblique cutting

- 10. Assumptions in orthogonal cutting (Merchant theory) 01.The tool is perfectly sharp and no contact along clearance face. 02. The shear surface is a plane extending upward from the cutting edge. 03.The cutting edge is a straight line, extending perpendicular to the direction of motion and generates a plane surface as the work moves past it. 04.The chip does not flow to either side. 05.The depth of cut is constant. 06.Width of the tool is greater than the work piece. 07.The work moves relative to the tool with uniform velocity. 08.A continuous chip is produced with no built up edge. BDA 3052 Manufacturing Technology

- 11. Assumptions in orthogonal cutting (Merchant theory) 09. Chip is assume to shear continuously across plane AB on which the shear stress reaches the value of shear flow stress. 10.Width of chip is remains equal to the width of the work piece. i.e. Plane strain conditions exist. BDA 3052 Manufacturing Technology

- 12. Difference between orthogonal and oblique cutting Orthogonal cutting Oblique cutting 01.The cutting edge of the tool is perpendicular to the direction of the tool travel. The cutting edge is inclined at angle with the normal direction of the tool travel. 02. The cutting edge clears the width of the work piece on either ends. The cutting edge may or may not clear the width of the workpiece. 03. The chip flows over the tool. The chip coils in tight. The chip flows on the tool face making an angle with the normal cutting edge. The chip flows side ways in a long curl. 04. Only two components of the cutting force acting on the tool. Three components of the forces acting on the tool. 05.Maximum chip thickness occurs at the middle. Maximum chip thickness may not occur at middle. 06. For the given feed rate and DOC, the force which act or shears the metal acts on a smaller area and therefore, the heat developed per unit area due to friction along the tool work interface is less and the tool life is less. It acts on larger area and thus tool life is more.

- 13. BDA 3052 Manufacturing Technology Cutting action involves shear deformation of work material to form a chip As chip is removed, new surface is exposed (a) A cross-sectional view of the machining process, (b) tool with negative rake angle; compare with positive rake angle in (a). Machining

- 14. BDA 3052 Manufacturing Technology Cutting Process in Turning

- 15. BDA 3052 Manufacturing Technology Cutting Process in Turning

- 16. BDA 3052 Manufacturing Technology Relationship between chip thickness, rake angle and shear plane angle )cos( sin )cos( sin s s l l r

- 17. BDA 3052 Manufacturing Technology Chip Thickness Ratio where r = chip thickness ratio; to = thickness of the chip prior to chip formation; and tc = chip thickness after separation Chip thickness after cut always greater than before, so chip ratio always less than 1.0 c o t t r

- 18. BDA 3052 Manufacturing Technology Example of Problem In a machining operation that approximates orthogonal cutting, the cutting tool has a rake angle = 10. The chip Thickness before the cut to = 0.50 mm and the chip thickness after the cut tc = 1.125 mm. Calculate the shear plane angle and the shear strain in the operation. Answer : = 25.4 = 2.386

- 19. BDA 3052 Manufacturing Technology Example of Problem 2 In an orthogonal cutting operation, the tool has a rake angle = 15. The chip thickness before the cut = 0.30 mm and the cut yields a deformed chip thickness = 0.65 mm. Calculate (a) the shear plane angle and (b) the shear strain for the operation.

- 20. BDA 3052 Manufacturing Technology Shear strain during chip formation: (a) chip formation depicted as a series of parallel plates sliding relative to each other, (b) one of the plates isolated to show shear strain, and (c) shear strain triangle used to derive strain equation. Shear Strain in Chip Formation

- 21. BDA 3052 Manufacturing Technology Shear Strain Shear strain in machining can be computed from the following equation, based on the preceding parallel plate model: = tan( - ) + cot where = shear strain, = shear plane angle, and = rake angle of cutting tool BD DCAD BD AC

- 22. BDA 3052 Manufacturing Technology Example of Problem 2 In an orthogonal cutting operation, the tool has a rake angle = 15. The chip thickness before the cut = 0.30 mm and the cut yields a deformed chip thickness = 0.65 mm. Calculate (a) the shear plane angle and (b) the shear strain for the operation.

- 23. BDA 3052 Manufacturing Technology More realistic view of chip formation, showing shear zone rather than shear plane. Also shown is the secondary shear zone resulting from tool-chip friction. Chip Formation

- 24. BDA 3052 Manufacturing Technology Four Basic Types of Chip in Machining 1. Discontinuous chip 2. Continuous chip 3. Continuous chip with Built-up Edge (BUE) 4. Serrated chip

- 25. BDA 3052 Manufacturing Technology Brittle work materials Low cutting speeds Large feed and depth of cut High tool-chip friction 1. Discontinuous Chip

- 26. BDA 3052 Manufacturing Technology Ductile work materials High cutting speeds Small feeds and depths Sharp cutting edge Low tool-chip friction 2. Continuous Chip

- 27. BDA 3052 Manufacturing Technology Ductile materials Low-to-medium cutting speeds Tool-chip friction causes portions of chip to adhere to rake face BUE forms, then breaks off, cyclically Continuous with BUE

- 28. BDA 3052 Manufacturing Technology Semicontinuous - saw-tooth appearance Cyclical chip forms with alternating high shear strain then low shear strain Associated with difficult-to-machine metals at high cutting speeds Serrated Chip Figure 21.9 (d) serrated.

- 29. BDA 3052 Manufacturing Technology Higher shear plane angle means smaller shear plane which means lower shear force, cutting forces, power, and temperature Effect of shear plane angle : (a) higher with a resulting lower shear plane area; (b) smaller with a corresponding larger shear plane area. Note that the rake angle is larger in (a), which tends to increase shear angle according to the Merchant equation Effect of Higher Shear Plane Angle

- 30. BDA 3052 Manufacturing Technology Friction force F and Normal force to friction N Shear force Fs and Normal force to shear Fn Forces in metal cutting: (a) forces acting on the chip in orthogonal cutting Forces Acting on Chip

- 31. BDA 3052 Manufacturing Technology Resultant Forces Vector addition of F and N = resultant R Vector addition of Fs and Fn = resultant R' Forces acting on the chip must be in balance: R‘’ must be equal in magnitude to R R’ must be opposite in direction to R R’ must be collinear with R

- 32. BDA 3052 Manufacturing Technology Cutting Forces

- 33. BDA 3052 Manufacturing Technology Cutting Forces

- 34. BDA 3052 Manufacturing Technology Cutting Forces

- 35. BDA 3052 Manufacturing Technology Coefficient of Friction Coefficient of friction between tool and chip: Friction angle related to coefficient of friction as follows: N F tan -(1) -(2)

- 36. BDA 3052 Manufacturing Technology Shear Stress Shear stress acting along the shear plane: sin wt A o s where As = area of the shear plane Shear stress = shear strength of work material during cutting s s A F S -(3) -(4)

- 37. BDA 3052 Manufacturing Technology F, N, Fs, and Fn cannot be directly measured Forces acting on the tool that can be measured: Cutting force Fc and Thrust force Ft Forces in metal cutting: (b) forces acting on the tool that can be measured Cutting Force and Thrust Force

- 38. BDA 3052 Manufacturing Technology Merchant’s circle diagram

- 39. BDA 3052 Manufacturing Technology Merchant’s circle diagram

- 40. BDA 3052 Manufacturing Technology Forces in Metal Cutting Equations can be derived to relate the forces that cannot be measured to the forces that can be measured: F = Fc sin + Ft cos (5) N = Fc cos - Ft sin (6) Fs = Fc cos - Ft sin (7) Fn = Fc sin + Ft cos (8) Based on th ese calculated force, shear stress and coefficient of friction can be determined

- 41. BDA 3052 Manufacturing Technology Example of Problem 3 Cutting force = 1559 N Thrust force = 1271 N Width of cutting = 3 mm Rake angle = 10 Shear plane angle = 25.4 Original Thickness = 0.5 mm Determine the shear strength of the work material. shear stress, S / shear strength, = 247 N/mm2

- 42. BDA 3052 Manufacturing Technology Forces in Metal Cutting From equation 3, the force diagram (Merchant ‘s Circle Diagram), can be used to derived the following equations: )cos( )cos( )cos(sin )cos( so c FwSt F )cos( )sin( )cos(sin )sin( so t FwSt F

- 43. BDA 3052 Manufacturing Technology The Merchant Equation From equation 3, 4 and 7, Merchant Equation for shear stress can be expressed as, )sin/( sincos o tc t FF

- 44. BDA 3052 Manufacturing Technology The Merchant Equation Of all the possible angles at which shear deformation can occur, the work material will select a shear plane angle that minimizes energy, given by Derived by Eugene Merchant Based on orthogonal cutting, but validity extends to 3-D machining 22 45

- 45. BDA 3052 Manufacturing Technology What the Merchant Equation Tells Us To increase shear plane angle Increase the rake angle Reduce the friction angle (or coefficient of friction) 22 45

- 46. BDA 3052 Manufacturing Technology Power and Energy Relationships A machining operation requires power The power to perform machining can be computed from: Pc = Fc where Pc = cutting power (Nm/s); Fc = cutting force (N); and = cutting speed (m/min)

- 47. BDA 3052 Manufacturing Technology Power and Energy Relationships In U.S. customary units, power is traditional expressed as horsepower HPc = Fc/33,000 where HPc = cutting horsepower, hp

- 48. BDA 3052 Manufacturing Technology Power and Energy Relationships Gross power to operate the machine tool Pg or HPg is given by or where E = mechanical efficiency of machine tool Typical E for machine tools 90% E P P c g E HP HP c g

- 49. BDA 3052 Manufacturing Technology Unit Power in Machining Useful to convert power into power per unit volume rate of metal cut Called unit power, Pu or unit horsepower, HPu or where MRR = material removal rate (mm3/s) MRR P P c U MRR HP HP c u

- 50. BDA 3052 Manufacturing Technology Specific Energy in Machining Unit power is also known as the specific energy U Units for specific energy are typically N-m/mm3 or J/mm3 wt F wvt vF MRR P PU o c o cc u

- 51. BDA 3052 Manufacturing Technology Cutting Temperature Approximately 98% of the energy in machining is converted into heat This can cause temperatures to be very high at the tool-chip The remaining energy (about 2%) is retained as elastic energy in the chip

- 52. BDA 3052 Manufacturing Technology Cutting Temperature is Important High cutting temperatures 1. Reduce tool life 2. Produce hot chips that pose safety hazards to the machine operator 3. Can cause inaccuracies in part dimensions due to thermal expansion of work material

- 53. BDA 3052 Manufacturing Technology Cutting Temperature Analytical method derived by Nathan Cook from dimensional analysis using experimental data for various work materials where T = temperature rise at tool-chip interface; U = specific energy; v = cutting speed; to = chip thickness before cut; C = volumetric specific heat of work material; K = thermal diffusivity of work material 3330 40 . . K vt C U T o

- 54. BDA 3052 Manufacturing Technology Example Problem 6 Cutting speed = 100 m/min Chip original thickness = 0.5 mm Thermal diffusivity = 50 mm2/s Specific Energy = 1.038 Volumetric specific heat work material = 3 x10-3 J/mm3 Find the mean temperature rise at the tool-chip Interface.

- 55. BDA 3052 Manufacturing Technology Cutting Temperature Experimental methods can be used to measure temperatures in machining Most frequently used technique is the tool-chip thermocouple Using this method, Ken Trigger determined the speed-temperature relationship to be of the form: T = K vm where T = measured tool-chip interface temperature, and v = cutting speed K and m depend on the cutting conditions and work material

- 56. Machining A material removal process in which a sharp cutting tool is used to mechanically cut away material so that the desired part geometry remains Most common application: to shape metal parts Most versatile of all manufacturing processes in its capability to produce a diversity of part geometries and geometric features with high precision and accuracy Casting can also produce a variety of shapes, but it lacks the precision and accuracy of machining

- 57. Rotational - cylindrical or disk-like shape Nonrotational (also called prismatic) - block-like or plate-like Machined parts are classified as: (a) rotational, or (b) nonrotational, shown here by block and flat parts. Classification of Machined Parts

- 58. Machining Operations and Part Geometry Each machining operation produces a characteristic part geometry due to two factors: 1. Relative motions between tool and workpart • Generating – part geometry determined by feed trajectory of cutting tool 2. Shape of the cutting tool • Forming – part geometry is created by the shape of the cutting tool

- 59. Figure 22.2 Generating shape: (a) straight turning, (b) taper turning, (c) contour turning, (d) plain milling, (e) profile milling. Generating Shape

- 60. Forming to create shape: (a) form turning, (b) drilling, and (c) broaching. Forming to Create Shape

- 61. Combination of forming and generating to create shape: (a) thread cutting on a lathe, and (b) slot milling. Forming and Generating

- 62. Turning Single point cutting tool removes material from a rotating workpiece to generate a cylinder Performed on a machine tool called a lathe Variations of turning performed on a lathe: Facing Contour turning Chamfering Cutoff Threading

- 64. Turning Operation Close-up view of a turning operation on steel using a titanium nitride coated carbide cutting insert (photo courtesy of Kennametal Inc.)

- 65. Tool is fed radially inward Facing

- 66. Instead of feeding tool parallel to axis of rotation, tool follows a contour that is other than straight, thus creating a contoured shape Contour Turning

- 67. Cutting edge cuts an angle on the corner of the cylinder, forming a "chamfer" Chamfering

- 68. Tool is fed radially into rotating work at some location to cut off end of part Cutoff

- 69. Tool is fed radially into rotating work at some location to cut off end of part Cutoff

- 70. Pointed form tool is fed linearly across surface of rotating workpart parallel to axis of rotation at a large feed rate, thus creating threads Threading

- 71. The rotational speed in turning related to the desired cutting speed at the surface of the cylindrical workpiece by the equation: N = rotational speed, rev/min; = cutting speed, m/min, And Do = original diameter of the part, m. Cutting Conditions in Turning - 1 D N

- 72. The change in diameter is determined by the depth of cut, d: Do – Df = 2d Do = original diameter, mm; Df = final diameter, mm d = depth of cut Cutting Conditions in Turning - 2

- 73. The feed in turning is generally expressed in mm/rev. This feed can be converted to linear travel rate in mm/min by the formula: fr = Nf fr = feed rate, mm/min; f = feed mm/rev Cutting Conditions in Turning - 3

- 74. The time to machine from one end of a cylindrical workpart to the other is given by: Tm = L/fr Tm = time of actual machining, minutes; and L = length of the cylindrical workpart, mm Cutting Conditions in Turning - 4

- 75. The volumetric rate of material removal rate can be most conveniently determined by the following equation: MRR = vfd MRR = material removal rate, mm3/min, f = feed, mm Cutting Conditions in Turning - 5

- 76. A cylindrical workpart 200 mm in diameter and 700 mm long is to be turned in an engine lathe. Cutting conditions are as follows: cutting speed is 2.30 m/s, feed is 0.32 mm/rev, and depth of cut is 1.80 mm. Determine (a) cutting time, and (b) metal removal rate. Cutting Conditions in Turning Problem 1

- 77. A cylindrical workpart 200 mm in diameter and 700 mm long is to be turned in an engine lathe. Cutting conditions are as follows: cutting speed is 2.30 m/s, feed is 0.32 mm/rev, and depth of cut is 1.80 mm. Determine (a) cutting time, and (b) metal removal rate. Cutting Conditions in Turning Problem 1

- 78. A work materials are to be turned to final size of 175 mm length having diameter of 60 mm. Total length of the work material is 300 mm. A single point tool having a certain degree of rake angle is used. The work material rotates at 1400 RPM. The feed is 0.35 mm / revolution. Final size of the work material is 51 mm. Calculate: 1. Cutting velocity, 2. Time taken to machine to the length of 55 mm, 3. Total Material removal rate to get 51 mm diameter. Cutting Conditions in Turning Problem 2

- 79. Milling Machining operation in which work is fed past a rotating tool with multiple cutting edges Axis of tool rotation is perpendicular to feed Creates a planar surface Other geometries possible either by cutter path or shape Other factors and terms: Interrupted cutting operation Cutting tool called a milling cutter, cutting edges called "teeth" Machine tool called a milling machine

- 80. Peripheral Milling vs. Face Milling Peripheral milling Cutter axis parallel to surface being machined Cutting edges on outside periphery of cutter Face milling Cutter axis perpendicular to surface being milled Cutting edges on both the end and outside periphery of the cutter

- 81. METHODS OF MILLING-1 1) Up milling is also referred to as conventional milling. The direction of the cutter rotation opposes the feed motion. For example, if the cutter rotates clockwise , the workpiece is fed to the right in up milling.

- 82. METHODS OF MILLING-2 2) Down milling is also referred to as climb milling. The direction of cutter rotation is same as the feed motion. For example, if the cutter rotates counterclockwise , the workpiece is fed to the right in down milling

- 83. Basic form of peripheral milling in which the cutter width extends beyond the workpiece on both sides Slab Milling

- 84. Width of cutter is less than workpiece width, creating a slot in the work Slotting

- 85. Cutter overhangs work on both sides Conventional Face Milling

- 86. Form of end milling in which the outside periphery of a flat part is cut Profile Milling

- 87. Another form of end milling used to mill shallow pockets into flat parts Pocket Milling

- 88. Ball-nose cutter fed back and forth across work along a curvilinear path at close intervals to create a three dimensional surface form Surface Contouring

- 89. Cutter diameter is less than work width, so a slot is cut into part End Milling

- 90. Machining Centers Highly automated machine tool can perform multiple machining operations under CNC control in one setup with minimal human attention Typical operations are milling and drilling Three, four, or five axes Other features: Automatic tool-changing Pallet shuttles Automatic workpart positioning

- 91. High speed face milling using indexable inserts (photo courtesy of Kennametal Inc.). Milling Operation

- 92. The cutting speed is determined at the outside diameter of a milling cutter. N = rotational speed, rev/min; = cutting speed, m/min, And Do = outside diameter of a milling cutter,mm. Cutting Conditions in Milling - 1 D N

- 93. The feed, f in milling is usually given as a feed per cutter tooth; called the chip load, it represents the size of the chip formed by each cutting edge. fr = Nnt f fr = feed rate, mm/min; N = spindle speed, rev/min; nt = number of teeth on the cutter; f = chip load in mm/tooth Cutting Conditions in Milling - 2

- 94. The feed, f in milling is usually given as a feed per cutter tooth; called the chip load, it represents the size of the chip formed by each cutting edge. fr = Nnt f fr = feed rate, mm/min; N = spindle speed, rev/min; nt = number of teeth on the cutter; f = chip load in mm/tooth Cutting Conditions in Milling - 2

- 95. The material removal rate, MRR = wdfr w = width; d = depth of cut; fr = feed rate, mm/min; Cutting Conditions in Milling - 3

- 97. Approach distance A, to reach full cutter depth given by: d = depth of cut, mm, and D = diameter of the milling cutter, mm Cutting Conditions in Milling - 4 )( dDdA

- 98. The time to mill the workiece Tm is therefore; Cutting Conditions in Milling - 5 r m f AL T

- 99. Face Milling – cutter is centered

- 100. Where A and O are each to half the cutter diameter; A = O = D/2 D= cutter diameter, mm Cutting Conditions in Milling - 6

- 101. Face Milling – cutter is offset

- 102. Where A and O are each to half the cutter diameter; w= width of the cut, mm Cutting Conditions in Milling - 7 )( wDwOA

- 103. The time to mill the workiece in face milling,Tm is therefore; Cutting Conditions in Milling - 8 r m f AL T 2

- 104. A peripheral milling operation is performed on the top surface of a rectangular workpart which is 400 mm long by 60 mm wide. The milling cutter, which is 80 mm in diameter and has five teeth, overhangs the width of the part on both sides. The cutting speed is 70 m/min, the chip load is 0.25 mm/tooth, and the depth of cut is 5.0 mm. Determine (a) the time to make one pass across the surface, and (b) the maximum material removal rate during the cut. Cutting Conditions in Milling Problem 1

- 105. A face milling operation is performed to finish the top surface of a steel rectangular work piece 350 mm long by 55 mm wide. The milling cutter has four teeth (cemented carbide inserts) and a 85 mm diameter. Cutting conditions are: v = 600 m/min, f = 0.35 mm / tooth, and d = 3.5 mm. Determine: a) the time to make one pass across the surface. b) the metal removal rate during the cut. Cutting Conditions in Milling Problem 2

- 106. Creates a round hole in a workpart Compare to boring which can only enlarge an existing hole Cutting tool called a drill or drill bit Machine tool: drill press Drilling

- 107. Through-holes - drill exits opposite side of work Blind-holes – does not exit work opposite side Two hole types: (a) through-hole, and (b) blind hole. Through Holes vs. Blind Holes

- 108. Used to slightly enlarge a hole, provide better tolerance on diameter, and improve surface finish Reaming

- 109. Used to provide internal screw threads on an existing hole Tool called a tap Tapping

- 110. Provides a stepped hole, in which a larger diameter follows smaller diameter partially into the hole Counterboring

- 111. Letting N represent the spindle rev/min, = cutting speed, m/min; D = the drill diameter,mm. Cutting Conditions in Drilling - 1 D N

- 112. Feed can be converted to feed rate using the the same equation as for turning: fr = Nf fr = feed rate, mm/min; N = spindle speed, rev/min; f = feed in drilling, mm/rev Cutting Conditions in Drilling - 2

- 113. The time to drill through holes; Tm= machining time, min; t = work thickness, mm; fr = feed rate, mm/min Cutting Conditions in Drilling - 3 r m f At T

- 114. The allowance is given by; A = approach allowance, mm; = drill point angle Cutting Conditions in Drilling - 4 2 90tan5.0 DA

- 115. The time to drill blind holes; Tm= machining time, min; d = hole depth, mm; fr = feed rate, mm/min Cutting Conditions in Drilling - 5 r m f d T

- 116. A drilling operation is to be performed with a 12.7 mm diameter twist drill in a steel workpart. The hole is a blind hole at a depth of 60 mm and the point angle is 118. The cutting speed is 25 m/min and the feed is 0.30 mm/rev. Determine (a) the cutting time to complete the drilling operation, and (b) metal removal rate during the operation, after the drill bit reaches full diameter. Cutting Conditions in Drilling Problem 1

- 117. CUTTING TOOL TECHNOLOGY 1. Tool Life 2. Tool Materials 3. Tool Geometry 4. Cutting Fluids

- 118. Cutting Tool Technology Two principal aspects: 1. Tool material 2. Tool geometry

- 119. Three Modes of Tool Failure 1. Fracture failure Cutting force becomes excessive and/or dynamic, leading to brittle fracture 2. Temperature failure Cutting temperature is too high for the tool material 3. Gradual wear Gradual wearing of the cutting tool

- 120. Preferred Mode: Gradual Wear Fracture and temperature failures are premature failures Gradual wear is preferred because it leads to the longest possible use of the tool Gradual wear occurs at two locations on a tool: Crater wear – occurs on top rake face Flank wear – occurs on flank (side of tool)

- 121. Figure 23.1 Diagram of worn cutting tool, showing the principal locations and types of wear that occur. Tool Wear

- 122. Figure 23.2 Crater wear, (above), and flank wear (right) on a cemented carbide tool, as seen through a toolmaker's microscope (photos by K. C. Keefe, Manufacturing Technology Lab, Lehigh University).

- 123. FLANK WEAR and BUE

- 124. CRATER WEAR

- 125. BUILT UP EDE

- 126. Taylor Tool Life Equation Relationship is credited to F. W. Taylor CvT n where v = cutting speed; T = tool life; and n and C are parameters that depend on feed, depth of cut, work material, tooling material, and the tool life criterion used n is the slope of the plot C is the intercept on the speed axis at one minute tool life

- 127. Tool Life Criteria in Production 1. Complete failure of cutting edge 2. Visual inspection of flank wear (or crater wear) by the machine operator 3. Fingernail test across cutting edge 4. Changes in sound emitted from operation 5. Chips become ribbon-like, stringy, and difficult to dispose of 6. Degradation of surface finish 7. Increased power 8. Workpiece count 9. Cumulative cutting time

- 128. Tool Materials Tool failure modes identify the important properties that a tool material should possess: Toughness - to avoid fracture failure Hot hardness - ability to retain hardness at high temperatures Wear resistance - hardness is the most important property to resist abrasive wear