Manufacturing and Quality Control of Cement.

- 1. 2015 Abhishek Garai, M.Sc Chemistry NIT Rourkela, Orissa. OCL India Ltd. 5/2/2015 Cement Manufacturing & Quality Control

- 2. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 1 ACKNOWLEDGEMENT I wish to express my profound gratitude to the management of OCL India limited for providing me this golden opportunity to do this Industrial training in the Cement plant Rajgangpur. I also express my sincere gratitude to Mr. Chandan Sengupta, Sr. Manager of Quality Assurance department of OCL for his guidance in learning and help me to make this project beside of his busy life. I am also grateful to Mr Ashraf Khan, Mr Subhasis Dash sir indispensable help for clarifying my various doubts with their lucid and elaborate explanation .The co-operation of Mr Sashi Bhusan Singh , Mr S K Barik and all other personnel in physical ,chemical laboratories are also highly appreciated. I am also indebted to the staff at the Central Control Room (CCR) for explaining me the whole cement manufacturing process and various control and operational aspects of process. Thanking You Rajgangpur.

- 3. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 2 SCOPE This report gives the descriptions of cement manufacturing process and the chemical and physical quality determination of Cement at OCL, that I have learned during the period of my training. While emphasizing the application of the Chemistry I dealt with Chemical analysis (Gravimetric & EDTA analysis ), XRF-analysis , XRD-analysis and test for physical properties determination i,e NC, Setting Time, Compressive Strength, Fineness, Soundness, etc. The major unit operations encountered during cement production are size material transport, grinding and dust separation in ESP and Bag filters the unit processing involved are dehydrations, de-carbonation and clinkerization. Hot exit gases from the kiln are circulated to different units for better heat economy. Materials balance is used in the raw mix design. Quality control is essential for producing that meets the desired quality of cement. While I have taken every effort to keep this report free of errors, any suggestions are welcomed.

- 4. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 3 Contents Fuel Analysis. Reactions during Processing. Cement Chemistry. Waste Utilization. Problem. Conclusion. Biblography. Introduction Profile of OCL History Varieties of Cement,Properties and their diffrent applications. Raw materials & Handling of Raw materials. Production Process Quality Control & Assurence Procedure. * Various Technique Used for analysis and their prinnciple of Operation.

- 5. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 4 Cement is an inorganic, non-metallic substance with hydraulic binding properties, and is used as a binding agent in building materials. It is a fine powder, usually grey in colour that consists of a mixture of the hydraulic cement minerals to which one or more forms of calcium sulphate have been added. Mixed with water it forms a paste, which hardens due to formation of cement mineral hydrates. Cement is the binding agent in concrete, which is a combination of cement, mineral aggregates and water. Concrete is a key building material for a variety of applications. The cement industries first grind the raw materials then make clinker in rotary kiln by firing coal and feeding grind raw materials with proper raw mix design. Then the clicker is grinded again and made cement with mixing various additives and gypsum. Clinker is produced through a controlled high-temperature burn in a kiln of a measured blend of calcareous rocks (usually limestone) and lesser quantities of siliceous, aluminous, and ferrous materials. The kiln feed blend (also called raw meal or raw mix) is adjusted depending on the chemical composition of the raw materials and the type of cement desired. Portland cement is the major cement product in India. Although other cements are also made for very minor amount. Cement plants are typically constructed in areas with substantial raw materials deposits (e.g. 50 years or longer).There are almost 207 cement manufacturing plant in INDIA in 2014 spread all over India. Total 71 companies are now present in India for cement among them ‘UltraTech’ has the highest no of plant that is 22.Then ‘Jaypee Cement’, ‘ACC cement’ take their position with 20 & 17 no of plant respectively.

- 6. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 5 Type Private Industry Cement Manufacturing. Founded 1949 Founder/Co- Founder Sjt. Jaidayal Dalmia Managing Director Sjt. Puneet Dalmia CEO Sjt. Mahendra Singhi Executive Director DD ATAL Head Office 4 Scindia House, Connaught Palace, New Delhi Cement Manufacturing Capacity 4.0 Million TPA at Rajgangpur Products OPC-43,OPC-53,OPC-53 S PSC, PPC, SRPC, Masonry Cement. Contacts www.ocl.in ocl_cement@ocl.in, ocl_rajgangpur@ocl.in

- 7. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 6 In 1950-51 at the request of Government of Odisha to manufacture of super grade cement in the construction of Hirakud Dam ,Sit.Jaidayalji Dalmia an Industrialist farsighted his vision to set up a cement manufacturing plant at Rajgangpur with the supply of main raw materials from Langiberna . The origin of OCL was seeded in the time that signalled India's independence. A dream unleashed. A blue print of growth was drawn. Endeavours to reconstruct economy set in. Indian industry woke up to the key challenge of self-reliance. Agriculture took a turn to modernity with construction of dams across the country. Against such a bubbling background Sjt. Jaidayalji Dalmia, an industrialist of farsighted vision set up a cement plant at Rajgangpur during 1950-51 at the request of Government of Odisha to manufacture super grade cement for use in the construction of Hirakud dam. The plant that went on steam as Orissa cement limited during 1952 transformed itself into OCL India Limited during 1996 to better reflect its multifarious activities. Period Achievements 1949 Company got incorporated. 1951 Cement manufacturing started with a 500 TPD Wet process plant. 1988 Conversion from Wet to Dry process with capacity enhancement to 5.25 Lakh TPA. 1997 First in India to install Vertical Roller Mill for cement grinding (CVRM) and enhancing the cement manufacturing capacity to 10 Lakh TPA. 1998 Obtained ISO 9002 Certification. 2003 The first Cement manufacturer in eastern India granted with the right to use American Petroleum Institutes (API) monogram for its OIL Well Cement. 2004 Obtained ISO 9001-2000 Certification. 2005 3rd CVRM installed. 2009 2nd line Clinkerisation unit commissioned with installed capacity of 17 lakh TPA. 2009 Project activities commenced for Captive Thermal Plant 2 X 27 MW capacity.

- 8. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 7 2009 Bagged National Award for Energy efficiency in Cement Industry from NCCBM. 2010 Obtained ISO 9001-2008 Certification. 2010 Obtained Certification for Environment Management System as per IS/ISO 14001:2004 and Occupational Health and safety Management System as per IS/ISO 18001:2007 from BIS. From a modest 500 TPD capacity imported single wet process Kiln of FL Smidth make of Denmark, the house of 'Konark' brand cement has journeyed a long way. To cater the growing demand the company enhanced its installed capacity with addition of its second wet process 600 TPD kiln in 1957.Keeping a steady progress with time and technology, OCL has produced the first clinker through modernized and fully Automated dry process plant in 1988 and further enhanced its installed capacity by adding its 2nd clinkerization unit in 2009. In the early fifties OCL has installed four numbers of Ball mills of FL Smidth for cement grinding purpose. Later on, to keep pace with the technological advancement and facilitating manufacture of blended cement, three giant Vertical Roller Mills with combined and separate grinding systems were installed during the period of 1997 to 2005. To ensure easy availability and timely supply of cement to the customers in the coastal area of Odisha, a split level cement grinding unit Kapilas Cement Works was set up near Cuttack in 2008. The urge to modernize and continuously upgrade technology has gone beyond the plant and transformed OCL's limestone mines into one of totally mechanized operations from the earlier system of manual mining. The drive for excellence through continuous technological up-gradation has resulted in many 'Firsts' for OCL. A few of them are, The first auto kiln control system based on fuzzy logic in India, The world's largest cement and slag grinding Vertical Roller Mill during 1997,The second such Cement Vertical Roller Mill during 2001, The third Cement Vertical Roller Mill again with 60% additional capacity and first in the world market in 2005. The target centric investments in R&D and application specific product development have both enabled OCL to enlarge and include in its product range various grades of Ordinary Portland Cement (OPC) like 43 and 53 grades; 53S Grade cement for use in the manufacture of railway sleepers;

- 9. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 8 Portland Slag Cement (PSC); Fly Ash based Portland Pozzolana Cement (PPC), Sulphate Resisting Portland Cement (SRPC); Masonry Cement. For a brief spell OCL also ventured into manufacture of a wide range of cement allied products including spun pipes etc., in early sixties of the last millennium and became a prime source of high strength reinforced spun pipes and pre-stressed concrete poles. It was the first manufacturer of pre- stressed concrete railway sleepers. Decades later, the company still reigns supreme as a supplier of railway sleeper grade cement in India. Industrial Research & Development had always been the backbone of OCL's product supremacy. Apart from harnessing the fruits of in-house research for direct application to product and process development related spheres, OCL regularly commissions the services of Dalmia Institute of Scientific and Industrial Research (DISIR) in carrying out application oriented specific research projects. This immensely helps OCL to draw upon the knowledge of scientific community as well and use it for the betterment of both the industry and the consumer to whom the benefits of such research ultimately reach. A company is primarily known for the products it makes and the services it renders. In the ultimate count it is quality that holds the key. 'Konark' Brand cement of OCL has been extensively used in the construction of the prestigious Hirakud Dam in Odisha and in building some of India's largest roads, bridges and Industrial plants - including the Vidyasagar Setu in Kolkata ,the Gandhi Sagar Bridge in Patna , as well as in the construction of port facilities at Haldia and Paradip. OCL is proud that it was 'Konark' cement, which was exclusively used in essential restoration repairs by Archaeological Survey of India in Lord Jagannath Temple at Puri. To name a few remarkable Projects where Konark Cement has been recently used are Modernisation of TISCO/Jamshedpur plant, 2.2 Million ton Integrated Steel plant of Electro Steel Integrated in Bokaro, Jharkhand , A 3 Million ton Integrated Steel Plant of Jindal Steel and Power at Angul, Odisha An all-weather new private Port at Dhamara near Bhadrak in Odisha built jointly by TISCO and L&T placed confidence on Konark in using its cement. A first all concrete road connecting the busiest commercial town of Odisha with its only Port Paradip in underway with all its requirement met from Konark cement A 3 Million ton integrated steel plant of Bhushan Steel and Power along with 500mw of power plant placed its confidence on Konark for its

- 10. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 9 vital installations and used maximum quantity for installation of BF and other systems. Vedanta Aluminium, Jharsuguda -building a world class Aluminium Refinery and a 2400MW IPP is another testimony of the confidence placed in Konark. Besides these, numerous Large and medium projects of Irrigation, Power, Sponge Iron and Steel have used Konark cement in shaping up their dream which shows the confidence the brand enjoys in the minds of its consumers. As on date Konark Brand Cement enjoys rock solid customer satisfaction across the country and is very popular in the state of Odisha where for the last almost 60 years it is the most demanded premier lead brand. It is a name ‘Cemented to Quality’. After its recent up gradation and enhancement of its capacity, Konark Cement has entered into the states of Bihar where it has been so well received that it commands a substantial market share immediately after its entry in the markets. OCL is proud of its dedicated team of people - its employees, its ever- increasing list of satisfied customers, its dealers, its Bankers and Financial Institutions, its representatives and associates who have all immensely contributed to making what OCL is today.

- 11. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 10 According to the Indian Standard Specifications total 14 type of cement are available in India now. Indian standard Specification on cement: Title of the QC Order: Cement (Quality Control) Order 2003 QC Notification: Ministry of Commerce & Industry, Department of Industrial policy & promotion. Implementing Authority: Officers appointed by state /Central Govt. SL.NO Type of Cement 1. 33 Grade ordinary Portland Cement (OPC-33) (IS-269). 2. 43 Grade Ordinary Portland Cement (OPC-43) (IS-8112). 3. 53 Grade Ordinary Portland Cement (OPC-53/53S) (IS-12269). 4. Portland Slag Cement (PSC) (IS-455). 5. Portland Pozzolana Cement (PPC) (IS-1489). 1. Fly Ash based 2. Calcined Clay Based. 6. Sulphate resistant Portland Cement (SRPC) (IS-12330). 7. Masonry Cement (IS-3466). 8. Oil Well Cement (IS-8229). 9. High Alumina Cement for Structural Use (IS-6452). 10. Super sulphated Cement (IS-6909). 11. Rapid Hardening Portland Cement (IS-8041). 12. White Portland Cement (IS-8042). 13. Hydrophobic Portland Cement (IS-8043). 14. Low Heat Portland Cement (IS-12600).

- 12. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 11 Varieties of Cement, their properties & application. Ordinary Portland Cement 33 grade (IS-269). Ordinary Portland cement is generally made by grinding the Clinker with Gypsum. According to the BIS (Bureau of Indian Standard) the minimum compressive strength of 33 grade OPC cement should be 33MPa. Chemical Composition: OPC 33 grade is generally low C3S content 45% and where 95% clinker & 4-5 % gypsum were mixed. Properties : Chemical Properties(BIS Requirement): Properties %LOI %MgO %SO3 %IR %Cl LSF A/F OPC-33 5.0 6.0 *2.5/3.0 4.0 0.1 0.66- 1.02 0.66 Physical Properties(BIS Requirement): Properties Fineness: Specific Surface Area M2/Kg Setting time Compressive Strength(CCS) in MPa Soundness Initial Final 3-day 7-day 28- day LeChtelier In mm Autoclave (%) OPC-33 225 30 600 16 22 33 10 0.8 Applications. Used for general low-rise civil construction works under normal environmental conditions.

- 13. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 12 Ordinary Portland Cement 43 grade (IS-8112:1989). Ordinary Portland cement 43 grade is a moderate strength Portland cement where according to BIS requirement the compressive strength of this cement should not be less than 43 MPa after 28 days. Chemical Composition: The strength is obtained because of high percentage of C3S content about 50%.90-95% clinker is grinded with 4 to 5 % of gypsum to make this cement. Properties : Chemical Properties(BIS Requirement): Properties %LOI %MgO %SO3 %IR %Cl LSF A/F OPC-43 5.0 6.0 *2.5/3.0 3.0 0.1 0.80-1.02 0.66 Physical Properties(BIS Requirement): Properties Fineness: Specific Surface Area M2/Kg Setting time Compressive Strength(CCS) in MPa Soundness Initial Final 3-day 7-day 28- day LeChtelier In mm Autoclave (%) OPC-43 225 30 600 23 33 43 10 0.8 Applications. General civil engineering construction works including residential commercial & industrial buildings like roads, bridges, fly overs under normal environmental conditions. Pre-cast items such as blocks, tiles and pipes. Asbestos products such as sheets and pipes. Non-structural works such as plastering and flooring.

- 14. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 13 Ordinary Portland Cement 53 grade (IS-12269). 53-grade OPC is high strength cement. According to the BIS requirements, 53-grade OPC has a 28-day compressive strength of 53 MPa minimum. For certain specialized products, such as pre-stressed concrete and certain pre-cast concrete items requiring high strength, 53-grade OPC is considered useful as it can produce high-grade concrete at lower cement content levels. 53-grade OPC is produced by exposing the clinker to the grinding process for longer period of time, which results in a higher density and stronger cement. As the grinding process requires a significant amount of power, finer grinding for the 53-grade OPC requires more power and is therefore priced higher compared to lower grades of OPC. Chemical Composition: This a very high strength cement & this is obtained because of very high percentage of C3S content in the clinker about 52-53%.95% clinker is grinded with 4 to 5 % of gypsum to make this cement. Properties : Chemical Properties(BIS Requirement): Properties %LOI %MgO %SO3 %IR %Cl LSF A/F C3S Min C3A Max OPC-53 4.0 6.0 *2.5/3.0 3.0 0.1 .80- 1.02 0.66 OPC-53S 4.0 6.0 *2.5/3.0 3.0 .1 .80- 1.02 0.66 45.0 10.0 Physical Properties(BIS Requirement): Properties Fineness: Specific Surface Area M2/Kg Setting time Compressive Strength(CCS) in MPa Soundness Initial Final 3-day 7-day 28- day LeChtelier In mm Autoclave (%) OPC-53 225 30 600 27 37 53 10 0.8 OPC-53S 370 30 600 37.5 5 0.8

- 15. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 14 Applications. A high strength OPC is used for high rise buildings, bridges, flyovers, chimneys where high grade concrete is normally required. OPC-53S are used for railway sleeper making. Pre-cast concrete items such as paving blocks, tiles and building blocks. Pre-stressed concrete components and Runways, concrete roads and bridges. Portland Slag Cement (IS-455) Portland slag cement is now the most innovative product in the cement industry. Portland slag cement is made by grinding Portland cement Clinker with gypsum and Blast furnace granulated Slag obtained as a waste materials of iron Blast furnace of steel plants. It is also manufactured by blending OPC with ground granulated blast furnace slag (GGBS). Slag also contain that constituents contained in the raw materials so by mixing in intimate proportion of clinker and slag ultimate properties of cement can be obtained. This cement has strength comparable to OPC -33, 43, 53 Grade cement. It has very unique properties: It shrinkage is very low. It has very low water demand that mean very low %NC. It has high ultimate strength with higher rate of gain of strength than normal OPC available in market. Its strength gradually increases in longer period of time. PSC reduces the usage of clinker hence the cost of the cement decreases. Huge amount on waste from sponge iron industry are consumed in production of PSC cement so this way waste utilization is done. PORTLAND SLAG CEMENT

- 16. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 15 By producing PSC cement we can reduce the production of total CO2 in calcination process indirectly by producing low amount of Clinker. Chemical Composition: Portland slag cement is manufactured by grinding cement clinker, gypsum and 25-70% slag according to the requirement of strength. Chemical Composition of Slag: Properties : Chemical Properties(BIS Requirement): Properties %LOI %MgO %SO3 %IR %Cl %Slag PSC 5.0 10.0 3.0 3.0 0.1 25-70% Physical Properties(BIS Requirement): Properties Fineness: Specific Surface Area M2/Kg Setting time Compressive Strength(CCS) in MPa Soundness Initial Final 3- day 7- day 28- day LeChtelier In mm Autoclave (%) PSC 225 30 600 16 22 33 10 0.8 Applications: General civil engineering construction works

- 17. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 16 But mainly preferred for construction of marine structures and in coastal areas where excessive amount of chloride and sulphate are present. It can also be used for mass concrete works. Portland Pozzolona Cement (IS-1489) Portland pozzolona cement is also an environment friendly product of cement which uses hazardous substituents like “Fly ash” coming out from thermal Power plant. PPC is manufactured by grinding clinker with fly ash and gypsum with proper proportion. The major constituents of Fly Ash is SiO2 which is an essential components of Cement. According to BIS, the compressive strength of PPC cement should not be less than 33 MPa after 28 days. Some specific properties of this cement are: It is manufactured with carefully selected Pozzolana (Fly ash) as per the requirement laid down in IS 3812:1981 which is ideal for denser and more durable concrete. It is having low heat of hydration and corresponding resistance to exposure in various environmental chemicals such as salt water. It is particularly suitable for marine and hydraulic construction and other mass concrete structures. Chemical Composition: Portland Pozzolona Cement (PPC) is manufactured by grinding clinker, gypsum and 15-35% Fly Ash. Portland Pozzolona Cement

- 18. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 17 Chemical Composition of Fly Ash: Properties : Chemical Properties(BIS Requirement): Properties %LOI %MgO %SO3 %Fly Ash PPC 5.0 6.0 3.0 15-35% Physical Properties(BIS Requirement): Properties Fineness: Specific Surface Area M2/Kg Setting time Compressive Strength(CCS) in MPa Soundness Initial Final 3- day 7- day 28- day LeChtelier In mm Autoclave (%) PPC 225 30 600 16 22 33 10 0.8 Applications: Useful for general construction works and especially suitable for works in aggressive environmental conditions. It is employed for water retaining structures, marine works, mass concreting such as Dams, Retaining Walls, and sewage pipes. Fly Ash

- 19. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 18 Sulphate resistant Portland Cement (IS-12330) Among the four major substituents of Cement Tricalcium Aluminate (C3A: 3CaO,Al2O3) Substrate is reacts with sulphate salt present in soil and water forming TriCalcium Sulphoaluminate whose volume is more than twice of C3A thus induces a stress in the concrete leading to crack and disruption of these concrete. But this SRPC Cement is free from these effect by maintaining the proportion of constituents in Cement. SRPC cement is made by inter grinding the special quality of clinker and gypsum. Chemical Composition: The C3A component in the Clinker is controlled to very less percentage by proper raw mix design so that it can’t react with sulphate salt. Other Components are mixed accordingly. Properties : Chemical Properties(BIS Requirement): Properties %LOI %MgO %SO3 %IR %LSF C3A Max (C4AF+2C3A) Max SRPC 5.0 6.0 2.5 4.0 0.66- 1.02 5.0 25.0 Physical Properties(BIS Requirement): Properties Fineness: Specific Surface Area M2/Kg Setting time Compressive Strength(CCS) in MPa Soundness Initial Final 3- day 7- day 28- day LeChtelier In mm Autoclave (%) Sulphate Expansion In 14 days SRPC 225 30 600 10 16 33 10 0.8 0.045 Applications: Use for underground structures in sulphate salt rich environment, effluent treatment plants. Used in Sugar & other chemical industries where civil works are likely to be subjected to be sulphate attack.

- 20. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 19 Oil Well Cement (IS-8229) This is a special type of cement which is suitable in high pressure and temperature. This type of cement is specially formulated for petroleum industry foe cementing the steel casting the walls of the Oil wells. That’s why its name “Oil Well” Cement. The temperature of the wall ranges from 180-2500 C while the pressure varies from 1300-2000 Kg/Cm2 Features: This cement is specially formulated so that its slurry remain pumpable at this temperature and pressure for a required length of time. Chemical Composition: This special type of cement has very high C3S content ranging from 48-65 % which gives very high strength to the cement also the quantity of Gypsum is reduced for easy setting. The percentage of C3A are also reduced to less than 3%. Properties : Chemical Properties(BIS Requirement): Proper ties %LOI %Mgo %SO3 %IR Max C3S Min C3S Max C3A Max (C4AF+2C3A) Max Na2O Max Oil Well 3.0 6.0 3.0 0.75 48.0 65.0 3.0 24.0 0.75 Physical Properties(BIS Requirement): Properties Initial Consistency (BC) CCS at (MPa) (Min) Soundness Thickening Time At 38oC At 60oC %of Water by mass of fluid %of Free Fluid max %of Free Water max Autoclave Expansion (%) (in minutes) Oil Well 30 2.1 10.3 44.0 5.9 1.4 0.8 90-120 Applications: Used for the petroleum industry for cementing the steel casting to the walls of the oil wells.

- 21. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 20 Masonry Cement (IS-3466) Masonry Cement is a special type of Cement which is exclusively used for Plastering and brick work. It is very smooth and gives super surface finish .Masonry Cement is produced by intimately grinding Portland cement clinker with pozzolonic materials or inert materials and gypsum. Special Features: It has low compressive strength that is why it can’t be used for structural concrete, flooring and foundation work. It contains air-entering agents which improve air retentivity, Plasticity, and workability of motors. Very smooth and super surface finish of the plasters. More plastic mortar mix. Minimum fall of mortar while plastering walls or ceiling. Properties: All properties are in Chart 1.a following. Applications: Used for making mortars for brickwork. Exclusively used for plastering works. Used for smooth surface finishing works. High Alumina Cement (HAC) (IS-6452). Essentially it is refractory cement. It has got high early strength development due to its high C3A content and low Gypsum Content. It got nearly 30 MPa in only one day. According to BIS requirement the proportion of Alumina in the cement should not be less than 32.0%. Super Sulphated Cement (SSC) (IS-6909). This Cement is typically formulated for resisting the high concentrated sulphur attack.

- 22. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 21 Applications: Used for a variety of aggressive conditions e.g. marine structures. Used in reinforced concrete pipes in ground water. Concrete construction in sulphur bearing soils. Chemical works involving exposure to high concentration of sulphates Concrete sewers carrying industrial effluents. Rapid Hardening Cement (RHC) (IS-8041). This cement is basically ordinary Portland cement with very high fineness. This type of cement is specially used for repairing and rehabilitation works are done where the speed of construction is fast and early completion is required due to the limitation of work. White Portland cement (WPC) (IS-8042). Meant for non-structural and decorative use. Normally used for flooring, general architectural purposes, such as mosaic tiles, decorative concrete wall paintings and special effects. Hydrophobic Portland cement (HPC) (IS-8043). Manufactured specially for high rainfall areas to improve the cement’s self- life. During manufacture the cement particles are given a chemical coating which imparts water repelling property where by the cement is not affected by high humidity and hence be stored without deterioration for a longer period. Low Heat Portland cement (LHC) (IS-12600). Used for making concrete for dams and other water retaining structures, bridge abutments, massive retaining walls etc. In mass concreting, there is often considerable rise in temperature from the heat of hydration of the cement with resultant expansion, and the slow rate at which it is dissipated from the surface. The shrinkage which takes place on subsequent cooling may develop cracks.

- 23. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 22 Chart of BIS Requirement of properties :

- 24. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 23 Basic Components of cements. Cement has these four major constituents Calcium, Silicon, Iron, and Aluminium. They are in the form of: Tricalcium Silicate (C3S) Dicalcium Silicate (C2S) Tricalcium Aluminate (C3A) Tetracalcium Aluminoferrite (C4AF) Apart from this other constituents as additives are Gypsum CaSO4,2H2O (CSH2), Calcite CaO.CO3(CC). The source of these constituents in cement are mainly two type of raw materials they are:- Calcareous Raw Materials. Argillaceous Raw Materials. Each component of the raw mix has individual(C, A, S and F) and combined [(Lime Saturation Factor (LSF), Silica Modulus (SM), Alumina Modulus (AM),] effects on burnability. The formula, limiting range and the preferable range of the LSF, SM & AM is shown in table. Parameter Formula Limiting Range Preferable Range LSF 0.66-1.02 0.92-0.96 SM 1.9-3.2 2.3-2.7 AM 1.5-2.5 1.3-1.6 The different source of these above type of raw materials are following. Calcium (Ca) Silicon (Si) Iron (Fe) Aluminium (Al)

- 25. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 24 Mainly supply CaO

- 26. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 25

- 27. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 26 Although Now a days some alternative raw materials except above are used for production of cement. Like – Handling of raw materials. Lime stone are the predominant raw materials for cement which accounts for the 60% of the total raw materials of cement and its quality ultimately characterises the quality of cement. So proper handling of raw materials is necessary for ensuring the quality of cement. Time to time limestone samples are tested in the laboratory to evaluate the deposit of quarry by Computer Aided Deposit Evaluation done by M/s Holtech Consultancy. Day by day drill dust samples analysis are done at laboratory and the results are communicated to quarry enabling them to preblend for dispatching the uniform quality of limestone. As per the preblend, Limestone is dug vertically from the open cast mines after drilling and blasting loaded on to the dumpers which transport the materials into the hoppers of the limestone crusher which grind the lime stone into 75 mm size. Crushed limestone are blended by stacker and Reclaimer for ensuring proper blending. Then the crushed limestone is transported to the plant by Cross Country Belt Conveyer (CCBC) or Narrow Gauge Train Line. Morrum are collected locally by truck and feed into hopper. Slug is collected from iron industry. Fly ash is transported by closed truck from Thermal Power Plant. Coal taken from Coal mines although now a days Pet Coke are used as alternative fuel. CCBC

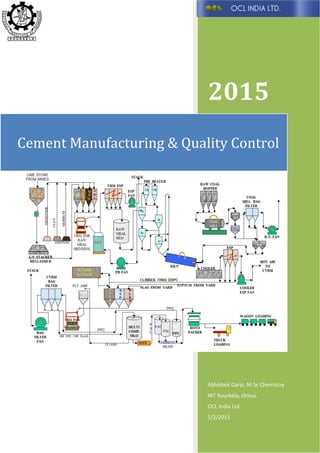

- 28. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 27 Morrum Sandstone Clay Hopper for proper Raw mix Design Grinding Raw Meal Raw Meal Silo Vertical Roller mill for Grinding. Preheater Rotary Klin Clinker Production Process Co al Firi ADDITIVES (Gypsum, Slag, Fly Ash)

- 29. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 28 The cement manufacture process from the mines to packing of cement can be divided into five steps: Raw materials acquisition and handling. Kiln feed preparation. Clinker Production (Pyro-Processing). Finished grinding. Packing & Dispatch. Each of these steps are described briefly below. Raw materials acquisition and handling: The initial production step in Portland cement manufacturing is raw materials acquisition. Calcium, the element of highest concentration in Portland cement, is obtained from a variety of calcareous raw materials, including limestone, chalk, marl, sea shells, aragonite, and an impure limestone known as "natural cement rock". Typically, these raw materials are obtained from open-face quarries, but underground mines or dredging operations are also used. Raw materials vary from facility to facility. Some quarries produce relatively pure limestone that requires the use of additional raw materials to provide the correct chemical blend in the raw mix. The raw materials are selected, crushed, and proportioned so that the resulting mixture has the desired the minimum percentage of chemical composition requirement of raw materials. Because a large fraction (approximately one third) of the mass of this primary material is lost as carbon dioxide (CO2) in the kiln, Portland cement plants are located close to a calcareous raw material source whenever possible. The raw materials limestone is then transported to the plant by Cross Country Belt Conveyer (CCBC) or by railway wagons. Stacking and Reclaiming of Limestone: After crushing, the crushed limestone is piled longitudinally by an equipment called stacker / reclaimer. The stacker deposits limestone longitudinally in the form of a pile. The pile is normally 250 to 300 m long and 8-10 m high. The reclaimer cuts the pile vertically, simultaneously from top to bottom to ensure homogenization of limestone.

- 30. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 29 The crushed limestone from pile is transported through belt conveyor to hopper. Similarly, other raw materials like clay, morrum, sand stone etc. are also transported by belt conveyor from storage yard to respective hoppers. All raw materials are proportioned in requisite quantity through weigh feeders. Crushing Stacking and Reclaiming of Coal: The process of making cement clinker requires heat. Coal is used as the fuel for providing heat. Raw Coal received from collieries is stored in a coal yard. Raw Coal is dropped on a belt conveyer from a hopper and is taken to and crushed in a crusher. Crushed coal discharged from the Coal Crusher is stored in a longitudinal stockpile from where it is reclaimed by a reclaimer and taken to the coal mill hoppers for grinding of the coal. Stacker of Limestone Stacker of Coal Reclaimer of Lime Stone Reclaimer of Coal

- 31. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 30 Kiln Feed preparation: The second step in Portland cement manufacture is preparing the raw mix, or kiln feed, for the pyroprocessing operation. Raw material preparation includes a variety of blending and sizing operations that are designed to provide a feed with appropriate chemical and physical properties. Based on Raw mix design and availability of additives and quality of limestone received, proportioning of raw materials is achieved through electronically controlled weigh feeders. Cement raw materials are received with an initial moisture content varying from 1 to more than 50 percent. If the facility uses dry process kilns, this moisture is usually reduced to less than 1 percent before or during grinding. Drying alone can be accomplished in impact dryers, drum dryers, paddle-equipped rapid dryers, air separators, or autogenous mills. However, drying can also be accomplished during grinding in ball-and-tube mills or roller mills. While thermal energy for drying can be supplied by exhaust gases from separate, direct-fired coal, oil, or gas burners, the most efficient and widely used source of heat for drying is the hot exit gases from the pyroprocessing system. Raw Mix design:

- 32. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 31 Limestone and other additives in desired proportions are fed to Vertical Roller Mill (VRM) by belt conveyer where they are ground to fine powder. A part of the hot exit gas (from the kiln) that has been sucked by the pH fan is sent to VRM through GAS CONDITIONING TOWER (GCT-to reduce temperature) to remove the moisture in the raw materials. The dust produced is carried by the hot gas and it is separated by Electro Static Precipitator (ESP) by charging the dust particles which then fall into hopper for recycling. The ‘Raw Meal’ produced after grinding by Vertical roller mill is air swept from inside from VRM and transported to specially designed ‘RAW MEAL SILO’ where blending is done by injecting compressed air for maintaining its homogeneous nature. VRM: Raw meal is ground in VRM to give a residue of +90µm 12-14%. VRM contains a horizontal circular table rotated by a motor and three conically tapered grinding roller. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the mill, the re-grinding; powder while grinding out with air, dust collection equipment in the system to collect down, that is, products.

- 33. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 32 Established through the mill in the pneumatic conveying of materials, a larger air flow rate, which can use waste heat of gas, at the same time dry grinding operations. ESP: An electrostatic precipitator (ESP) is a filtration device that removes fine particles, like dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit. Clinkerisation (Pyroprocessing): The heart of the Portland cement manufacturing process is the pyroprocessing system. This system transforms the raw mix into clinkers, which are grey, glass-hard, spherically shaped nodules that range from 0.32 to 5.1 centimetres (cm) (0.125 to 2.0 inches [in.]) in diameter. The pyroprocessing system of clinkerisation section consists of a rotary kiln with 5 stage preheater with in line precalciner. In the preheater the raw meal gets heated up with the use of kiln waste gases, and in the precalciner the raw meal is partially calcined to the extent of 85 to 95% by partly firing coal in the precalciner with the help of hot air recovered from clinker cooler. The partially calcined raw meal enters the rotary kiln. Coal, ground to desired fineness is fired into kiln from the discharge end. In these rotary kilns a tube with a diameter up to 25 feet is installed at a 3-4 degree angle that rotates 1-3 times per minute. The ground raw material, fed into the top of the kiln, moves down the tube counter current to the flow of gases and toward the flame-end of Preheater

- 34. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 33 the rotary kiln, where the raw meal is dried, calcined, and enters into the sintering zone. In the sintering (or clinkering) zone, the combustion gas reaches a temperature of 3300-3600 °F. While many different fuels can be used in the kiln, coal has been the primary fuel although now a days Pet Coke (Bi-Product of petroleum industry) are also used. The raw mix in the kiln melts first into liquid form and then transforms into nodules due to the effect of the rotation of the kiln. There are two zones inside the kiln, namely calcining zone and burning zone. The zone where raw mix enters into the kiln is called calcining zone. Where temperature would be 950- 1000 C. Burning zone starts after this zone where temperature would be 1350-1450 C. The chemical reactions and physical processes that constitute the transformation are quite complex, but they can be viewed conceptually as the following sequential events: 1. Evaporation of free water; 2. Evolution of combined water in the argillaceous components; 3. Calcination of the calcium carbonate (CaCO3) to calcium oxide (CaO); 4. Reaction of CaO with silica to form dicalcium silicate; 5. Reaction of CaO with the aluminium and iron-bearing constituents to form the liquid phase; 6. Formation of the clinker nodules; 7. Evaporation of volatile constituents (e. g., sodium, potassium, chlorides, and sulphates) 8. Reaction of excess CaO with dicalcium silicate to form tricalcium silicate. After the formation of clinker cooling is necessary for quality maintenance. The temperature of the clinker is brought to 80-90 oC from 1350-1450 oC by Clinker Cooler. Fast cooling is very essential to get good Rotary Kiln

- 35. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 34 quality clinker. If cooling is not quick, the compound stability in clinker will be adversely affected resulting in lower strength of cement after grinding. The hot gas produced in the clinker cooler is used in kiln, VRM and pyro cyclone. The cooled clinker produced are transported to Clinker storage Silo by Deep Drawn Pan Conveyer (DDPC). Clinker

- 36. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 35

- 37. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 36 Finish Grinding: The final step in cement manufacturing involves a sequence of blending and grinding operations that transforms clinker to finished cement. To produce powdered cement clinker is ground to the consistency of face powder. The clinker from silos are fed into grinding ball mill or vertical roller mill along with requisite amount of gypsum and other additives like Fly ash , Slag etc depending on the requirement of proper strength, setting time. Packing & Dispatch: The Cement produced after grinding are stored in silos from where it is extracted to automatic rotopackers with electronically controlled weight capacity. When the cement packing bag is of 50 kg it will automatically stop pouring into that bag after the bag will be automatically sealed and transported to bag cement storage. After that cement is being loaded in the wagons and racks through automatic loaders and finally dispatch in rail and road. VRM Automatic Rotopackers

- 38. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 37 The quality of cement in India is maintained according to “Bureau of Indian Standards” specifications. The quality is assured by the analysis of raw materials, clinker, and cement in regular basis according to BIS procedure. Apart from that the processing parameter in Kiln, silo, VRM are also maintained by CCR. ASSURENCE PROCEDURE: Objective: a) Ensuring the quality of the incoming, intermediate, semi-finished and final product. b) Ensuring conformity with the laid down norms by BIS (Bureau of Indian Standards.) QUALITY CONTROL OF INCOMING MATERIALS. LIMESTONE: Limestone is the predominant raw materials in cement manufacturing its quality ultimately characterises the quality of clinker and cement. Time to time limestone samples are tested at laboratory to evaluate the deposit of quarry by computer aided Deposit Evaluation by M/S Holtech Consultancy. Day to day drill dust samples analysis are done at laboratory and the results are communicated to quarry enabling them to make the pre blend for dispatching the uniform quality of lime stone. As peer pre blended, limestone are crushed and loaded in the hopper and finally it is transported to the plant by Cross Country Belt Conveyer sometimes by Narrow Gauge Train lines. The material is stacked horizontally trough stacker to form a cheveron type of stockpile up to a quantity of 1500 MT. During stacking the quality is monitored and the samples are being collected from the belt in hourly basis through a continuous auto sampling

- 39. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 38 system and analysed through X-Ray analyser. The test results are fed to the quarry on hourly basis to take the necessary correction before the next dispatch to meet the prefixed norms for every 5000 MT stock. The cumulative chemical composition of the limestone stockpile is estimated based on the hourly test results and use to prepare the raw mix design. QUALITY CONTROL OF OTHER ADDITIVES: Clay, Fly ash, Cinder, Morrum are the additives are generally used in the raw meal although some other additives are also can be used. Received raw materials are tested to check its conformity w.r.t the predefined norms. The test data are used for preparing the raw mix design. Coal is used mainly as a fuel although Pet coke are also used now a days. Received Coal and pet Coke are tested to check its conformity w.r.t to the predefined norms. Blast furnace granulated slag, fly Ash, and gypsum are used in the cement grinding stage. The received materials are tested to check its conformity w.r.t to predefined norms laid down by BIS. QUALITY CONTROL OF RAWMEAL. Raw Meal: Limestone stockpile is being reclaimed vertically trough a reclaimer to get a uniform quality of limestone all along. The limestone is intimately mixed with known quality of argillaceous materials in a definite proportion through weigh feeders as determined by the QCX blend expert system based on the quality targets of the raw meal determined through raw mix design. This mixed materials is ground in a vertical roller mill. The mill output materials is stored inside the specified silos. During grinding process samples are being collected on hourly basis through a continuous auto sampling system and being tested through X-Ray fluorescence spectrometer. The results are in turn fed to QCX blend expert system to change the proportion of raw materials to meet the target values.

- 40. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 39 QUALITY CONTROL OF INTERMEDIATE MATERIALS. Clinker: The raw meal from the silo is fed to the kiln through two string five stages preheater with inline calciner and sintered at a temp of 1400 degree centigrade for complete clinker formation. The clinker is then passed through a grade cooler and stored in the Clinker Gantry. The fuel used in the pyro system is coal pulverised through a ball mill and the samples is being taken to check and maintain the ash content to meet the target value. Hourly clinker sample is collected from DDPC and is being tested by X-Ray Fluorescence spectrometer and X-ray Diffractometer for their complete elemental composition and phase evaluation. This definitely helps for controlling and monitoring the clinker quality as per the target designed value on hourly basis and for taking any effective action in the raw meal if required. QUALITY CONTROL OF FINAL PRODUCT. Cement Grinding: Known quality of Clinker, Gypsum, Slag, Fly Ash are fed into respective hoppers of the grinding mills from which required proportion of these materials are fed to the mills through weigh feeders as per the requirement of manufacturing different quality of cement. Mills out samples are collected through continuous auto sampling system a tested for complete quality evaluation and taking necessary corrective actions. Cement Packing: Finally the cement is packed through automatic rotopackers. During packing samples are being collected through autosamplers on hourly basis to assure the quality of cement supplied to the customers. Ensuring Conformity with the laid down norms by BIS To ensure the compliance of statutory requirements of BIS following activities are performed-

- 41. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 40 All IS specifications required for carrying out the quality control functions are identified and kept in a separate file at an identified location. Incase of any amendment or change in version of IS specification the old one is replaced and new version is incorporated in the file. The test records related to the quality input and output of the products required to provide evidence of conformity to the IS requirements are maintained and duly signed by the respective authorised person. Sectional Incharge is authorized to ensure compliance of statutory requirements of BIS. Action is initiated for timely renewal of the product licenses. The following analysis are done in prescribed time intervals for assuring the quality -

- 42. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 41 Total 3 type of tests are done in cement industry namely 1. Chemical Analysis. 2. Physical Analysis. 3. Fuel Analysis. Chemical Analysis (Various Technique used for analysis and their principle of operation): Chemical analysis is required in cement manufacture for evaluating the quality of raw materials, raw meal & finish grinding product and for effecting quality control. Chemical composition is determined by two methods- Instrumental Techniques. Laboratory tests. Instrumental Techniques. Now the chemical composition and other properties of cement, clinker, raw materials can be is easily determined by using instrument like - 1. X-ray Fluorescence Spectrometer. 2. X-Ray Diffraction. 3. Microscope. 4. Flame Photometer. Let us discuss about those instruments and their principle of operation. Principle: Samples for X-ray fluorescence are prepared by grinding the samples with cellouse power and then pressed under the pressure of 20 ton for 10-15 seconds and make sample pellet. The samples are excited by an X-ray radiation produced in X

- 43. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 42 ray tube operated in a potential between 10-100 kv. When materials are exposed to short wavelength X-rays or to gamma rays, ionization of their component atoms may take place. Ionization consists of the ejection of one or more electrons from the atom, and may occur if the atom is exposed to radiation with an energy greater than its ionization potential. X-rays and gamma rays can be energetic enough to expel tightly held electrons from the inner orbitals of the atom. The removal of an electron in this way makes the electronic structure of the atom unstable, and electrons in higher orbitals fall into the lower orbital to fill the hole left behind. In falling, energy is released in the form of a photon, the energy of which is equal to the energy difference of the two orbitals involved. Thus, the material emits radiation, which has energy characteristic of the atoms present. The term fluorescence is applied to phenomena in which the absorption of radiation of a specific energy results in the re-emission of radiation of a different energy (generally lower). The intensity of these characteristic radiation is measured with a suitable x ray spectrometer and it is compared with standard samples. Calibration: In preparing an analytical program to measure unknown concentration trough XRF it is necessary to make a series of standard samples with known concentrations for all the elements to be measured .These samples are called calibration samples. Calibration samples are grouped by matrices. The name of the matrices represents the link with a

- 44. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 43 calibration is a process to relate measured element intensities of concentration. Procedure: For a particular analytical program minimum 6 samples of the same matrix and different range of element are to be selected and analysed trough conventional method of chemical analysis. The samples are to be pelletized as per WI No CFQA0308. Intensity is measured for the programmed element. These intensity are stored in computer under selected analytical program. Element wise chemical analysis data (concentration) of different samples are also stored for that particular analytical program. The computer plots calibration curve for each of the element for the particular analytical program. When an unknown samples is excited with X ray radiation it emits the fluorescence radiations with characteristic wavelength of each elements. The intensity of those fluorescence radiation of each element are measured and compared with that of the standard samples from the calibration curve to calculate the corresponding concentration. Calibration Curve

- 45. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 44 X-ray powder diffraction (XRD) is a rapid analytical technique primarily used for phase identification of a crystalline material and can provide information on unit cell dimensions. The analysed material is finely ground, homogenized, and average bulk composition is determined. Principle: Max von Laue, in 1912, discovered that crystalline substances act as three-dimensional diffraction gratings for X-ray wavelengths similar to the spacing of planes in a crystal lattice. X-ray diffraction is now a common technique for the study of crystal structures and atomic spacing. X-ray diffraction is based on constructive interference of monochromatic X-rays and a crystalline sample. These X-rays are generated by a cathode ray tube, filtered to produce monochromatic radiation, collimated to concentrate, and directed toward the sample. The interaction of the incident rays with the sample produces constructive interference (and a diffracted ray) when conditions satisfy Bragg's Law (nλ=2d sin θ). This law relates the wavelength of electromagnetic radiation to the diffraction angle and the lattice spacing in a crystalline sample. These diffracted X-rays are then detected, processed and counted. By scanning the sample through a range of 2θ angles, all possible diffraction directions of the lattice should be attained due to the random orientation of the powdered material. Conversion of the diffraction peaks to d-spacings allows identification of the mineral because each mineral has a set of unique d-spacings. Typically, this is achieved by comparison of d-spacings with standard reference patterns. All diffraction methods are based on generation of X-rays in an X-ray tube. These X-rays are directed at the sample, and the diffracted rays are collected. A key component of all diffraction is the angle between the incident and diffracted rays. Powder and single crystal diffraction vary in instrumentation beyond this.

- 46. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 45 Applications: XRD is used for phase identification of cement clinker. Difficulty in cement identification results in large peak overlap but also in large polymorphs coexistence. Indeed, C3S exists in 3 different forms: Monoclinic, Triclinic and Rhomboedric. C2S can also exist in 3 different polymorphs: α, β and γ. However, C2S beta is the most used and expected due to its reactivity; it is the most common in cement. α shows a slower reactivity and γ does not react. C3A is also well known to have two possible polymorphs in cement like cubic or orthorhombic phases. Moreover, more to the polymorph coexistence, some trace phases are present (lime, portlandite, periclase…) and some additives are added in cement to improve final properties. Gypsum is one of them and will control the milling dehydration process; this phase is often accompanied with bassanite, anhydrite and hemi hydrate phases. Phase identification takes place in three steps: background subtraction is the first one and it is always required in this kind of material, then a peak finder procedure has to be performed and finally a search/match can be processed quickly. For a more efficient search/match, a cement database can be created with the software. Scan of calcium aluminate cement during hydration process Peak intensity variation during hydration

- 47. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 46 A valuable, simple, very handy, inexpensive, low maintenance cost quality control tool for quality evaluation of clinker, limestone, kiln feed, aggregates and slag. Common Morphological features of clinker phases.

- 48. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 47 Optical Properties of Clinker Phases. Sl.no Clinker Phase Colour Shape Microstructure 1. ALITE-C3S (3CaO,SiO2) STRAW YELLOW, BROWN, YELLOWISH BROWN, BROWNISH YELLOW HEXAGONAL, PSEUDO- HEXAGONAL, LATH, SUBHEDRAL, ANHEDRAL ETC. FUSED GRAINS, STRETCHED, TWINNED, GRANULATED, BROKEN OUT LINE GRAIN 2. BELITE-C2S (2CaO,SiO2) BLUE, BLUISH YELLOW YELLOWISH BLUE,GREENISH YELLOW, YELLOWISH GREEN ROUNDED SUB ROUNDED ELLIPTICAL, SUBHEDRAL, ANHEDRAL ETC. CLUSTERS OF VARIOUS SIZE, FUSED GRAINS, TWINNED GRAINS, CORRODED GRAIN MARGINS, STRIATIONS ON BELITE GRIN SURFACES, AS INCLUSION. 3. FREE LIME - CaO MULITPLE HIGH ORDER INTERFERENCE COLOURS OF PINK, GREEN, YELLOW, BLUE ETC. ROUNDED, SUB- ROUNDED, SUBHEDRAL, ANHEDRTAL ETC. CLUSTERS, STRIATIONS ON THE GRAIN SURFACES, AS INCLUSIONS

- 49. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 48 Pictures of different forms: By using this microscopic technique both qualitatively and quantitatively we can measure the phases and composition in clinker and cement in different forms. A photoelectric flame photometer is a device used in inorganic chemical analysis to determine the concentration of certain metal ions, among them sodium, potassium, lithium, and calcium. Group 1 and Group 2 metals are quite sensitive to Flame Photometry due to their low excitation energies. Alite Balite Free Lime

- 50. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 49 In principle, it is a controlled flame test with the intensity of the flame colour quantified by photoelectric circuitry. Flame photometry is concerned with the emission of characteristic radiation in flame and correlation of emission intensity with the concentration of the solution. When a liquid sample containing a metallic salt solution is introduced in the flame, the solvent get vaporized leaving particles of the solid salt. The atoms are ionised and get thermally excited and go to the higher energy state, when they come into lower energy state these atom release same amount of energy. If E1 and E2 represent the higher and lower energy state respectively then the radiation emitted during the transition may be defined as the following equation E1-E2=hγ. So the intensity of the colour will depend on the energy that had been absorbed by the atoms that was sufficient to vaporise them. The sample is introduced to the flame at a constant rate. Filters select which colours the photometer detects and exclude the influence of other ions. Before use, the device requires calibration with a series of standard solutions of the ion to be tested. From this flame photometry chemical composition in of unknown cement sample, raw materials can be determined through calibration plot with respect to the intensity of standard solution. Instrumentation:- Generally the flame photometer has six parts i. Pressure Regulator ii. Atomizers iii. Burner iv. Optical System v. Photosensitive Detector vi. Instrument for recording the output of the detector.

- 51. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 50 Procedure:- 1. Turn on the flame photometer and adjust the air pressure to 0.5 Kg/cm2.Adjust the fuel and light of the burner to get a clear conical flame. 2. Rinse the atomiser with distilled water for half an hour. 3. Select the filter what you want to determine like Na2O, K2O etc. 4. Aspirate the reagent blank solution and set the digital reading at 0. 5. Aspirate the 10 ppm solution and adjust the digital reading at 100. 6. Readjust the zero with blank. 7. Aspirate the 1,2,4,6,8,10 ppm solution and note the reading. 8. Draw the calibration curve of ppm vs digital reading. 9. Now the ppm of the unknown samples are estimated by using the following formula. PPM= Concentration in ppm * Volume in ml *Dilution Factor *100 Weight of the samples * 106 Laboratory Tests. Although various methods are available for the quantitative estimation of the different composition in cement, clinker, raw materials. But in India the estimation is done by following “IS-4032- 1985” procedure of Bureau of Indian Standards. Conventional chemical analysis is done mainly on two methods – 1. Gravimetric Method. 2. Volumetric and Complexmetric Method. 1. Gravimetric Method. It is the process of sequential & weighting an element or definite compound of the element in as pure form as possible. The compound is precipitated filtered and then ignited t give the most suitable form of the element for weighting. 2. Volumetric and Complexmetric Method: It is quantitative chemical quantitative chemical analysis by measure consists essentially in determining the volume of the solution of accurately known concentration which required to react quantitatively with the substrate being determined. In Complexmetric method the metals react with the indicator and gives a colour at a controlled pH. The volume of the

- 52. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 51 polydentate ligand complexes with the metal cation realising the indicator. Which gives a different colour. Chemical analysis is done mainly to determine the following things. % of LOI (Loss on Ignition). % of Fe2O3. % of CaO. % of SiO2. % of MgO. % of SO3. % of Na2O % of K2O. % of LOI (Loss on Ignition): Loss on ignition is determined by taking a known weight of sample approx. 1.0 gm accurately weighted in a platinum crucible and heated in a Muffle Furnace for 15-20 min in a temperature range of 1000-1200 o C. Then the sample is cooled in desiccator and the weight of the sample taken. Repeat the procedure till the constant weight observed. Loss on ignition = (W1-W2)*100 W W1= Weight of the sample + Weight of the crucible. W2= Weight of the empty crucible. W = Weight of the sample taken. % of Fe2O3 Procedure for determination of Fe2O3 by K2Cr2O7 in Clinker, Cement and Gypsum:

- 53. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 52 1. 1 gm of sample is weighted accurately and taken in 400 ml Beaker and dissolved in concentrated HCl and around 100 ml of distilled water and transfer in 500 ml conical flask. 2. The solution is boiled with some porcelain chips. 3. Fe 3+ is reduced to Fe 2+ by adding SnCl2 drop wise till the solution become colourless. Rxn: Sn2+ - 2e Sn4+ 2Fe3++2e 2 Fe2+ 4. The flask is cooled rapidly to room temperature and 20-25 ml Mercuric Chloride is added followed by sulphuric Orthophosphoric acid into the solution. 5. 3-4 drops of Barium Di-phenyl amino sulphonate indicator is added and titrate against (N/16) K2Cr2O7 solution till a stable violet –blue end point appears. 6. % of Fe2O3 = ( Consumption of K2Cr2O7)/2 Procedure for determination of Fe2O3 by K2Cr2O7 in LIMESTONE, Additives and other than MORRUM and Raw Meal. 1. Weight accurately 1 gm of sample in a platinum crucible 2. Add around 8-10 gm of fusion mixture in it and fuse it in a muffle furnace at 950 C for 15-20 min. 3. Extract the sample with 1 N of 100 ml of 1:1 HCl. 4. Add 5-6 of Bromine water to the solution and keep it on heater till complete evaporation of the Bromine Water. 5. Remove the solution from the heater and around 10 gm of solid Ammonium chloride and dissolve it by stirring with a glass rod. 6. Add ammonium hydroxide drop wise to the solution till complete precipitation. 7. Warm the solution on the heater and filter through 541 whatmann filter paper. 8. Wash the residue with hot distilled water. 9. Transfer the residue in a 500 ml conical flask and dissolve in concentrated HCl. 7. The solution is boiled with some porcelain chips.

- 54. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 53 8. Fe 3+ is reduced to Fe 2+ by adding SnCl2 drop wise till the solution become colourless. Rxn: Sn2+ - 2e Sn4+ 2Fe3+ + 2e 2 Fe2+ 10. The flask is cooled rapidly to room temperature and 20-25 ml Mercuric Chloride is added followed by sulphuric Orthophosphoric acid into the solution 11. 3-4 drops of Barium Di-phenyl amino sulphonate indicator is added and titrate against (N/16) K2Cr2O7 solution till a stable violet –blue end point appears. 12. % of Fe2O3 = ( Consumption of K2Cr2O7)/2 13. % of Fe2O3 = ( Consumption of K2Cr2O7)*2.5 (for Morrum) Calculation: Molar Weight of Fe2O3 = (55.847*2) +48 = 159.694 Molar weight of K2Cr2O7 = (39.0983*2) + (51.996*2)+16*7=294.1886 1 N K2Cr2O7 = (294.1886/6)=49.03 gm 1 N K2Cr2O7 = 159.694/2=79.847 gm Fe2O3 1 ml of 1 N K2Cr2O7 =0.07985 gm of Fe2O3 For 0.5 gm sample if we want to recg. a factor of 1 the normality of the K2Cr2O7 solution will be – F= Normality of K2Cr2O7 *0.07985*100/0.5 Normality = (1*0.5)/(0.07985*100)=0.62617N=(N/16) % of CaO: Procedure for determination of CaO by KMnO4 for GYPSUM, CLINKER, and CEMENT: 1. 0.5 gm of sample is weight and take in 500 ml beaker. 2. Dissolve it with concentrated HCl and some distilled water is added to make the solution. 3. One two drop of methyl orange is add and heat. 4. Reduce the colour of the solution by drop wise addition of ammonium hydroxide of yellow colour.

- 55. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 54 5. Again add oxalic acid and bring the colour to red. 6. Add 50 ml of ammonium oxalate to the boiled solution. 7. Cool down to 50-60 C then filter with whatmann 41 and wash the residue with distilled water. 8. Titrate against 0.18 N KMnO4 solution. 9. % of CaO= Consumption of KMnO4*factor. Preparation and standardisation of KMnO4 Solution and determination of Factor. 1. Dissolve 5.6 gm of KMnO4 per litre distilled water and mix it properly. 2. Standardise the solution by taking 0.67 gm of sodium oxalate and dissolving it 10 ml 1:1 H2SO4 mixed with 10 ml of hot distilled water. Then titrate against the prepared KMnO4 soln. Let’s the consumption be X ml Factor = (Consumption of KMnO4 soln)/56. Procedure for determination of CaO by KMnO4 for LIMESTONE, CLAY, SHALE, MORRUM, RAW MEAL AND COAL ASH: 1. Weight accurately 1 gm of sample in a platinum crucible. 2. Add around 10-15gm of fusion mixture and heated in a muffle furnace at 900 C for 15 minutes. 3. Extract the sample with 1 N of 100 ml of 1:1 HCl. 4. Add 5-6 of Bromine water to the solution and keep it on heater till complete evaporation of the Bromine Water. 5. Remove the solution from heater and add 10 gm of Ammonium chloride added and dissolve it by stirring it by glass rod. 6. Add Ammonium hydroxide drop wise until precipitation. 7. Warm the solution on heater and filter it through whatmann 541 filter paper. 8. Collect the filtrate in 600 ml beaker and wash the residue by hot distilled water for two three times. 9. Boil the filtrate and add boil Ammonium Oxalate about 80 ml and further boil it. 10. Cool the solution and allow the precipitate to settle down. 11. Filter the solution through double 41 filter paper and wash the precipitate by distilled water.

- 56. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 55 12. Take out the precipitate along with the filter paper and dissolve it by 15 ml 1:1 H2SO4 along with 15 ml of distilled water. 13. Titrate against 0.18 N of KMnO4 14. % of CaO = (Consumption of KMMnO4 solution/2)* Factor. 15. The factor is determined as per the method described earlier. % of SiO2 1. SiO2(Silicon dioxide) Silica is one of the major constituents of the raw materials required for cement. It is usually analysed by volumetric method. The soluble silicates e.g. Clinker and cement are decomposed by HCl, The insoluble silicates like clay and pozzolanic materials, raw mix are made soluble by treating with fusion mixture. This is followed by double evaporation to convert silicon dioxide to insoluble form. The solution is filtered and the insoluble silica in residue is ignited and weighted. Silicon dioxide is volatilized in the form of silicon tetra fluoride by hydrofluoric acid in presence of sulphuric acid. The loss of weight is reported as pure SiO2. The reaction involved are following- MSiO3+2HCl=MCl2+H2SiO3 m= Silicic Acid 2MSiO3 + Na2O3+K2CO3 = 2MCO3 + Na2SiO3 + K2SiO3 Insoluble silicate Fusion Mixture MCO3+ Na2SiO3+K2SiO3+6HCl = MCl2+2NaCl+2KCl+CO2 +2H2SiO3+H2O H2SiO3+H2O=H2SiO4 H2SiO4 +nH2O= H2SiO4, nH2O SiO2 + Impurities +4HF=SiF4 + 2H2O 3 SiF4+ 3H2O= H2SiO3 + 2 H2SiF6 Silicic Acid Hydrofluoro Silicic Acid 1.1 Transfer 0.5 g of the sample to an evaporating dish, moisten with 10 ml of distilled water at room temperature to prevent lumping, add 5 to 10 ml of hydrochloric acid, and digest with the aid of gentle heat and agitation until the sample is completely dissolved. Dissolution may be aided by light pressure with the flattened end of a glass rod. Evaporate the solution to

- 57. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 56 dryness on a steam-bath. Without heating the residue any further treat it with 5 to 10 ml of hydrochloric acid and then with an equal amount of water, or pour at once upon the residue 10 to 20 ml of hydrochloric acid (1 : 1). Then cover the dish and digest for 10 minutes on the water- bath or hot-plate. Dilute the solution with an equal volume of hot water, immediately filter through an ash less filter paper (Whatman No. 40 or its equivalent), and wash the separated silica (SiO2) thoroughly with hot water and reserve the residue. 1.2 Again evaporate the filtrate to dryness, baking the residue in an oven for one hour at 105 to 110°C. Then treat the residue with 10 to 15 ml of hydrochloric acid (1:1) and heat the solution on water-bath or hot-plate. Dilute the solution with an equal volume of hot water catch and wash the small amount of silica it contains on another filter paper. Reserve the filtrate and washings for the determination of combined alumina and ferric oxide. 1.3 Transfer the papers containing the residues to a weighed platinum crucible. Dry and ignite the papers, first at a low heat until the carbon of the filter paper is completely consumed without inflaming, and finally at 1 100 to 1 200°C until the weight remains constant. 1.4 Treat the ignited residue thus obtained, which will contain small amounts of impurities, with 1 to 2 ml of distilled water, about 10 ml of hydrofluoric acid and 2 drops of sulphuric acid and evaporate cautiously to dryness. Finally heat the small residue at 1050 to 1100°C for a minute or two; cool and weigh. The difference between this weight and the weight of ignited sample represents the amounts of silica: Silica percent = 200 (W1 - W2) Where W1 = weight of silica + (insoluble impurities - residue), and W2 = weight of impurities. 1.4.1 To this amount of silica, add the amount of silica recovered from the residue derived from the combined precipitates of alumina and ferric oxide as indicated under 1.5

- 58. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 57 So the total percentage of silica will be = (W1-W2) +W3 ×100 W4 Where W1= Weight of the silica and insoluble impurities W2= Weight of the crucible after hydrofluorization W3=Weight of the silica recovered from iron and aluminium oxide W4=Weight of the sample taken. 1.5 Add 0.5 g of sodium or potassium persulphate to the crucible and heat below red heat until the small residue of impurities is dissolved in the melt. Cool, dissolve the fused mass in water, and add it to the filtrate and washings reserved for the determination of the combined alumina and ferric oxide. % of Fe2O3, Al2O3, CaO and MgO(Gravimetric & EDTA) 2. Fe2O3 (Iron Oxide) 2.1 Method 1 (Potassium Permanganate Method) — To one gram of the sample, add 40 ml of cold water and, while the mixture is being stirred vigorously, add 15 ml of hydrochloric acid. If necessary, heat the solution and grind the cement with the flattened end of a glass rod until it is evident that the cement is digested fully. Heat the solution to boiling and treat it with stannous chloride solution added drop by drop while stirring, until the solution is decolourized. Add a few drops of stannous chloride solution in excess and cool the solution to room temperature. Rinse the inside of the vessel with water, and add 15 ml of a saturated solution of mercuric chloride in one lot. Stir, add 25 ml of manganese sulphate solution and titrate with standard solution of potassium permanganate until the permanent pink colour is obtained. Calculate iron as ferric oxide. 2.2 Method 2 (EDTA Method) Prepare filtrate as given in 1.2 and 1.5. Mix the filtrates and make up the volume in a 250-ml volumetric flask. 2.2.1 Take 25 ml of solution reserved in 2.2 and add dilute ammonium hydroxide (1 : 6) till turbidity appears. Clear the turbidity with a minimum amount of dilute hydrochloric acid (1:10) and add a few drops in excess to adjust the pH to approximately 1 to 1.5. Shake well. Then add 100 mg of

- 59. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 58 sulphosalicylic acid and titrate with 0.01 M EDTA solution carefully to a colourless or pale yellow solution. 2.2.2 Calculation — Calculate the percentage of Fe2O3 as below: 1 ml of 0.01 M EDTA ≡ 0.7985 mg of Fe2O3 Iron oxide (Fe2O3) percent = (.7985*V)/W Where V = Volume of EDTA used in ml, and W = Weight of the sample in g. 3. Alumina (Al2O3) 3.1 Method 1 (Gravimetric Method) — Subtract the calculated weight of ferric oxide and small amount of silica from the total weight of oxides found under 4.4.3. The remainder is the weight of alumina and small amounts of other oxides which are to be reported as alumina. 3.2 Method 2 (EDTA Method) — Take 25 ml of solution reserved under 2.2 and titrate iron at pH approximately 1 to 1.5 with EDTA using sulphosalicylic acid as indicator. Add 15 ml standard EDTA solution. Add 1 ml of phosphoric acid (1 : 3), 5 ml of sulphuric acid (1 : 3) and one drop of thymol blue into the titration flask. Add ammonium acetate solution by stirring until the colour changes from red to yellow. Add 25 ml of ammonium acetate in excess to obtain pH approximately 6. Heat the solution to boiling for one minute and then cool. Add 50 mg of solid xylenol orange indicator and bismuth nitrate solution slowly with stirring until the colour of the solution changes from yellow to red. Add 2 to 3 ml of bismuth nitrate solution in excess. Titrate with 0.01 M EDTA solution to a sharp yellow end point red colour. 4.6.2.1 Calculation — Calculate the percentage of Al2O3 as below: V = V1 - V2 - (V3 × E) Where V= Volume of EDTA for alumina in ml, V1=Total volume of EDTA used in the titration in ml, V2 = Volume of EDTA used for iron in ml, V3= Total volume of bismuth nitrate solution used in the titration in ml, and E= Equivalence of 1 ml of bismuth nitrate solution. 1 ml of 0.01 M EDTA≡0.5098 mg of Al2O3

- 60. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 59 Aluminium oxide (Al2O3) percent = (0.5098*V)/W Where W = Weight of the sample in g. NOTE — Equivalence of bismuth nitrate solution is obtained as follows: Transfer 100 ml of bismuth nitrate solution to a 500-ml flask and dilute with about 100 ml distilled water. Add a few drops of thymol blue solution and ammonium acetate solution until the colour changes from red to yellow. Add 50 mg of xylenol orange indicator and titrate with 0.01 M EDTA solution until the colour changes from red to yellow. The equivalence (ml of EDTA) of 1 ml of bismuth nitrate solution is calculated as follows: E = ----- 100 Where V4 = Volume of EDTA solution in ml. 4. CaO (Calcium Oxide): Method 1 (Gravimetric Method) — Acidify the combined filtrates set aside under 2.2 with hydrochloric acid and evaporate them to a volume of about 100 ml. Add 40 ml of saturated bromine water to the hot solution and immediately add ammonium hydroxide until the solution is distinctly alkaline. Boil the solution for 5 minutes or more, making certain that the solution is at all times distinctly alkaline. Allow the precipitate to settle; filter and wash with hot water. Wash the beaker and filter once with nitric acid (1.33) that has been previously boiled to expel nitrous acid, and finally with hot water. Discard any precipitate (of manganese dioxide) that may be left on the funnel. Acidify the filtrate with hydrochloric acid and boil until all the bromine is expelled. Add 5 ml of hydrochloric acid, dilute to 200 ml, add a few drops of methyl red indicator and 30 ml of warm ammonium oxalate solution. Heat the solution to 70 to 80°C and add the ammonium hydroxide (1 : 1) dropwise, while stirring, until the colour changes from red to yellow. Allow the calcium oxalate precipitate to stand without further heating for one hour, with occasional stirring during the first 30 minutes; filter through Whatmann filter paper No. 42 or equivalent, and wash moderately with cold 0.1 percent ammonium oxalate solution. Set aside the filtrate and washings for estimating magnesia.

- 61. Abhishek Garai (M.Sc Chemistry) NIT Rourkela, Orissa Page 60 4.1 Dry the precipitate in a weighed, covered platinum crucible, char the paper without inflaming, burn the carbon at as low temperature as possible, and finally heat with the crucible tightly covered in an electric furnace or over a blast lamp at a temperature of 1100 to 1 200°C. Cool in a desiccator (to guard against absorption of moisture by ignited calcium oxide) and weigh as calcium oxide. Repeat the ignition to a constant weight. 4.2 Calculation — Calculate the percentage of CaO by multiplying the weight in grams of 200 residue (CaO) by 200 [100 divided by the weight of sample used (0.5 g)] CaO percent = weight of residue × 200 4.3 Method 2 (EDTA Method) — Take 10 ml of solution reserved under 2.2 in a 250-ml concial flask. Add 5 ml of 1:1 glycerol with constant stirring and 5 ml of diethylamine. To this add 10 ml of 4N sodium hydroxide solution and shake well to adjust pH to highly alkaline range of 12 or slightly more. Add approximately 50 ml of distilled water and 50 mg of solid Patton-Reeder’s indicator. Titrate against 0.01 M EDTA solution to a sharp change in colour from wine red to clear blue. 4.4 Calculations — calculate the percentage of CaO as below: 1 ml of 0.01 M EDTA≡ 0.5608 mg of CaO Calcium Oxide (CaO) percent = (.05608×25×V)/W Where V = Volume of EDTA used in ml, and W = Weight of the sample in g. 5. Magnesia (MgO) 5.1 Method 1 (Gravimetric Method) — Acidify the filtrate set aside under 4.1 with hydrochloric acid and concentrate to about 150 ml. Add to this solution about 10 ml of ammonium hydrogen phosphate (250 g/l) and cool the solution by placing in a beaker of ice water. After cooling, add ammonium hydroxide drop by drop, while stirring constantly, until the magnesium ammonium phosphate crystals begin to form, and then add the reagent in moderate excess (5 to 10 percent of the volume of the solution), the stirring being continued for several minutes. Set the solution aside for at least 16 hours in a cool atmosphere and then filter, using