Batch, Fed-Batch, Continuous Cultivation

- 2. BATCH CULTIVATION CONTINUOUS CULTIVATION 1. The bacteria are inoculated into the bioreactor (always stirred tank bioreactor). 2. Then, under certain conditions (temperature, pH, aeration, etc.) the bacteria go through all the growth phases (lag, exponential, stationary). 1. The fresh medium flows into the fermentor continuously, and part of the medium in the reactor is withdrawn from the fermenter at the same flow rate of the inlet flow. 2. The bacteria is grown under certain conditions (temperature, pH, aeration) Advantages: • can be used for diff reactions every day. • Safe: can be properly sterilized. • Little risk of infection or strain mutation • Complete conversion of substrate is possible Advantages: • Works all the time: low labor cost, good utilization of reactor • Often efficient: due to the autocatalytic nature of microbial reactions,. • the productivity can be high. • Automation may be very appealing. • Constant product quality Dis-advantages: •High labor cost •Much idle time – Sterilization, growth, cleaning •Safety – filling emptying, cleaning. Dis-advantages: •promised continuous production for months fails due to a. infection. b. spontaneous mutation of microorganisms to non producing strain

- 3. Batch cultivation is closed system whereBatch cultivation is closed system where there is no interaction between the systemthere is no interaction between the system and the surrounding during the process.and the surrounding during the process. Except air during the aerobic cultivation.Except air during the aerobic cultivation. In Batch cultivation we prepare medium,In Batch cultivation we prepare medium, sterilize it and inoculate the culture into thesterilize it and inoculate the culture into the bioreactor.bioreactor. Allow the cells to grow and produce theAllow the cells to grow and produce the product.product. Once the product formation reachesOnce the product formation reaches maximum harvest the fermentation broth.maximum harvest the fermentation broth.

- 4. How cells grow duringHow cells grow during Batch cultivationBatch cultivation After inoculating the medium and startAfter inoculating the medium and start measuring the biomass at different timemeasuring the biomass at different time intervals, you may find six different phases.intervals, you may find six different phases. They areThey are 1.1. Lag phaseLag phase 2.2. Accelerated growth phaseAccelerated growth phase 3.3. Exponential growth phaseExponential growth phase 4.4. Decelerated growth phaseDecelerated growth phase 5.5. Stationary phaseStationary phase 6.6. Death phaseDeath phase

- 5. Ln X X µ

- 6. Lag PhaseLag Phase Lag Phase is an initial period of cultivation duringLag Phase is an initial period of cultivation during which the change of cell number is zero or negligible.which the change of cell number is zero or negligible. Eventhough the cell number doesnot increase, theEventhough the cell number doesnot increase, the cells may grow in size during this period.cells may grow in size during this period. The Lag phase results from several factors.The Lag phase results from several factors. When cells are placed in the fresh medium, theWhen cells are placed in the fresh medium, the intracellular concentrations of cofactors, amino acids,intracellular concentrations of cofactors, amino acids, ions will decrease and these have to be synthesized /ions will decrease and these have to be synthesized / transported first before cell division to occur.transported first before cell division to occur. When the cells are inoculated into medium containingWhen the cells are inoculated into medium containing different carbon source then the enzymes for itsdifferent carbon source then the enzymes for its metabolism have to be transported.metabolism have to be transported.

- 7. When cell are placed in medium containingWhen cell are placed in medium containing several carbon sources then several lag phasesseveral carbon sources then several lag phases may result. This is known as diauxic growth. Whenmay result. This is known as diauxic growth. When glucose and lactose are present then glucose willglucose and lactose are present then glucose will be utilized first then lactose. Presence of glucosebe utilized first then lactose. Presence of glucose will have catabolite repression on galactosidasewill have catabolite repression on galactosidase enzyme which is required for lactose utilizationenzyme which is required for lactose utilization

- 8. How to avoid lag phaseHow to avoid lag phase Lag phase is non productive period in theLag phase is non productive period in the industrial fermentations. Henceindustrial fermentations. Hence minimizing it is essential.minimizing it is essential. The stage of culture from where theThe stage of culture from where the inoculum is drawn is important.inoculum is drawn is important. Exponentially growing cells will haveExponentially growing cells will have adequate concentrations of intermediatesadequate concentrations of intermediates and intracellular pool of compounds.and intracellular pool of compounds. Hence if the inoculum is drawn from thisHence if the inoculum is drawn from this stage they will not suffer dilution effect.stage they will not suffer dilution effect.

- 9. Size of the inoculum – If the size of theSize of the inoculum – If the size of the inoculum is large then the lag phase caninoculum is large then the lag phase can be minimized. Generally 10% are used forbe minimized. Generally 10% are used for yeast and mold and 5% for bacteria.yeast and mold and 5% for bacteria. Medium of inoculum should be same ofMedium of inoculum should be same of that production medium.that production medium. In certain cases such as recombinantIn certain cases such as recombinant E.coliE.coli cultivation to minimize plasmid losscultivation to minimize plasmid loss higher percentage of inoculum will behigher percentage of inoculum will be used.used.

- 10. Accelerated growth phaseAccelerated growth phase At the end of LagAt the end of Lag phase, when growthphase, when growth begins the divisionbegins the division rate increaserate increase gradually and reachesgradually and reaches a maximum value.a maximum value. The sp growth rateThe sp growth rate increases toincreases to maximum during thismaximum during this phase.phase.

- 11. Exponential growth phaseExponential growth phase Cell division occurs in this phase.Cell division occurs in this phase. Often cell dry weight is used for cellOften cell dry weight is used for cell concentration. During exponential phase we writeconcentration. During exponential phase we write asas Where µ - Specific growth rateWhere µ - Specific growth rate X- cell dry weightX- cell dry weight X dt dX µ=

- 12. Rearranging and integrating the eqnRearranging and integrating the eqn mµ 2ln= = = = = ∫∫ d μt o o t 0 X Xo t 0 X Xo t eXX μt X Xln tμlnX dtμ X dX

- 13. Sometimes the doubling times for cellSometimes the doubling times for cell number and cell dry weight may differ asnumber and cell dry weight may differ as a result of non constant cell mass pera result of non constant cell mass per cell.cell. If the growth rates calculated based onIf the growth rates calculated based on these are equal then the growth is saidthese are equal then the growth is said to be balanced growth. In the balancedto be balanced growth. In the balanced growth the composition of the cell isgrowth the composition of the cell is equal. Balanced growth will occur whenequal. Balanced growth will occur when adequate supply of all nutrients is thereadequate supply of all nutrients is there and no toxic by products are generated.and no toxic by products are generated. In unbalanced growth the cell compositionIn unbalanced growth the cell composition varies (eg. Protein content) etc.,varies (eg. Protein content) etc.,

- 14. Other phases of growthOther phases of growth The end of the exponential phase occur whenThe end of the exponential phase occur when any of the essential nutrients is depleted or toxicany of the essential nutrients is depleted or toxic metabolite accumulated in the system. Duringmetabolite accumulated in the system. During this phase the growth rate declines.this phase the growth rate declines. Stationary phase will follow this phase. TheStationary phase will follow this phase. The length of stationary phase may vary with celllength of stationary phase may vary with cell type, previous growth conditions etc., In certaintype, previous growth conditions etc., In certain cases the product formation will occur during thiscases the product formation will occur during this phasephase Following this is the death phase where the cellsFollowing this is the death phase where the cells will start to lyse and the cell density decreases.will start to lyse and the cell density decreases.

- 15. Environmental conditions affectingEnvironmental conditions affecting cell growthcell growth Substrate concentrationSubstrate concentration TemperatureTemperature pHpH Dissolved oxygenDissolved oxygen OthersOthers

- 16. Substrate concentrationSubstrate concentration The effect of substrate concentration on theThe effect of substrate concentration on the Specific growth rate is represented bySpecific growth rate is represented by monod equationmonod equation µ - Specific growth rateµ - Specific growth rate µµmaxmax – Maximum specific growth rate– Maximum specific growth rate S – Residual substrate concentrationS – Residual substrate concentration KKss- Substrate saturation constant- Substrate saturation constant SK S μμ s max + =

- 17. When S>>KsWhen S>>Ks µ = µµ = µmaxmax When S=KsWhen S=Ks µ = µµ = µmaxmax/2/2 Thus the saturation constant Ks isThus the saturation constant Ks is numerically equivalent to the substratenumerically equivalent to the substrate concentration when its growth rate is halfconcentration when its growth rate is half the maximum.the maximum.

- 18. Effect of TemperatureEffect of Temperature Temperature is an important factor affectingTemperature is an important factor affecting growth of cells. According to temperature optimagrowth of cells. According to temperature optima of the growth the cells can be classified intoof the growth the cells can be classified into three groupsthree groups Psychrophiles < 20Psychrophiles < 2000 CC Mesophiles – 20-50Mesophiles – 20-50oo CC Thermophiles > 50Thermophiles > 5000 CC

- 19. Above or below the optimumAbove or below the optimum temperature range thetemperature range the growth rate decreases.growth rate decreases. Temperature growth rateTemperature growth rate relationship is explained byrelationship is explained by arrhenius equationarrhenius equation µ = A eµ = A e-E/RT-E/RT Temperature also affects theTemperature also affects the product formation.product formation. Temperature may also affectTemperature may also affect the rate limiting step eg. atthe rate limiting step eg. at higher temperatureshigher temperatures diffusion may become ratediffusion may become rate limitinglimiting

- 20. Effect of pHEffect of pH Hydrogen ion concentration affects theHydrogen ion concentration affects the activity of enzymes and therefore theactivity of enzymes and therefore the microbial growth rate.microbial growth rate. The optimal pH for growth and productThe optimal pH for growth and product formation may be different eg. Citric acidformation may be different eg. Citric acid fermentation.fermentation. pH optimum for growth ofpH optimum for growth of Bacteria – 3 to 8; Yeast – 3 to 6; Molds – 3 toBacteria – 3 to 8; Yeast – 3 to 6; Molds – 3 to 77 Plant cells – 5 to 6; Animal cells – 6.5 to 7.5Plant cells – 5 to 6; Animal cells – 6.5 to 7.5

- 21. Many organisms have mechanismMany organisms have mechanism to maintain intracellular pH at ato maintain intracellular pH at a relatively constant level in therelatively constant level in the presence of fluctuations inpresence of fluctuations in environmental pH.environmental pH. When pH differs from optimal valueWhen pH differs from optimal value the maintenance energythe maintenance energy requirement increases.requirement increases. In most fermentations pH can varyIn most fermentations pH can vary substantially. Often the nature ofsubstantially. Often the nature of nitrogen source can be important.nitrogen source can be important.

- 23. Dissolved oxygen concentrationDissolved oxygen concentration Dissolved oxygen concentration is an importantDissolved oxygen concentration is an important substrate in aerobic concentration and may besubstrate in aerobic concentration and may be limiting in certain cases.limiting in certain cases. Oxygen is sparingly soluble in water and theOxygen is sparingly soluble in water and the cells will uptake oxygen from the medium only.cells will uptake oxygen from the medium only. The growth of microorganisms will be dependantThe growth of microorganisms will be dependant on dissolved oxygen concentration upto certainon dissolved oxygen concentration upto certain concentration known as critical oxygenconcentration known as critical oxygen concentration and above which the growth willconcentration and above which the growth will not be dependant on the DO concentration.not be dependant on the DO concentration.

- 24. DO concentration should be above 20 % forDO concentration should be above 20 % for bacteria and yeast and it is 40% for moldsbacteria and yeast and it is 40% for molds depending on the size.depending on the size. DODO µµ Critical DO concentration

- 25. Redox potentialRedox potential Ionic concentrationsIonic concentrations Dissolved Carbondioxide concentrationDissolved Carbondioxide concentration Other factorsOther factors

- 27. Luedeking–Piret ModelLuedeking–Piret Model Growth-associated products are producedGrowth-associated products are produced simultaneously with microbial growth. Thesimultaneously with microbial growth. The specific rate of product formation is proportionalspecific rate of product formation is proportional to the specific growth rate µto the specific growth rate µgg Eg: production of a constitutive enzymeEg: production of a constitutive enzyme Nongrowth-associated product formation: @Nongrowth-associated product formation: @ stationary phase when growth rate is zero. Thestationary phase when growth rate is zero. The specific rate of product formation is constant.specific rate of product formation is constant. Eg: antibioticsEg: antibiotics Mixed: takes place during slow growth and inMixed: takes place during slow growth and in stationary phases.stationary phases. Eg: Lactic acid fermentation, xantham gumEg: Lactic acid fermentation, xantham gum

- 28. Product formation for growth associatedProduct formation for growth associated Product formation for mixed growth associatedProduct formation for mixed growth associated Product formation for non growth associatedProduct formation for non growth associated µXPp Y dt dP X q / 1 == tconsqp tan== β βαµ +=pq

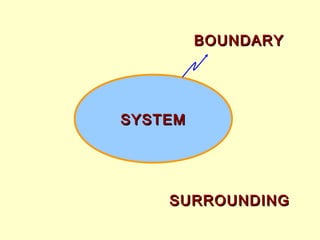

- 30. Continuous cultivationContinuous cultivation SYSTEMSYSTEM SURROUNDINGSURROUNDING BOUNDARYBOUNDARY Open systemOpen system

- 35. Steady state : steady state is the condition atSteady state : steady state is the condition at which there is no change in the concentrationswhich there is no change in the concentrations of biomass, substrate, product or anythingof biomass, substrate, product or anything How will you say that the culture has attainedHow will you say that the culture has attained steady statesteady state When there is no change for two volumeWhen there is no change for two volume change of medium then the culture is assumedchange of medium then the culture is assumed to be in steady stateto be in steady state What is meant by dilution rateWhat is meant by dilution rate Dilution rate is the ratio of feed rate to workingDilution rate is the ratio of feed rate to working volumevolume

- 36. x-D diagram is the plot of dilution rate Vsx-D diagram is the plot of dilution rate Vs steady state biomass concentration at thatsteady state biomass concentration at that dilution rate.dilution rate. Productivity in continuous cultivation is theProductivity in continuous cultivation is the product of dilution rate with steady stateproduct of dilution rate with steady state biomass at that dilution rate.biomass at that dilution rate. Upto what dilution rate you can run theUpto what dilution rate you can run the continuous cultivation?continuous cultivation? In continuous cultivation the dilution rate will beIn continuous cultivation the dilution rate will be equal to the growth rate of the microorganism.equal to the growth rate of the microorganism. You can increase the dilution rate to the max.You can increase the dilution rate to the max. growth rate of the organism. Beyond whichgrowth rate of the organism. Beyond which washout will occurwashout will occur

- 37. Medium optimization by continuousMedium optimization by continuous cultivationcultivation First construct x-D diagramFirst construct x-D diagram Pulse various compounds to the mediumPulse various compounds to the medium during steady state and identify theduring steady state and identify the positive nutrients.positive nutrients. Shift the inlet medium with positiveShift the inlet medium with positive nutrients.nutrients. Continue this process till you haveContinue this process till you have completed with all the positive nutrientscompleted with all the positive nutrients Final x-D diagram and evaluate kineticFinal x-D diagram and evaluate kinetic constantsconstants

- 38. Productivity in batch and continuousProductivity in batch and continuous Batch cultivationBatch cultivation Continuous cultivationContinuous cultivation batch o S X turn om b t SY P t X X ln μ 1 t = + = oSXm SYμP DXP = = turnm o turnm o oSXm oSXm t X X t X X SY SY Batch Chemostat µ µ µ µ += + = ln ln

- 39. Secondary metabolites are produced onlySecondary metabolites are produced only during the stationary phase. Hence theduring the stationary phase. Hence the continuous cultivation is not suitable forcontinuous cultivation is not suitable for them.them. Maintenance of sterility is very difficult.Maintenance of sterility is very difficult. High infrastructure cost is required.High infrastructure cost is required. Why continuous cultivation is notWhy continuous cultivation is not used in the industriesused in the industries

- 40. Fed Batch cultivationFed Batch cultivation Batch cultivation have low productivityBatch cultivation have low productivity Though continuous cultivationThough continuous cultivation productivity is higher it cannot be usedproductivity is higher it cannot be used for secondary metabolitesfor secondary metabolites Fed batch cultivation is semi openFed batch cultivation is semi open systemsystem Here nutrients are fed slowly intoHere nutrients are fed slowly into medium either continuously ormedium either continuously or discontinuously in stages.discontinuously in stages.