JD3_MS_Corrosion_Coupon_Analysis (10Dec15 to 24Jan16)

•

2 likes•198 views

Report

Share

Report

Share

Download to read offline

Recommended

More Related Content

What's hot

What's hot (10)

Heat engine thermodynamics for basic mechanical engineering

Heat engine thermodynamics for basic mechanical engineering

Lecture 18 second law of thermodynamics. carnot's cycle

Lecture 18 second law of thermodynamics. carnot's cycle

Viewers also liked

Viewers also liked (8)

An Aid to Support Root-Cause Investigation - Internal Corrosion Pipeline Failure

An Aid to Support Root-Cause Investigation - Internal Corrosion Pipeline Failure

AIC Corrosion Coupon Paper, 1995 (Coupon6.Txt With Graphs)

AIC Corrosion Coupon Paper, 1995 (Coupon6.Txt With Graphs)

JD3_MS_Corrosion_Coupon_Analysis (10Dec15 to 24Jan16)

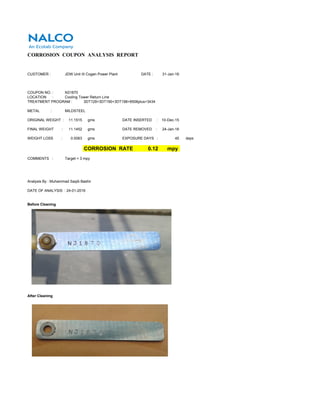

- 1. CORROSION COUPON ANALYSIS REPORT CUSTOMER : JDW Unit III Cogen Power Plant DATE : 31-Jan-16 COUPON NO. : N31870 LOCATION : Cooling Tower Return Line TREATMENT PROGRAM : 3DT129+3DT190+3DT198+8506plus+3434 METAL : MILDSTEEL ORIGINAL WEIGHT : 11.1515 gms DATE INSERTED : 10-Dec-15 FINAL WEIGHT : 11.1452 gms DATE REMOVED : 24-Jan-16 WEIGHT LOSS : 0.0063 gms EXPOSURE DAYS : 45 days CORROSION RATE : 0.12 mpy COMMENTS : Target < 3 mpy Analysis By : Muhammad Saqib Bashir DATE OF ANALYSIS : 24-01-2016 Before Cleaning After Cleaning