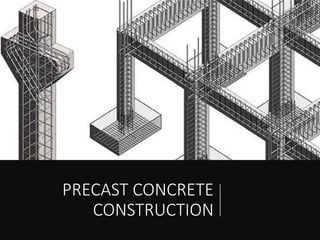

Precast concrete construction

- 2. What isPrecast Concrete? Precast concrete means a concrete member that is cast and cured at a location other than its final designated location. The use of reinforced concrete is a relatively recent invention, usually dated to 1848 when jean- Louis Lambot became the first to use it. Joseph Monier, a French gardener, patented a design for reinforced garden tubs in 1868, and later patented reinforced concrete beams and posts for railway and road guardrails.

- 4. INTRODUCTION : 4 + +/- Additives = +Concrete + CONCRETE MIX DEPENDS ON : Workability 5 categories: •Very high •High •Medium •Low •Very low Strength Finished surface Consistency Durability = Quality of material, environmental effect Compactibility Mobility Stability or cohesiveness Water content in concrete mix Nature of aggregate particles (shape, surface, porosity)

- 5. SPECIFICATION OF CONCRETE : Environmental effect Mixing Compacting Batching Transporting Placing Cement content Strength Water - cement ratio Aggregate - cement ratio New site •No old track record is available •Requires at least 30 test strength results of same grade of concrete Old site •Old track records is available Fly ash GGBFS TARGET MEAN STRENGTH OF CONCRETE: Methods – determined by following situation 4

- 6. Formula to calculate TARGET MEAN STRENGTH (Fm) – Fm = Fck + t X s Where, Fm = target mean strength Fck = strength of concrete ( Strength achieved in 28 days ) t = constant ( probability of no. Of results fall below Fck ) s = standard deviation ( 30 hourly test results collected & tested daily using all 24hr samples mixed together ) AGGREGATES Types -------------------------- Coarse Aggregates Particles greater than 4.75mm. E.g.- Gravel and crushed rock Downgraded Coarse Aggregates Size may be either 40mm CAN and 20mm CA1 or 30mm CAN and 15mm CA1 Fine Aggregates Particles passing through 9.5mm sieve E.g. - Natural sand 5

- 7. Properties --- 7 Physical • Texture • Structure • Composition Chemical •Solubility •Reactivity •Weathering resistance S. Properties of No. Aggregate Influence on Concrete property 1. Porosity Strength / absorption 2. Chemical stability Durability 3. Surface texture Bond grip 4. Shape, size Water demand, strength Shape of Aggregates --- Rounded gravel Irregular gravel Crushed rock

- 8. Fineness of Aggregates : Influence the water demand of concrete mix or strength. 8 Classified in 4 zones –---- Zone 1 Coarse sand Zone 2 Normal sand Zone 3 Fine sand Zone 4 Very Fine sand The selection of proportion of FA is given by Department of Environment (DOE), UK Maximum size of the Aggregates (MAS) : Mostly MAS is 10mm, 20mm or 40mm is used. For massive work, MAS is 150mm or above is used. Limitation of MAS : Minimum dimension of concrete section to be cast is < 4 X MAS Zone 1 Zone 2 Zone 3 Zone 4

- 9. Determination of Aggregate to Cement Ratio (A/C): A/C ratio can be calculated if following factors are known or determined: Shape of the aggregate Maximum aggregate size (10mm,20mm,40mm) Zone of aggregates (1,2,3,4) Degree of workability Water-to-cement ratio If concrete ingredients consist of coarse crushed and natural fine aggregates then A/C is adjusted as follows : Determine A/C for crushed aggregates for the MAS fixed for the Mix (Say Aca) Determine A/C for rounded or irregular gravel aggregates for MAS fixed for the Mix (Say Afa) Calculate A/C of the concrete mix (Say A’) as per formula A’ = Aca (%of CA1+%of CA2) + Afa (%of FA1) 100 100 Where, Aca = Actual coarse aggregate Afa = Actual fine aggregate FA1 = Fine aggregate (zone 1) CA1 = Coarse aggregate (zone 1) CA2 = Coarse aggregate (zone 2) 8

- 10. Age to strength relation – chemical compositions and fineness Higher early strength content of Tricalcium cilicate > Dicalcium cilicate Finer ground cement > coarse ground cement 10 Concrete strength are generally specified by compressive strengths and the structural design is worked out on that basis. Exact information of compressive strength of concrete depends on quality control Parameters affecting compressive strength •Cement (quality and grade) •Water (water-cement ratio) •Cement storage andtransportation •Cement packaging •Aggregates •Concrete workability •Concrete placement •Concrete compaction •Curing of concrete

- 11. Equipments Only steel or cast iron Made up of three parts 1.two side flanges 2.base plate 3.nut bolts Inside faced must be planed and machine finished All internal angles has to be accurate Edges and joints must be cleaned Surfaces should be coated by mould oil Prevent mould from rusting All parts should be bolted and then stored in close room Steel bar of 16mm dia. 600 mm length Bullet head

- 12. Process for filling & compacting cube mould must be done into three layers each app. 50mm Must be placed using scoop each layer is compacted using tamping rod needs 35 stroke for 150mm & 25 stroke for 100mm surface level should be planed No air gaps in between or scratches on surface 22

- 13. Process for identification , curing & testing On the surface level some identification mark, number and date has to be scratched and same noted on paper after removal from mould it should immediately covered with damp jute Transfer to a room having humidity90% and temperature 27^ Keep the cube in curing pond of clean water for 28 days automatic compression machine is better than manual load application Machine has a control on rate of loading, we can apply various loading while testing its strength 23

- 14. Precautions need to be taken while testing 14 allow skilled workers only Fresh water within 7 days only used for curing pond Cubes has to be deep completely Storage space has to be without any vibrations Temperature control from 22 to 30 ^c. There should not be loss in moisture while travelling from site to testing lab. Afloat should be used to push the excess concrete after pouring third layer. If the mix is too wet, allow water to drained out from mould.

- 15. Requirement of compression testing 15 machine TOP PLATEN : Harden and smooth faces Fitted on cylinder concentric with central point must be accurate Well calibrated, well certified Having capacity to crush cube Load applying rod Concrete cube placing space BOTTOM PLATEN : Plain finished Rigidly fixed on bearing block Size more than cube size Selection of machine depends on size of cube and load application

- 16. Acceptance criteria for compressive Note the reading by applying different loads from machine till the cube crashes Compressive strength should not be less than the characteristic value 26

- 17. Modes of failures USUAL FAILURES : Equal cracking on all four sides No damage to top and bottom faces Cracks are vertical zigzag pattern vertical faces breaks away leaving one pyramid between UNUSUAL FAILURES : Crushed only at one side Tensile or horizontal cracks only at one side This indicates lower compressive strength Reasons Defects in machine Faulty manual operation Faulty casting of cube Improper curing 27

- 18. Features The division and specialization of the human workforce. The use of tools, machinery, and other equipment, usually automated, in the production of standard, interchangeable parts and products. Compared to site-cast concrete, precast concrete erection is faster and less affected by adverse weather conditions. Plant casting allows increased efficiency, high quality control and greater control on finishes. 4

- 19. Comparison Site-cast no transportation the size limitation is depending on the elevation capacity only lower quality because directly affected by weather proper, large free space required Precast at plant transportation and elevation capacity limits the size- higher, industrialized quality – less affected by weather no space requirement on the site for fabrication unlimited opportunities of architectural appearance option of standardized components 5

- 20. Design concept for precast concrete buildings The design concept of the precast buildings is based on 1.build ability. 2.economy 3.standardization of precast components. 6

- 21. Precast concrete structural elements 7 Precast slabs Precast Beam & Girders

- 24. 9 Precast stairs Precast concrete Stairs Steel plates supported on 2 steel beams

- 25. Designconsiderations final position and loads transportation requirements – self load and position during transportation storing requirements – self load and position during storing – (avoid or store in the same position as it transported / built in) lifting loads – distribution of lifting points – optimal way of lifting (selection of lifting and rigging tools) vulnerable points (e.g. edges) – reduction of risk (e.g. rounded edges) 10

- 26. Types of pre cast system 1. Large-panel systems 2. Frame systems 3. Slab-column systems with walls 4. Mixed systems 11

- 27. box-like structure. both vertical and horizontal elements are load-bearing. one-story high wall panels (cross-wall system / longitudinal wall system / two way system). one-way or two way slabs. 12 1. Large-panel systems

- 28. 2. Frame systems Components are usually linear elements. The beams are seated on corbels of the pillars usually with hinged- joints (rigid connection is also an option). Joints are filled with concrete at the site. 13

- 29. 3.Lift-slab systems - partially precast in plant (pillars) / partially precast on- site (slabs). - one or more storey high pillars (max 5). - up to 30 storey high constructions. - special designed joints and temporary joints. -slabs are casted on the ground (one on top of the other) – then lifted with crane or special elevators. 14

- 30. Lift-slab procedure 15 1. pillars and the first package (e.g. 5 pieces) of slabs prepared at ground level 2. lifting boxes are mounted on the pillars + a single slab lifted to the first floor level 3-8. boxes are sequentially raised to higher positions to enable the slabs to be lifted to their required final position - slabs are held in a relative (temporary) positions by a pinning system

- 31. Equipments cranes: mobile crane tower crane (above 3stories) lifting tools: spreader beams wire rope slings rigging tools: eye bolt shakles hooks 17

- 32. Slabs: • b) Hollow Core slab- • Thicknesses of 4",6",8",10"and12" • Spansup to 40’-0" • Standard panel width =4’-0" • Typical designations =4HC6 (4=panel width infeet, HC= • Hollow Core, 6=slab thicknessininches) a) Flat slab - Standard panel width =4’-0" Thickness of 4",6"and 8" Spans up to 25’-0" Typical designations =FS4(FS=Flat Slab, 4 =thickness of slab

- 33. Beams: a) Rectangular Beam (RB)- Typical beam width =12"or16" Spans up to 50’-0" Typical designation =16RB24 (16 =width in inches, 24= depth ininches) b) "L"and "IT"(inverted "Tee") beams (LBand IT)- Typically used tosupport slabs, walls, masonry, and beams Typical beam width=12" Depths of 20",28",36",44",52"and 60"

- 36. c) Double Tee Beam (DT) - Combination beam and slab Spans up to 100’-0" Typical width=8’-0" Depths of 12", 18", 24" and 32" Designation =8DT24+2 (8 =width in feet, 24 = depth, +2=2"topping)

- 37. d) Single Tee Beam (ST)- Combination beam and slab Spans up to 120’-0" Typical width =8’-0" Typical depths of 36"and 48" Designation =8ST36+2(8 =width in feet, 24 =depth, +2= 2" topping)

- 38. Walls Wall panels available in standard 8’-0" widths. Can be flat, or have architectural features such as window and door openings, ribs, reveals, textures, sandwich (insulation built-in), sculptured,etc.

- 40. Assembling…. 18 Column to column connection

- 41. Beam to column connection 19

- 43. 21 Precast concrete structure consisting of solid wall panels and hollow core slabs. Wall to slab connection

- 44. Methods of Attachment of PrecastConcrete Members:

- 45. Weld Plates Themostcommon method of attachment of precast members isby use of steelweld plates. Typically, the precast members have embedded plates that can be used as weldingsurfacesforlooseconnecting plates orangles (seebelow):

- 46. Rebar andGrout Used typically withslabs,reinforcing barsare splicedintoslabsand grouted inplace (see below):

- 48. Precast Concrete Slabs • Used for floor and roof decks. • Deeper elements (toward the right below) span further than those that are shallower (toward the left). • Right: Hollow core slabs stacked at the precasting plant.

- 49. Precast Concrete Beams and Girders • Provide support for slabs. • The projecting reinforcing bars will bond with concrete cast on site. • Right: Inverted tee beams supported by precast columns. M

- 50. Precast Concrete Columns and Wall Panels Provide support for beam and slab elements. •Since these elements carry mainly axial loads with little bending force, they may be conventionally reinforced without prestressing. •Or, long, slender multistory elements may be prestressed to provide resistance to bending forces during handling and erection (columns at right). LEM

- 51. Precast Concrete Columns and Wall Panels • Precast concrete wall panels may be solid (right), hollow, or sandwiched (with an insulating core). • Wall panels can be ribbed, to increase their vertical span capacity while minimizing weight, or formed into other special shapes (below).

- 52. Other Precast Concrete Elements • Precast concrete stairs (below) •Uniquely shaped structural elements for a sports stadium (right) PRECAST, PRESTRESSED CONCRETE STRUCTURAL ELEM

- 53. Assembly Concepts for Precast Concrete Buildings Vertical support can be provided by precast columns and beams (above), wall panels (below), or a combination of all three. •The choice of roof and floor slab elements depends mainly on span requirements. •Precast slab elements are frequently also used with other vertical loadbearing systems such as sitecast concrete, reinforced masonry, or steel. ELEM

- 54. Assembly Concepts for Precast Concrete Buildings •Above: Precast concrete structure consisting of solid wall panels and hollow core slabs. •Below: A single story warehouse consisting of double tees supported by insulated sandwich wall panels.

- 55. Assembly Concepts for Precast Concrete Buildings •A parking garage structure consisting of precast double tees supported by inverted tee beams on haunches columns.

- 56. are manufactured in casting beds, 800 ft or more in length. •High-strength steel strands are strung the length of the bed and tensioned. •Conventional reinforcing, weld plates, blockouts, lifting loops, and other embedded items are added as needed. •Concrete is placed. Casting Hollow Core Planks •Precast elements Untensioned prestressing strands can be seen in the left- most casting bed. In the bed second from the right, low- slump concrete for hollow core slabs is being formed over tensioned strands using an extrusion process. A completed hollow core casting is visible at the far right.

- 57. Prestressing and Reinforcing Steel •Many precast elements contain both prestressing strands and conventional reinforcing. •Right: The prestressing strands for an AASHTO girder are depressed into a shallow v- shape to most efficiently resist tensile forces in the beam. Shear stirrups are formed from conventional steel reinforcing.

- 58. Casting Hollow Core Planks •Once the concrete has cured to sufficient strength, the castings are cut into sections of desired length (above). •In some cases, transverse bulkheads are inserted to divide the casting bed into sections before concrete is placed. In this case, only the prestressing strands need to be cut to separate the sections (below).

- 59. Casting Hollow Core Planks • Individual sections are lifted from the casting bed (right) and stockpiled to await shipping to the construction site.

- 60. Casting Hollow Core Planks • Precast concrete elements are shipped to the construction site by truck and erected on site by crane.

- 61. Casting Hollow CorePlanks •Sample hollow core slab sections of varying depths. •At bottom left, note the insulated sandwich floor panel.

- 62. Advantages Of precast concrete construction Quick erection times Possibility of conversion, disassembling and moving to another site Possibility of erection in areas where a traditional construction practice is not possible or difficult Low labor intensivity Reduce wastage of materials Easier management of construction sites Better overall construction quality Ideal fit for simple and complex structures 22

- 63. Disadvantages ofPrecast Concrete Construction Somewhat limited building design flexibility Very heavy members Camber in beams and slabs Very small margin forerror Connections may be difficult Because panel size is limited, precast concrete can not be used for two-way structural systems. Economics of scale demand regularly shaped buildings. Need for repetition of forms will affect building design. Joints between panels are oftenexpensive and complicated. Skilled workmanship is required in the application of the panel on site. Cranes are required tolift panels.

- 64. Limitations size of the units. location of window openings has a limited variety. joint details are predefined. site access and storage capacity. require high quality control. enable interaction between design phase and production planning. difficult to handling & transporting. 23

- 65. Popular UsesofPrecast Concrete Concrete curtain walls As an exterior cladding(may include exposed aggregate) For structural walls Ability to precast in threedimensions allows precast panels to form parts of mechanical systems

- 66. Scheduling some approximate data for installation emplacement of hollow core floor slabs - 300 m2/day erection of pillars/columns - 8 pieces/day emplacement of beams - 15 pieces/day emplacement of double tee slabs - 25 pieces/day emplacement of walls - 15 pieces/day construction of stair and elevator shafts - 2 floors/day 24

- 67. Examples…. 25 The hospital will feature multi-trade prefabricated racks in the corridors, an approach that is still new in the U.S.

- 68. 26 Miami Valley Hospital Dayton,OH

- 69. Conclusion 27 oThe use of prefabrication and preassembly is estimated to have almost doubled in the last 15 years, increasing by 86%. oThe use of precast concrete construction can significantly reduce the amount of construction waste generated on construction sites. o Reduce adverse environmental impact on sites. o Enhance quality control of concreting work. o Reduce the amount of site labour. o Increase worker safety . o Other impediments to prefabrication and preassembly are increased transportation difficulties, greater inflexibility, and more advanced procurement requirements.

- 70. 1) Jenil 2) Nalin 3) Sid 4) Riyan 5) Nithin