05 gears part 2 (1) (1) (1)

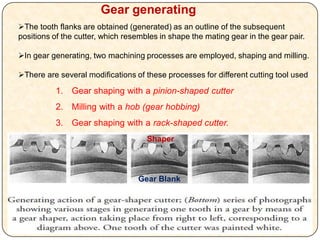

- 1. Gear generating The tooth flanks are obtained (generated) as an outline of the subsequent positions of the cutter, which resembles in shape the mating gear in the gear pair. In gear generating, two machining processes are employed, shaping and milling. There are several modifications of these processes for different cutting tool used 1. Gear shaping with a pinion-shaped cutter 2. Milling with a hob (gear hobbing) 3. Gear shaping with a rack-shaped cutter. Gear Blank Shaper

- 2. Gear Shaping Gear shaping process is defined as a process for generating gear teeth by a rotating and reciprocating pinion-shaped cutter. It is a true shape-generation process in which the gear-shaped tool cuts itself into mesh with the gear blank. The cutter axis is parallel to the gear axis and cutting may take place either at the down-stroke or upstroke of the machine. A train of gears provides the required relative motion between the cutter shaft and the gear-blank shaft. Gear shaping is one of the most versatile of all gear cutting operations used to produce internal gears, external gears, and integral gear-pinion arrangements. Advantages of gear shaping with pinion-shaped cutter are the high dimensional accuracy achieved and the not too expensive tool. The process is applied for finishing operation in all types of production rates. But any errors in one tooth of the shaper cutter will be directly transferred to the gear.

- 4. Gear Hobbing Gear hobbing is a machining process in which gear teeth are progressively generated by a series of cuts with a helical cutting tool (hob). All motions in hobbing are rotary, and the hob and gear blank rotate continuously as in two gears meshing until all teeth are cut. When hobbing a spur gear, the angle between the hob and gear blank axes is 90° minus the lead angle at the hob threads. For helical gears, the hob is set so that the helix angle of the hob is parallel with the tooth direction of the gear being cut. Additional movement along the tooth length is necessary in order to cut the whole tooth length

- 5. The cutting of a gear by means of a hob is a continuous operation. The hob and the gear blank are connected by a proper gearing so that they rotate in mesh. To start cutting a gear, the rotating hob is fed inward until the proper setting for tooth depth is achieved, then cutting continues until the entire gear is finished. Machines for cutting precise gears are generally CNC-type and often are housed in temperature controlled rooms to avoid dimensional deformations. The gear hob is a formed tooth milling cutter with helical teeth arranged like the thread on a screw. No repositioning of tool or blank is required and each tooth is cut by multiple hob-teeth, averaging out any tool errors. Excellent surface finish is achieved by this method and it is widely used for production of gears.

- 6. Shaping with a Rack-Shaped Cutter In the gear shaping with a rack-shaped cutter, gear teeth are generated by a cutting tool called a rack shaper. The hardened and sharpened rack is reciprocated along the axis of the gear blank and fed into it while gear blank is being rotated so as to generate the involute tooth on the gear blank. RACK Blank The rack shaper is actually a segment of a rack. Because it is not practical to have more than 6-12 teeth on a rack cutter, the cutter must be disengaged at suitable intervals and returned to the starting point, the gear blank meanwhile remaining fixed. Advantages of this method involve a very high dimensional accuracy and cheap cutting tool (the rack shaper’s teeth blanks are straight, which makes sharpening of the tool easy). The process can be used for low-quantity as well as high-quantity production of spur and helix external gears.

- 7. Broaching Broaching can also be used to produce gear teeth and is particularly applicable to internal teeth. The process is rapid and produces fine surface finish with high dimensional accuracy. However, because broaches are expensive-and a separate broach is required for each size of gear-this method is suitable mainly for high-quantity production.

- 8. Finishing Processes As produced by any of the process described, the surface finish and dimensional accuracy may not be accurate enough for certain applications. Poor surface finish results in lot of noise, excessive wear, play or backlash even leads to failure of tooth. To overcome the defects finishing is necessary for smooth running of gears. Finishing operations typically removes little or no material but improves dimensional accuracy, surface finish. The various finishing processes are : Gear Shaving Gear Grinding Gear Burnishing Gear Lapping Gear honing

- 9. Gear Shaving Shaving is similar to gear shaping in this gear is rotated at high speed in mesh with a gear shaving tool which is in the form of a rack or pinion and also reciprocated simultaneously. The teeth of shaving tool are hardened accurately ground an their faces are provided with serrations. Serrations form the cutting edges and will perform scraping operation on the mating faces of the gear teeth to be finished. Shaving with rack type tool is used for small gears. Serrations

- 10. Gear Grinding Gears required to operate on high speeds an carry heavy loads are always hardened, which naturally implies a small distortion on the teeth flanks. In order to remove distortion and have accurate profiles on the teeth for smooth running, grinding is essential. Grinding is used to correct the heat-treatment distortion in gears hardened after roughing. Improvement in surface finish and error correction of earlier machining are added advantages. Two common methods used for grinding hardened gear teeth are forming and generating. In forming process the abrasive wheel is first trued to the required shape and size of gear teeth. The work is mounted between centers on an indexing head. In generating process grinding is done by flat faces of grinding wheel.

- 11. With a small amount of metal removal high surface finish is obtained. Gear forming Gear generating

- 12. Gear Burnishing In burnishing, a specially hardened gear is run over rough machined gear. The high forces at the tooth interface cause plastic yielding of the gear tooth surface which improves finish and work hardens the surface creating beneficial compressive residual stresses. Gear Lapping and Honing: Lapping and honing both employ an abrasive-impregnated gear or gear-shaped tool that is run against the gear to abrade the surface. In both cases, the abrasive tool drives the gear in what amounts to an accelerated and controlled run-in to improve surface finish and the accuracy. Lapping