Reviewer for materials engineer

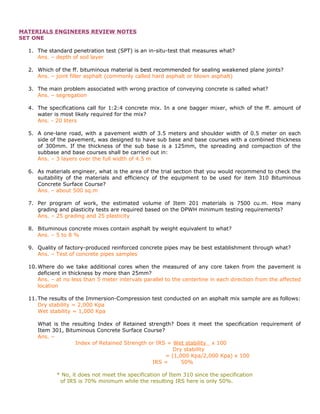

- 1. MATERIALS ENGINEERS REVIEW NOTES SET ONE 1. The standard penetration test (SPT) is an in-situ-test that measures what? Ans. – depth of soil layer 2. Which of the ff. bituminous material is best recommended for sealing weakened plane joints? Ans. – joint filler asphalt (commonly called hard asphalt or blown asphalt) 3. The main problem associated with wrong practice of conveying concrete is called what? Ans. – segregation 4. The specifications call for 1:2:4 concrete mix. In a one bagger mixer, which of the ff. amount of water is most likely required for the mix? Ans. - 20 liters 5. A one-lane road, with a pavement width of 3.5 meters and shoulder width of 0.5 meter on each side of the pavement, was designed to have sub base and base courses with a combined thickness of 300mm. If the thickness of the sub base is a 125mm, the spreading and compaction of the subbase and base courses shall be carried out in: Ans. – 3 layers over the full width of 4.5 m 6. As materials engineer, what is the area of the trial section that you would recommend to check the suitability of the materials and efficiency of the equipment to be used for item 310 Bituminous Concrete Surface Course? Ans. – about 500 sq.m 7. Per program of work, the estimated volume of Item 201 materials is 7500 cu.m. How many grading and plasticity tests are required based on the DPWH minimum testing requirements? Ans. – 25 grading and 25 plasticity 8. Bituminous concrete mixes contain asphalt by weight equivalent to what? Ans. – 5 to 8 % 9. Quality of factory-produced reinforced concrete pipes may be best establishment through what? Ans. – Test of concrete pipes samples 10. Where do we take additional cores when the measured of any core taken from the pavement is deficient in thickness by more than 25mm? Ans. – at no less than 5 meter intervals parallel to the centerline in each direction from the affected location 11. The results of the Immersion-Compression test conducted on an asphalt mix sample are as follows: Dry stability = 2,000 Kpa Wet stability = 1,000 Kpa What is the resulting Index of Retained strength? Does it meet the specification requirement of Item 301, Bituminous Concrete Surface Course? Ans. – Index of Retained Strength or IRS = Wet stability x 100 Dry stability = (1,000 Kpa/2,000 Kpa) x 100 IRS = 50% * No, it does not meet the specification of Item 310 since the specification of IRS is 70% minimum while the resulting IRS here is only 50%.

- 2. 12. Quality Control testing in a DPWH project is the responsibility of the_________? Ans. – Contractor Materials Engineers 13. As materials engineers, when is the right time to start sampling and testing aggregate of the course materials? Ans. – Before the course materials be incorporated in the project. 14. The spot test on asphalt is used to determine what? Ans. – overheating during manufacture 15. Under what climatic condition(s) do we use the lower penetration grade or hard asphalt? Ans. – hot climate 16. Sampling of the freshly mixed concrete should be taken on the ______ batch discharge of the transit mixer? Ans. - middle 17. Soft and unstable soils were encountered during the course of sub-grade preparation. If you were the materials engineer assigned to the project, what is the most effective and cheaper method that you would recommend to stabilize the soil prior to the construction of the subbase course? Ans. - geotextiles 18. How many times per layer should a concrete specimen molded in a 6”x6”x12” beam mold be rodded? Ans. – 63 times 19. What is the basis for acceptance or rejection of any construction materials? Ans. – Materials Test Reports 20. In testing concrete cylinder sample the load applied should be continuous without shock at a constant rate within the range of _______ per second. Ans. - 0.14 to 0.34 Mpa per second or 20 to 50 psi per second. 21. During the application of the first half of the anticipated load a loading shall be permitted. Ans. – higher rate 22. Initial rolling in bituminous mixes shall be performed with a ___________ roller. Ans. – Pneumatic-Tire roller 23. Final rolling in bituminous mixes shall be performed with a ____________ roller. Ans.- 3-wheel or tandem type steel wheel roller 24. Rolling of Bituminous mix shall be discontinued whenever it begins to produce excessive __________or __________. Ans.- pulverizing of the aggregate or displacement of the mixture 25. Final rolling shall be continued until roller marks are eliminated and a minimum _________ mass percent of the density of the laboratory compacted a specimen prepared in accordance with AASHTO T160 has been obtained. Ans. – 95 mass percent 26. Sample from compacted bituminous mix shall be neatly cut by a saw or core drill. Each sample shall be at least ___________. Ans. – 150mm x 150mm x 100mm diameter full depth

- 3. 27. For surface Tolerances the surface (bituminous mix) will be checked by the used of a __________ at sites selected by the engineer. Ans. 3-m straight edge 28. If the volume of coarse aggregate intended in your project in 85 cu.m., how many grading test will you perform? Ans. - 1 grading test 29. What is the most common method adapted by DPWH in the determination of density of the soil in place? Ans. – sand cone method 30. What is the minimum sample for moisture content determination if the maximum size of particles is 50mm (2 inches)? Ans. – 1000 grams 31. What is the minimum mass of field sample for a maximum size of fine aggregates at 4.75mm (no.4)? Ans. – 20 kgs. 32. What is minimum mass of field samples for coarse aggregate with a maximum nominal size of aggregates of 50mm (2 inches)? Ans. – 75 kgs. 33. What is the minimum mass/quality of samples for Portland cement to be tested for quality test in the laboratory? Ans. – 10 kgs. 34. What is the minimum mass/quality of samples for asphaltic materials? Ans. – 5 liters 35. The minimum mass/quantity of samples for asphalt mix? Ans. – 10 kgs. 36. The submission of any type of samples in the laboratory, what should you accomplished and to be submitted together with the samples? Ans. – sample card 37. If the minimum yield strength of a grade 40 steel bars is 40,000 psi, what is the equivalent MN/m2? Ans. – 276 Mpa 38. If the minimum yield strength of a grade 60 steel bars is 414 Mpa, what is the equivalent in PSI? Ans. – 60,000 psi 39. How many samples for quality of steel bars grade 40 if there are 15,500 kgs. of steel bars all 25mm 0 at site? Ans. – 2 samples @ 1 meter long 40. What is the minimum mass of yield samples for coarse aggregates with a maximum nominal size of aggregate of 75mm (3inches)? Ans. – 100 kgs. 41. What is the minimum mass of coarse aggregates retained on the 200mm sieve shall be set a side for sieve analysis for 50mm (2 inches) particle size? Ans. – 2 kgs.

- 4. 42. What is the minimum average strength requirement for non load bearing concrete hollow blocks? Ans. – 4.14 Mpa. 43. What is the minimum average strength requirement for a load bearing concrete hollow blocks? Ans. – 6.9 Mpa. 44. What is the average deficient thickness per lot of cores specimen where no payment is recommended on the project? Ans. – more than 25 mm 45. What is the maximum average deficient thickness per lot of cores specimen where 100% payment is recommended? Ans, - 5 mm maximum 46. Concrete in the area represented by the cores will be consider adequate if the average strength of the cores is equal to at least ________ of the specified strength, f’c and no single core is less than 75% of f’c. Ans. – 85% f’c 47. The weighted loss of fine aggregates subjected to 5 cycles of the sodium sulfate soundness test should not exceed. Ans. – 10 mass % 48. The recommended type of Portland cement to be used in concreting unless otherwise provided for in the special provision: Ans. – type 1 49. Portland cement maybe/shall be rejected if: Ans. - it has partially set - it contains lumps of cake cement - it comes from a discarded or used bag 50. Fine aggregates shall be rejected when if fails in the ________ for organic impurities. Ans. – colormatic test 51. Fine aggregates used for PCCP shall not contain more than ________ of materials passing the 0.075 mm (no. 200 sieve) by washing. Ans. – 3 mass percent 52. The coarse aggregate used for PCCP shall not contain more than ________ of materials passing the 0.075 mm (no. 200 sieve) by washing. Ans. – 1 mass percent 53. The mass percent of wear or abration loss of coarse aggregate used for when by AASHTO T-96 should not exceed. Ans. – 50% 54. The weighted loss of coarse aggregate when subjected to five (5) cycle of the sodium sulfate soundness test should not exceed. Ans. – 12 mass percent 55. The used dowel bars used in PCCP is Ans. – plain round bar 56. A department Order series of 1997 give supplement guidelines on the conduct of Project assessment by the Quality assurance units Regional Office (QAU-RO) Ans. D.O. #52

- 5. 57. A Department Order series of 1997, Revised DPWH Standard specification for Elastomeric bearing pads for bridge superstructures. Ans. – D.O. #20 58. What is the maximum compressive strength of 150 mm x 300 mm concrete cylinder specimen at 28 days for class B concrete? Ans. – 5000 Psi (37.7 Mpa) 59. What is the maximum compressive strength of 150 mm x 300 mm concrete cylinder specimen at 28 days for class C concrete? Ans. – 3000 Psi (20.7 Mpa) 60. The weepholes shall be placed at the lowest points where free outlets for water can be obtained and shall be spread not more than: Ans. – 2 meters center to center 61. One of the most common method used in compaction test/moisture density relation test of soil is: Ans. – AASHTO T-180 62. Which of the ff. common method used in compaction test/moisture density relation test of soil adopted by DPWH: Ans. – AASHTO T-99 and AASHTO T-180 63. If you are to use AASHTO T-99 method (standard proctor test) in compaction test, what is the weight of rammer to be used? Ans. – 2.5 kgs. (5.5 lbs.) 64. Using the standard proctor test or AASHTO T-99, what is the height of drop to a free fall above the elevation of the soil and uniformly distributes such drops to the soil surface? Ans. – 305 mm (12”) 65. Using the standard Proctor test or AASHTO T-99 or moisture density relation test, what is the recommended no. of blows per layer? Ans. – 25 blows 66. Using the modified Proctor test (AASHTO T-180) method for moisture density relation test of soil, what is the recommended no. of blows per layer? Ans. – 56 blows 67. Using again the modified Proctor test ( AASHTO T-180) method for moisture density relation test of soil, what is the height of drop to a free fall above the elevation of the soil and uniformly distributes such drops to the soil surface? Ans. - 457 mm (18”) 68. What is the capacity or the computed volume of mold using 6” (152 mm) mold for both AASHTO T- 99 & AASHTO T-180 method? Ans. – 0.002124 m3 69. What are the data’s needed in moisture density relation test of soil 2 most common method? Ans. – maximum dry density (MDD) - optimum moisture content (OMC) 70. The prime coat shall be left undisturbed for a period of at least ________ hrs. and shall not be opened to traffic until it has penetrated and cured sufficiently so that it will not be picked up by the wheels for passing vehicles. Ans. - 24 hrs.

- 6. 71. Concrete vibrators shall operate at maximum spacing of ________. Ans. – 60 cm 72. Stockpiles of concrete aggregates shall be built-up in layers of not more than in thickness. Ans. – one (1) meter 73. All washed aggregates shall be stockpiled or binned for draining at least ________ hrs. before being batched. Ans. – 12 hrs. 74. Concrete not in place within ________ from the time the ingredients where charged into the mixing drum or that has developed initial set shall not be used. Ans. – 90 minutes 75. Shall not be painted or coated with asphalt or other materials or enclosed in tubes or sleeves. Ans. – tie bars 76. Mortar that is not used within ________ after the water has been added shall be discarded. Ans. – 90 minutes 77. The maximum tensile strength of the wire mesh for gabions shall be Ans. – 586.1 Mpa 78. A wire mesh made of galvanized steel used as a protection works. Ans. – gabions 79. Minimum diameter of gabions per standard specification requirements Ans. – 2.70 mm 80. Determines the hardness and stability of the compacted asphalt pavement Ans. – core test 81. Sampling of PCCP/asphalt core specimens shall be taken from the pavement using: Ans. – core drill 82. Size of asphalt core specimen for thickness and density determination: Ans. – at least 150 mm x 150 mm - 100 mm diameter full depth 83. The diameter of asphalt core specimens shall be at least equal to: Ans. – one and one half times the maximum size of aggregates 84. The thickness of asphalt core specimens shall be at least equal to: Ans. – two (2) times the maximum size of aggregates 85. Obtaining asphalt core specimens for each full days operation shall be: Ans. – at least one but not more than three (3) core samples 86. Determining the thickness of asphalt core specimens is by: Ans. – averaging the four sides of the core samples 87. Bituminous mixture will be measured by: Ans. – tons 88. The average of ________ measures are made on the asphalt core specimens in determining the thickness. Ans. – 4

- 7. 89. In bituminous mixture, ________ will not be permitted as a method of measurement. Ans. – batch weights 90. A core shall be taken for every ________ if no core was taken at the end of each days operation. Ans. – 100 Lm per lane 91. The average of four (4) measurements on the asphalt core specimen is to determine the Ans. – thickness 92. The computation for the quantity of bituminous mixture area the ff. Given: Paving length represented, m = 120 Thickness, cm = 5.0 Width, m = 3.05 Total length of pavement, m= 380 Density, gm/cm3 = 2.221 Ans. – 40.64 tons 93. Main constituents of asphalt which is found in nature or as a residue in petroleum refining. Ans. – bitumen 94. Asphalt is a dark ________ cementations material, solid or semi-solid consistency Ans. – brown to black 95. Sampling bituminous mixes is one (1) sample every: Ans. – 75 cu.m. or 130 m.t. 96. Sampling of asphalt is one (1) sample for every: Ans. – 200 drums or 40 m.t. 97. Sampling of solid asphalt is one (1) sample for every: Ans. – 10 lbs. 98. Representative quantity of one sample in sampling liquid asphalt is ________ sample for every: Ans. – 1 quart to 1 gallon 99. During the breakdown rolling of asphalt mix, it is carried out by: Ans. – pneumatic roller 100. In rolling asphalt mix, what phase of rolling is to remove the marks by the other roller? Ans. – final rolling 101. Ideal composition bituminous aggregates in the asphalt mix. Ans. – 92 % to 96 % 102. The protection of hydrated lime added to the mixture by aggregate basis. Ans. – 0.50 to 1.0 mass percent 103. The mixture of item 231 shall have a mass percent air voids with range of ________. Ans. – 3 to 5 104. A consistency test for solid asphalt that determines the hardness of asphalt. Ans. – Penetration 105. Determines the purity of asphalt on how much bitumen is in the asphalt. Ans. – asphaltane

- 8. 106. The properties of asphalt depend upon this ________ substance which is soluble in petroleum solvents. Ans. – Petrolane 107. Imparts ductility and high break point. Ans. – resins 108. Apparatus used in the Penetration Test of asphalt. Ans. – Penetrometer 109. Apparatus used in the Ductility Test of asphalt. Ans. – ductility machine 110. Apparatus used in Flash Point Test of asphalt Ans. – Cleveland Open Cup 111. The objective is to determine as economical blend between graded aggregates and asphalt in order to produce a pavement that would meet the required specification. Ans. – Job – mix formula 112. Asphalt cement with water and a little amount of emulsifier, usually derivatives of salt. Ans. – Emulsified Asphalt 113. Asphalt cement mixed with kerosene, black in color and liquid and room temperature. Ans. – Medium Curing Cut – back Asphalt 114. Test specimen required for Item 311 – Portland Cement Concrete Pavement. Ans. – Concrete beam 115. Required slump for PCCP, if vibrated. Ans. – 10 to 40 mm 116. Forms for PCCP shall remain in place undisturbed for not less than ________ hrs. after concrete pouring. Ans. – 24 117. Concrete shall be thoroughly consolidated by means of: Ans. – vibrator 118. Flexural strength of PCCP when tested at third point. Ans. – 3.80 Mpa 119. Transverse construction joint is also called as ________ is constructed when there is an interruption of more than 30 minutes in the correcting works. Ans. – cold joint 120. Mixing time of PCCP shall not be less than ________ or more than _______ Ans. – five (5) seconds, ninety (90) minutes 121. Compressive strength of PCCP tested at 14 days. Ans. – 24.1 Mpa 122. Slumps for a workable PCCP if not vibrated Ans. – 40 to 75 mm 123. Depth of weakened plane joints should at all times not be less than _______.

- 9. Ans. – 50 mm 124. Bars placed perpendicular to the longitudinal joint of PCCP. Ans. – tie bars 125. Vibrators shall not be operated longer than ________ in any one location. Ans. – 15 minutes 126. Flexural strength of PCCP when tested at mid-point. Ans. – 4.50 Mpa 127. Sawing of joints of PCCP shall commence as soon as the concrete has hardened sufficiently, usually ________. Ans. – within 24 hrs. 128. The surface of the newly placed PCCP shall be cured for a period of ________. Ans. – 72 hrs. 129. Used as load transfer device and are held in-position parallel to the centerline of the slab. Ans. – dowels 130. Curing compound shall not be applied during ________. Ans. – rain 131. Straw curing on PCCP shall be at least ________ thick which is measured after wetting. Ans. – 20 cm. 132. The finished product of mixing aggregates with cement and water. Ans. – concrete 133. Rate of increase in strength is ________ at high temperature than at low temperature. Ans. – higher 134. Most specifications for concrete exposed to weathering require that water-cement ratio be ________ by weight. Ans. – 0.53 135. Physical property of concrete that withstand deterioration due to exposure to weathering action. Ans. – durability 136. Over sanded and under sanded mixtures require more water in order to be workable, but making it so will, only result in a sacrifice in: Ans. – strength 137. The method commonly used to test on workability of concrete. Ans. – ball penetration test 138. The new method used to test on workability of concrete and these tests are readily made in the field. Ans. – slump test 139. For rich mixes, the strength of ________ is the controlling factor. Ans. – aggregates 140. Strength of concrete is principally dependent on the ________. Ans. – water-cement ration

- 10. 141. Class of concrete that is deposited in water. Ans. – seal 142. Class of concrete used for pre-stressed concrete structure and its member. Ans. – Class “P” 143. Class of concrete used in footings, missive pier shafts and unreinforced or with only a small amount of reinforcement. Ans. – Class “B” 144. Class of concrete used in thin reinforced sections like railings. Ans. – Class “C” 145. Sampling of Portland cement should be done in accordance with AASHTO. Ans. – T-127 146. One (1) Sieve Analysis for every ________ of concrete aggregates or a fraction thereof: Ans. – 1,500 m3 147. A minimum weight of ________ sample shall be taken from each 2,000 bags of cement or fraction thereof. Ans. – 10 kg. 148. Class of concrete used to all superstructures and heavily reinforced substructures. Ans. – Class “A” REVIEW QUESTIONAIRE: 1. What is the dividing line between coarse and fine aggregates? Ans. – 2.00 mm sieve 2. The depth of the weakened plain joint should at all times not less than: Ans. – 50 mm 3. Serves as load transfer device and are held in position parallel to the surface and center line of the slab by a metal device: Ans. – dowel 4. The depth of corrugation in the surface pavement after brooming: Ans. – 1.5 mm 5. The width of weakened joint should not be more than: Ans. – 6 mm 6. The flexural strength of the concrete beam sample at 14 days when tested at third point method: Ans. – 3.8 Mpa 7. What is the weight of class “A” Riprap stones: Ans. – 15 kgs. to a maximum of 25 kgs. with at least 50% weighing 20 kgs. 8. The proportion of mix of mortar for grouted riprap shall be: Ans. – one part of cement to 3 parts of sand

- 11. 9. The practice of artificially densifying and incorporating and incorporating definite density into the soil mass rolling, tampering or other means: Ans. – compaction 10. The unit pressure greater than which progressive settlement will occurs leading o failure: Ans. – bearing capacity 11. Specified or selected materials of designed thickness placed as foundation for pavement. Ans. - base 12. The materials in excavation (cuts) embankment (fills) and embankment foundation immediate below the layer of subbase, base or pavement and to such depth as may effect the structural design: Ans. – sub-grade materials 13. Specified or selected materials of designed thickness placed as a foundation for base: Ans. – subbase 14. A widely used as control test in embankment construction to ensure adequate compaction: Ans. – field density test 15. A sand used to measure the volume of test hole in FDT: Ans. – calibrated sand 16. What item number is Portland Cement Concrete Pavement: Ans. – item 311 17. What are the essential laboratory test for soil classification: Ans. – grading plastic and liquid limit test 18. Provided along the slopes of high embankments as an erosion control measure and to improve the stability of the side slopes; Ans. – berm 19. What is the oven drying temperature for moisture content determination: Ans. – 110 C + 5 20. What is the air drying temperature? Ans. – not to exceed 60ºC 21. The primary quality control mechanism for the production of asphalt mixture: Ans. – job-mix formula 22. The most commonly used method in the design and evaluation of bituminous concrete mixes: Ans. – Marshall Stability Method 23. The most common method in determining the consistency of concrete mix: Ans. – slump test 24. A Department Memorandum Circular, a revised method on FDT: Ans. – DM No. 48 25. Interconnected cracks forming a series of small blocks resembling an alligator’s skin or chicken wire: Ans. – alligator cracks

- 12. 26. A layer of an asphalt aggregate mixture of variable thickness used to eliminate irregularities in the content of an existing surface prior to placement of an overlay: Ans. – asphalt leveling course 27. An application of low-viscosity cutback to an absorbent surface or a mixed-in application of emulsified asphalt. It is used only on untreated base prior to placement of an asphalt pavement. Ans. – asphalt prime coat 28. A thin asphalt surface treatment used to waterproof and improve the texture of an asphalt wearing surface. Ans. - asphalt surface treatment 29. The upward movement of asphalt in an asphalt pavement resulting in the formation of a film of asphalt on the surface. Ans. – bleeding flushing asphalt 30. An application of asphalt materials to any type of road or pavement surface with or without a cover of mineral aggregates that produce an increase in thickness of less than 25mm or 1 inch. Ans. – asphalt surface treatment 31. The localized buckling or shattering of a rigid type pavement occurring usually at transverse crack or joint. Ans. – blow-up 32. A very light application of asphalt applied to an existing asphalt or Portland cement surface, used to ensure a bond between the surface of being paved and the overlaying course. Ans. – asphalt tack coat 33. A mixture of slow setting emulsified asphalt, water, aggregates and mineral filler produce to a slurry consistency and placed on pavement surface. Ans. – asphalt emulsion slurry seal 34. The separation of the pavement due to natural causes, traffic action or reflections from an underlying pavement. Ans. – crack 35. The bowl-shape holes of varying sizes in the pavement, resulting from localized disintegration. Ans. – potholes 36. A crack in asphalt overlay that reflects the crack pattern in the pavement structure underneath. Ans. – reflective cracks 37. The progressive separation of aggregate particles in a pavement from the surface downward or from the edge inward. Ans. – raveling 38. A crack sometimes crescent shaped, that point in the direction of the trust of the wheels on the pavement surface caused by lack of bond between two pavement layer. Ans. – slippage cracks 39. Any condition that might contribute to making a pavement slippery. Ans. – skid hazard 40. The uniform rate of flow of concrete when poured. Ans. – 15 to 20 cu.m. per hour

- 13. 41. Used to evaluate the potential strength of soil aggregate. Ans. – CBR 42. Test used to determine the hardness property of course aggregates. Ans. – abrasion test 43. Test which gives an indication of clay content soil. Ans. – plasticity index 44. The soaked CBR value for Item 200(subbase) at maximum dry density is: Ans. – not less than 25% 45. The soaked CBR value for Item 201(base course) at maximum dry density is: Ans. – not less than 80% 46. The mass percent of wear of course aggregates for base materials by Los Angeles Abrasion Test. Ans. – not more than 50 % 47. The stones used for stone masonry shall have a thickness of not less than: Ans. – 150mm 48. The rate of loading for compressive strength: Ans. – 20-50 psi / sec. 49. The temperature for moist curing of specimen that gives the best result. Ans. – 15.5 C to 37.5 C 50. The maximum size to course aggregates required for Item 311 (PCCP) Ans. – 2 ½ inches (63mm) 51. A program of quality control works to be complied by the contractor is prepared by DPWH. Ans. – quality control program 52. Prescribed in each project based on estimated quantities. The requirements specify the kind and number of test for each item of works. Ans. – minimum testing requirements 53. Memorandum Circular No. hereby directed that all materials men incharge in a said project keep a logbook on materials quality control. Ans. – MC #80 54. A department order hereby directed that only test report issued by the regional/district laboratories of the department and other testing laboratories accredited by the DPWH shall be allowed to be used in the acceptance or rejection of construction materials. Ans. – D.O. # 135 55. A department order, hereby directed, no acceptance and final payment shall be made on completed concrete and asphalt pavements unless core test for thickness determination is conducted. Ans. – D.O. # 119 56. A number of measurements for concrete core specimen. Ans. – 9 57. A number of measurements for asphalt core specimen. Ans. – 4

- 14. 58. A test covers the quantitative determination of bitumen in hot mixed paving mixtures and pavement samples for specification acceptance, service evaluation, control and research. Ans. – extraction test 59. The permitted variations in design requirements of aggregates subbase materials on surface irregularity measured by a 3m straight edge. Ans. – 20mm 60. The permitted variations in design requirements of aggregates base materials on cross fall or camber. Ans. – 0.20% 61. If the required thickness for subbase or base is 150mm or less, this maybe spread and compacted in. Ans. – 1 layer 62. The in-place-density (tested by AASHTO-T-191) of each layer should consistently. Ans. – at least 95% of the MDD 63. The maximum sieve opening for grading requirement of aggregate base course. Ans. 50mm 64. The bituminous prime coat materials should be applied by a pressure distributor at specified temperature and at an application rate ranging from: Ans. – 1 to 2 liters / sq.m. 65. The rate of application for bituminous tack coat materials (item 302) ranging from: Ans. – 0.2 to 0.7 liters / sq.m. 66. The P.I. for mineral filler used for Hot Plant Mix Bituminous Pavement: Ans. – not greater than 6 67. The gradation requirement used for Hot Mix Bituminous Pavement. Ans. – grading d 68. The placing temp. for bituminous mixture measured in the truck prior to dumping. Ans. – should not be less than 107 ºC 69. How many samples or core drilled samples be taken for each days full operation. Ans. – at least one, but not more than 3 70. Unsuitable materials are soils with a liquid limit exceeding. Ans. – 80 71. Unsuitable materials are soils with natural water content exceeding. Ans. – 80 72. Materials containing detrimental quantities of organic material such as grass, roots, sewerage highly organic soils such as peat and muck. Ans. – unsuitable materials 73. The fraction passing the 0.425mm (No.40) sieve for Item 200 shall have a liquid limit of: Ans. – not greater than 35 74. The fraction passing the 0.425mm (No.40) sieve for Item 104 shall have a liquid limit of: Ans. – not greater than 30

- 15. 75. The fraction passing the 0.425mm (No.40) sieve for Item 201 shall have a liquid limit of: Ans. – not greater than 25 76. The fraction passing the 0.425mm (No.40) sieve for Item 202 shall have a liquid limit as determined by AASHTO T-89 Ans. – not greater than 25 77. The fraction passing the 0.425mm (No.40) sieve for Item 200 shall have a plasticity index of: Ans. – not greater than 12 78. The fraction passing the 0.425mm (No.40) sieve for Item 201 shall have a plasticity index of: Ans. – not greater than 6 79. The fraction passing the 0.425mm (No.40) sieve for Item 202 shall have a plasticity index of: Ans. – not greater than 6 80. The coarse portion, retained on a 2.00mm (No.10) sieves for Item 201 shall have a mass percent of wear by the Los Angeles Abrasion Tests as determined by AASHTO – T96. Ans. – not exceeding 50 81. The coarse portion, retained on a 2.00mm (No.10) sieves for Item 201 shall have a mass percent of wear by the Los Angeles Abrasion Tests. Ans. – not exceeding 50 82. The materials passing the 19mm sieves for Item 202 shall have a soaked CBR value tested according to AASHTO T-193. Ans. – 25% minimum 83. The materials passing the 19mm sieves for Item 201 shall have a soaked CBR value tested according to AASHTO T-193. Ans. – 80% minimum 84. The materials passing the 19mm sieves for Item 202 shall have a soaked CBR value of: Ans. – 80% minimum 85. The coarse portion, retained on a 2.00mm (No.10) sieves for Item 202 shall have a mass percent of wear by the Los Angeles Abrasion Tests of: Ans. – not exceeding 4 ASPHALT TECHNOLOGY 1. The primary control mechanism for the production of asphalt mixture Ans. – job-mix formula 2. The most common used method in the design and evaluation of bituminous concrete mixes. Ans. – Marshall Common Method 3. A layer of an asphalt aggregate mixture of variable thickness used to eliminate irregularities in the cement of an existing surface prior to placement of an overlay. Ans. – asphalt leveling course 4. An application of low-viscosity cutback to an absorbent surface, or mixed in application of emulsified asphalt. It is used only on untreated base prior to placement of an asphalt pavement. Ans. – asphalt prime coat

- 16. 5. A thin asphalt surface treatment used to waterproof and improve the texture of an asphalt wearing surface. Ans. – asphalt seal cost 6. The upward movement of asphalt in an asphalt pavement resulting in the information of film of asphalt on the surface. Ans. – bleeding of flushing asphalt 7. An application of asphalt materials to any type of road or pavement surface with or without a cover of mineral aggregates that produce an increase in thickness of less than 25mm or 1 inch. Ans. – asphalt surface treatment 8. The localized buckling or shattering of a rigid – type pavement, occurring usually at transverse crack or joint. Ans. – blow-up 9. A very light application of asphalt applied to an existing asphalt or Portland cement surface, used to ensure a bond between the surface of being paved and the overlaying course. Ans. – asphalt track coat 10. The separation of the pavement due to natural causes, traffic action, or reflections from an underlaying pavement. Ans. – crack 11. The bowl-shape holes of varying sizes in the pavement, resulting from localized disintegration. Ans. – potholes 12. A crack in asphalt overlays that reflects the crack pattern in the pavement structure underneath. Ans. – reflective cracks 13. The progressive separation of aggregate particles in a pavement from the surface downward of from the edge inward. Ans. – raveling 14. A cracks sometimes crescent shaped that point in the direction of the trust of the wheels on the pavement surface caused by lack of bond between two pavement layers. Ans. – slippage cracks 15. Any condition that might contribute to making a pavement slippery. Ans. – skid hazard 16. A department Order, hereby directed, No acceptance and final payment shall be made on completed concrete and asphalt pavement unless core test for thickness determination is conducted. Ans. – DO # 119 17. A number of measurements for asphalt core specimen. Ans. – 2 18. A test covers the quantitative determination of bitumen in hot mixed paving mixtures and pavement samples for specification acceptance, service, service evaluation, control and research. Ans. – extraction test 19. The bituminous Prime Coat materials should be applied by a pressure distributor at specified temperature and at an application rate ranging from Ans. – 1 to 2 liters/m2

- 17. 20. The rate of application for Bituminous Tack Coat materials (Item 302) ranging from Ans. – 0.2 to 0.7 liters/m2 21. The graduation requirement used for Hot Mix Bituminous Pavement Ans. – grading D 22. The placing temperature for Bituminous mixture measured in the truck prior to dumping Ans. – should not be less than 107 ºC 23. How many samples or core drilled samples be taken for each days full operation Ans. – at least one, but more than 3 24. The solvent used to test on residue from distillation at 288ºC of asphalt materials Ans. – trichloroethylene 25. At least three (3) weeks prior to production, the contractor shall submit in writing ________ for each mixture supported by laboratory test data Ans. – job-mix formula 26. Determines the thickness and density of compacted asphalt pavement Ans. – core test 27. Sampling of PCCP/asphalt core specimens shall be taken form the pavement using Ans. – core drill 28. Size of asphalt core specimen for thickness and density determination Ans. – at least 150mm x 150mm (6 in. x 6 in.) 100mm diameter full depth 29. The diameter of asphalt core specimens shall be at least equal to Ans. - four (4) times the maximum size of aggregates 30. The thickness of asphalt core specimens shall be at least equal to Ans. – one and one-half times the maximum size of aggregates 31. Obtaining asphalt core specimens for each full days operation shall be Ans. – at least one (1) but not more than three (3) core samples 32. Determining the thickness of asphalt core specimens is by Ans. – averaging the four sides of the core samples 33. Bituminous mixture will be measured by Ans. – tons 34. The average of ________ measures are made on the asphalt core specimens in determining the thickness Ans. – four (4) 35. in bituminous mixture ________ will not be permitted as a method of measurement Ans. – batch weights 36. The average of four measurements on the asphalt core specimen is to determine the Ans. – thickness 37. The computation for the quantity of bituminous mixture, are the ff: Given: Paving length represented, m = 120.000

- 18. Thickness; cm = 5.000 Width, m = 3.050 Total length of pavement, m= 380.000 Density, gm/cm3 = 2.221 Ans. – 40.64 tons 38. Main constituents of asphalt which is found in nature or as residue in petroleum refining Ans. – bitumen 39. Asphalt is a dark ________ cementations material, solid or semi-solid consistency. Ans. – brown to black 40. Sampling bituminous mixes is one (1) sample for every Ans. – 75 cu.m. or 130 m.t. 41. Sampling of asphalt is one (1) sample for every Ans. – 200 drums or 40 m.t. 42. Sampling of solid asphalt is one (1) sample for every Ans. – 10 lbs. 43. Representative quantity of one (1) sample in sampling liquid asphalt is ________ sample for every Ans. – 1 quart to 1 gallon 44. During the breakdown rolling of asphalt mix, it is carried out by Ans. – steel wheeled roller 45. In rolling asphalt mix, what phase of rolling is to remove the marks by the other rollers Ans. – final rolling 46. A consistency test for solid asphalt that determines the hardness of asphalt Ans. – penetration 47. The properties of asphalt depends upon this _______ substance which is soluble in petroleum solvents as N-phases Ans. – petrolene 48. Imparts ductility high breakpoint Ans. – asphaltine 49. Apparatus used in Penetration Test of asphalt Ans. – Penetrometer 50. Apparatus used in ductility Test as asphalt Ans. – Ductility Machine 51. Apparatus used in Flash Point Test of asphalt Ans. – Cleveland Open Cup 52. The objective is to determine as economical blend between graded aggregates and asphalt in order to produce a pavement that would meet the required specification. Ans. – job-mix formula 53. Asphalt cement with water and a little amount of emulsifier, usually derivatives of salt Ans. – emulsified asphalt

- 19. 54. Asphalt cement mixed with kerosene, block in color and liquid at room temperature Ans. – medium curing cutback asphalt 55. Which kind of Emulsified Asphalt that is negatively charge Ans. – Anionic Asphalt 56. Cutback asphalt can be classified according to each ________. Ans. – viscosity 57. Asphalt cement can be determined or classified by their ________. Ans. – Penetration Grade 58. What kind of asphalt used for joint fillers? Ans. – Blown or Oxidized Asphalt 59. What kind of asphalt that is mixed with a solvent? Ans. – cutback asphalt 60. What physical test that determines if the asphalt is overheated during production? Ans. – spot test 61. What kind of asphalt cement that are commonly used in the Philippines? Ans. – 60 to 70 or 85 to 100 62. What test that will determine if the asphalt is a good binder? Ans. – ductility test 63. Which of the ff. is not an important property aggregates? Ans. – smoothness 64. What property of mix that has the ability to resist deformation form an imposed load? Ans. – stability 65. What property of mix that has the ability to withstand repeated flexing caused by the passage of wheel load? Ans. – fatigue resistance 66. In Marshall Stability Test, which of the criteria not included in determining the average bitumen content? Ans. – flow 67. Specific for Air Voids is ________. Ans. - 3.0 to 5.0 68. Given: Maximum Stability = 6.05 Bulk Specific Gravity = 2.495 Maximum Unit Weight = 5.55 Stability = 1.150 Flow = 5.65 Flow, 025mm = 7.20 Design Air Voids = 5.20 VFA = 75.00 Determine the Optimum Asphalt Content? Ans. – 5.60 69. What property of mix that has the ability to offer resistance to slipping or skidding when mix? Ans. – skid resistance 70. Given: Weight of Sample in Air = 1,188 Weight of Sample in Water = 700

- 20. Weight of Sample in Saturated Dry = 1,230 Specific Gravity of Asphalt = 2.48 Specific Gravity of Aggregates = 2.55 Determine the Bulk Specific Gravity of Mix? Ans. – 2.24 71. Given: Specific Gravity of Asphalt = 1.01 Specific Gravity of Aggregates = 2.72 % Asphalt Content = 7% % Air Voids = 4% Determine the Maximum Theoretical Specific Gravity considering Air Void? Ans. – 2.43 72. What property of mix that has the ability to bend slightly without cracking and to conform to gradual settlement and movements of the base and sub-grade? Ans. – flexibility 73. Mineral filler shall have a plasticity index of not greater than ________. Ans. – 4 74. The prime coat should not be disturbed for at least ________ hrs. and should not be ________ to traffic until it has penetrated and cured efficiency. Ans. – 24 opened 75. Emulsified Asphalt is c colloidal dispersion of asphalt in water. It is ________ colored before use and turns ________ when the emulsion is broken. Ans. – chocolate, black 76. Bituminous materials should fall with what range of tolerance? Ans. – (+/-) 0.4% 77. Temperature of mixture shall have a range of tolerance of ________. Ans. – (+/-) 10ºC 78. Given: Dry Stability = 1,600 Wet Stability = 1,400 Saturated Stability = 1,200 Determine the Index of retained Strength. Ans. – 87.50% 79. What is the initial load employed in stability machine? Ans. – 150 psi 80. What is a small air space that occurs between the coated aggregates particles in a compacted mix? Ans. – Air Voids 81. The compacted pavement shall have a density equal to, or greater than, ________ mass percent of the density of laboratory specimen prepared in accordance with the ________. Ans. – 90- Marshall Stability Test 82. What is the measure of the resistance or measure of distortion of the specimen? Ans. – flow index 83. Given: % of CA, FA, MF respectively = 45, 35, 20

- 21. Sp. Gr. Of CA, FA, MF respectively = 2.75, 2.56, 2.40 What is the specific gravity of aggregates? Ans. – 2.61 84. What do you call the wearing away of the pavement surface caused by the dislodging of aggregate particle? Ans. – raveling 85. The upward movement in an asphalt pavement resulting in the formation of a film of asphalt on the surface _______. Ans. – bleeding 86. What is the longitudinal surface depression of the wheel paths? Ans. – rutting 87. Given: Weight of original sample = 1,140 grams Weight after Extraction = 980 grams Original Weight of filler ring = 30 grams Increase of Weight in filler ring = 30 grams Determine the asphalt content? Ans. – 5.55 88. For the same stretch of road, no core test was conducted at the end of each days operation. Thus, cores were taken for every 100 linear meters of the completed pavement. 100 m 5.3 2.262 100 m 5.1 2.311 100 m 5.1 2.225 100 m 5.2 2.237 100 m 5.0 2.226 What is the quantity? Ans. – 169.72 89. The specimen is tested for stability and flow at ________ ºC as specified in the standard procedure Ans. – 30 ºC 90. In the design of Air Voids, will draw down a line at ________. Ans. – 4.0 91. Which of the ff. is not the component of Asphalt Plant? 92. During asphalt construction, what are the controlled tests? Ans. – extraction test - stability - grading 93. What is the apparatus used to check the temperature of asphalt mix/ Ans. – Armored Thermometer 94. What do you call the localized upward displacement of a pavement due to swelling of the sub-grade or some portion of the pavement structure? Ans. – upheaval

- 22. 95. What do you call the slab movement under passing loads resulting in the ejection of mixtures of water, sand, clay or silt along transverse or longitudinal joints? Ans. – pumping 96. What is the Item number of Bit Concrete Surface Course, 1 lot laid? Ans. - 310 MATERIALS ENGINEERS REVIEW NOTES SET TWO 1. The standard penetration test (SPT) is an in-situ test that measures what? Ans. – depth of soil layer 2. Which of the ff. bituminous material is best recommended for sealing weakened plane joints? Ans. – joint filler asphalt (commonly called hard asphalt or blown asphalt) 3. The main problem associated with wrong practice of conveying concrete is called what? Ans. – segregation 4. The specification call for 1:2:4 concrete mix. In a one bagger mixer, which of the ff. amount of water is most likely required for the mix? Ans. – 20 liters 5. A one lane road, with a pavement was designed to have subbase and base courses with a combined thickness of 300mm. If the thickness of the subbase is a 125mm, the spreading and compaction of the subbase and base courses shabby be earned out in: Ans. – 3 layers over the full width of 4.5 m. 6. As materials engineer, what is the area of the trial section that you would recommend to check the suitability of the materials and efficiency of the equipment to be used for Item 310 Bituminous Concrete Surface Course? Ans. – about 500 sq.m. 7. Per program of work, the estimated volume of Item 201 materials is 7500 cu.m. How many grading and plasticity tests are required based on the DPWH minimum testing requirements? Ans. – 25 grading and 25 plasticity 8. Bituminous concrete mixes contain asphalt by weight equivalent to what? Ans. – 5 to 8 % 9. Quality of factory produced reinforced concrete pipes may be best established through what? Ans. – Test of concrete pipe samples 10. Where do we take additional cores when the measurement of any core taken from the pavement is deficient in thickness by more than 25mm? Ans. – at no less than 5 meter intervals parallel to the centerline in each direction from the affected location 11. The results of the Immersion-Compression test conducted on an asphalt mix sample are as follows: Dry Stability = 2,000 Kpa Wet Stability = 1,000 Kpa What is the resulting Index of Retained strength? Does it meet the specification requirement of Item 310, Bituminous Concrete Surface Course? Ans. – Index Retained Strength or IRS = Wet stability x 100

- 23. Dry stability = (1,000 Kpa/,000 Kpa) x 100 IRS = 50% *No, it does not meet the specification of Item 310 since the specification of IRS is 70% minimum while the resulting IRS here is only 50%. 12. Quality Control testing in a DPWH project is the responsibility of the ________? Ans. – Contractor Material Engineers 13. As materials engineers, when is the right time to start sampling and testing aggregate of the course materials? Ans. – before the course materials be incorporated in the project 14. The spot test on asphalt is used to determine what? Ans. – overheating during manufacture 15. Under what climatic conditions do we use the lower penetration grade or hard asphalt? Ans. – hot climate 16. Sampling of the freshly mixed concrete should be taken on the ________ batch discharge of the transit mixer? Ans. – middle 17. Soft and unstable soils were encountered during the course of sub-grade preparation. If you were the materials engineer assigned to the project, what is the most effective and cheaper method that you would recommend to stabilize the soil prior to the construction of the sub base course? Ans. – geotextiles 18. How many times per layer should a concrete specimen molded in a 6”x6”x12” beam mold be rodded? Ans. – 63 times 19. What is the basis for acceptance or rejection of any construction materials? Ans. – Materials Test Reports 20. In testing concrete cylinder sample the load applied should be continuous without shock at a constant rate within the range of ________ per second. Ans. – 0.14 to 0.34 Mpa per second or 20 to 50 psi per second 21. During the application of the first half of the anticipated load a loading shall be permitted. Ans. – higher rate 22. Initial rolling in bituminous mixes shall be performed with a ________ roller. Ans. – Pneumatic Tire Roller 23. Final rolling in bituminous mixes shall be performed with a ________ roller. Ans. – 3 wheel or tandem type steel wheel roller 24. Rolling of Bituminous mix shall be discontinued whenever it begins to produce excessive ________ or ________. Ans. – pulverizing of the aggregate or displacement of the mixture 25. Final rolling shall be continued until roller marks are eliminated and a minimum ________ mass percent of the density of the laboratory compacted a specimen prepared in accordance with AASHTO T160 has been obtained. Ans. – 95 mass percent

- 24. 26. Sample from compacted bituminous mix shall be neatly cut by a saw or core drill. Each sample shall be at least ________. Ans. – 150mm x 150mm or 100mm diameter full depth 27. For surface tolerances the surface (bituminous mix) will be checked by the used of a ________ at sites selected by the engineer. Ans. – 3 –m straight edge 28. What is the sampling requirement for paving concrete for every 75 cu.m. or fraction thereof. Ans. – one (1) set (consisting of 3 pcs.) concrete beam sample 29. In testing bituminous beam sample for Immersion-Compression Stability is soaked in water bath for ________ days. Ans. – 4 days or 96 hrs. 30. Given: Wt. of dry aggregate = 950g Wt. of asphalt = 50g What is the % of asphalt by weight of total mix? Ans. – Wt. of total mix = wt. of dry aggregate. + wt. of asphalt = 950 g + 50 g = 1,500 g Thereof: (50 g / 1,000 g) x 100 = 5 % 31. Does the percent asphalt in problem #29 meet the required specification for percent asphalt in bituminous mixes? Why? Ans. – Yes, because standard specification for percent asphalt in bituminous mixes is 5% to 8% 32. If the actual percent asphalt in problem #30 is 5% and the percent asphalt in a job-mix formula is 5.6% did it pass the required tolerance? Why? Ans. – No, because the required tolerance for % asphalt in a job-mix formula is 1-0.4%. 33. Which is not the duty or responsibility of a materials engineer? Ans. – quantity of construction material 34. Which is the duty or responsibility of a materials engineer? Ans. – quality of construction material 35. Problems regarding quality of construction materials shall be reported directly by the contractor’s materials engineer to the ________. Ans. – DPWH Materials Engineer 36. How many concrete cylinder sample is required for a 300 pcs. Reinforced Concrete Culvert Pipes (RCCP)? Ans. – 12 sets (consisting of 3 pcs. cone, cylinder per set) 37. If concrete cylinder is not available for a 300 pcs. culvert pipes, how many pipes shall be subjected to test? Ans. – 6 pcs, culvert pipes 38. What kind of test that requires calibrated sand in filling the hole in order to determine the volume of hole? Ans. – Field Density Test (FDT)

- 25. 39. What test that is using a rammer and mold? Ans. – Moisture-Density Relation Test or Compaction Test 40. What kind of asphalt that has a penetration grade of 0 to 30 mm? Ans. – Blown Asphalt 41. If there is a necessary to add water to the concrete mix in order to increase its workability (provide concrete does not exceed specified slump), how many minutes after the initial time of mixing does adding water be permitted? Ans. – not exceeding 45 minutes and that water-cement ration is not exceeded MATERIALS ENGINEERS REVIEW NOTES SET THREE Item 310 – Bituminous Concrete Surface Course, Hot Laid Item 310 consist of constructing a Bituminous Concrete Surface Course composed of Aggregates, mineral filler and bituminous material mixed in a certain plant. 1. What is the % weight of aggregates (coarse, fine and mineral filler) in the mixture of Bituminous Concrete Surface Course? Ans. – 92% to 95% 2. What is the percent weight of asphalt in the bituminous mixture? Ans. – 5% to 8% 3. How can we establish the exact percentage to be used in the bituminous mixture? Ans. – job-mix formula 4. What are the two (2) types of bitumen that are commonly used in bituminous concrete surface course? Ans. – a.) Tar – is a viscous liquid obtained from distillation of coal or wood b.) Petroleum asphalt – are the products of the distillation of crude oil. 5. What are the three (3) major petroleum asphalt products? Ans. – a.) Asphalt Cement – produced in various viscosity grades the most common Penetration grade are 200/300,120/150,85/100,60/70,40/50 b.) Cutback Asphalt – are asphalt mixed with solvents to reduce their viscosity c.) Emulsified Asphalt (Asphalt emulsion) – are mixture of asphalt cement and water with emulsifying agent. 6. What are the solvents for cutback asphalt? Ans. – a.) gasoline for rapid curing (RC) type b.) kerosene for medium curing (MC) type c.) diesel fuel for slow curing (SC) type 7. Emulsified asphalts are either ________ or ________. Ans. – a.) cationic emulsion - which work better with wet aggregates and in cold weather. b.) anionic emulsion – which adhere better to aggregates which have positive charges. 8. What is the bituminous material commonly used in Item 310? Ans. – Asphalt Cement (AC) 9. What greatly influenced the service of an asphalt pavement? Ans. – grade and quantity of asphalt

- 26. 10. What influenced primarily the grade of asphalt selected? Ans. – climatic condition 11. The lower penetration grade or hard asphalt is used in ________? Ans. – hot climate 12. The higher penetration grade or softer asphalt is used in ________? Ans. – cold climate 13. How many weeks do a producer of asphalt mix or the contractor’s shall submit the job-mix formula? Ans. – three (3) weeks prior to production 14. Who will approve the job-mix formula? Ans. – DPWH Project Engineer and Materials Engineer 15. The job-mix formula contains provisions on the ff.: Ans. – a.) grading of aggregates b.) percentage and type of asphalt c.) temperature of aggregates and asphalt d.) temperature of mixture upon delivery or a time of compaction 16. What is the primary quality control mechanism for the production of asphalt mixture? Ans. – job-mix formula which shall conform to the ff. ranges of tolerance: Passing No.4 and larger sieves ± 7% Passing No.8 and No.100 sieves ± 4% Passing No.200 sieves ± 2% Bituminous materials ± 0.4% Temperature of mixture ± 10 ºC 17. What is the minimum dry compressive strength of the mixture? Ans. – 1.4 Mpa ( 200 psi ) 18. The mixture shall have a mass percent air voids with the range of ________? Ans. – 3.0% 19. What is the Index of Retained Strength of the mixture? Ans. – 70% minimum 20. What is the most commonly used method in the design and evaluation of bituminous concrete mixes? Ans. – Marshall Stability Method 21. The quality control tests for asphalt mix are the ff.: Ans. – a.) Immersion Compression Test – determines the Index of Retained Strength of the mix. b.) Extraction and Grading Test – determines the asphalt contains and particle size distribution of coarse and fine aggregates c.) Laboratory Density Test – determines the degree and compaction 22. What is the correct temperature that the mixture shall be placed as measured in the truck just prior to dumping into the spreader? Ans. – 107 ºC 23. When Tar is used, what is the temperature that the mixture shall be placed? Ans. – 66 ºC to 107 ºC

- 27. 24. When the compaction is be done in order to attain the required density? Ans. – when the mixture is still hot and workable 25. What is to be done in order to determine the number of passes that would attain the required density? Ans. – trial section 26. What control during the mixing and compaction is of great significance in the strength of the resulting pavement? Ans. – temperature 27. What kind of roller should be used for the initial or breakdown compaction? Ans. – Pneumatic Tire Roller (not less than 10 tons) 28. For the final compaction and smoothing what kind of roller must be used? Ans. – Tandem smooth wheeled roller (not less than 10 tons) 29. What is the speed of the roller? Ans. – 5 kms./hour 30. How the rolling is be done? Ans. – It should begin from the sides and proceed longitudinally parallel toward the road center line, each trip overlapping one half of the roller’s width. 31. After the final rolling what should be check? Ans. – Degree of Compaction 32. The compacted pavement shall have a density equal to or greater than ________? Ans. – 95% of the laboratory compacted density 33. When the traffic is be permitted to enter the pavement? Ans. – when the pavement has cooled to atmospheric temperature 34. How many samples shall be taken for each full day’s operation? Ans. – at least one but not more than three (3) core samples 35. What is the dimension of the samples taken full depth from the finished pavement for thickness determination? Ans. – 150mm x 150mm or 100mm diameter 36. How is the sample taken form the finished pavement? Ans. – core drill or saw 37. How the surface level of the finished pavement is be checked? Ans. – by the used of 3m straight edge 38. The variation of the surface from the testing edge of the straight-edge between contacts with the surface shall not exceed. Ans. – 6mm 39. What determines the thickness and density of compacted asphalt pavement? Ans. – core test ITEM 311

- 28. 40. What is the strength requirement (Flexural Strength) of a concrete when tested by third point loading method? Ans. – 3.8 Mpa (550 psi) 41. If No, 40 are tested by midpoint method what is the strength requirements? Ans. 4.5 Mpa (650 psi) 42. What is the compressive strength of the PCCP (Portland Cement Concrete Pavement) when tested at 14 days? Ans. – 24.1 Mpa (3500 psi) 43. What is the slump of a workable concrete if not vibrated? Ans. – 40-75mm *if vibrated the slump is 10-40mm 44. What kind of forms are to be used in item 311? Ans. – steel forms and on depth equal to the thickness of the pavement 45. How long shall the forms remain undisturbed after concrete pouring? Ans. – 24 hrs. 46. When concrete is mixed in a central mixing plant how many seconds is the mixing time? Ans. – not less than 50 seconds or more than 90 seconds 47. In transporting concrete what is the time elapsed from the time water added to the mix until the concrete is deposited in place at the site? Ans. – it shall not exceed 45 minutes if hauled in non agitating trucks and 90 minutes when hauled in truck mixers or truck agitators. 48. How is concrete consolidated? Ans. – by the used of vibrator inserted in the concrete vertically 49. How many seconds does the vibrator be operated in one location? Ans. – 15 seconds 50. What kind of sample should be taken on a concrete pavement? Ans. – concrete beam sample 51. How many sets of sample shall be taken from 330 sq.m. of pavement? Ans. – 1 set consisting of 3 concrete beam tests specimens or fraction thereof 52. If the lanes are concreted separately, what kind of joint in a form of key or keyway is used? Ans. – longitudinal construction joint 53. What kind of bars are placed perpendicular to the joint stated in no..52? Ans. – deformed steel tie bars 54. What is the other name of transverse contraction joint? Ans. – weaken planed joint 55. What is the depth of the weaken plane joint when sawed with a concrete saw? Ans. – not less than 50mm 56. The width of the weaken plane joint is ________? Ans. – not more than 6mm

- 29. 57. When is the right time to saw the weaken plane joint? Ans. – within 24 hrs. as soon as concrete has hardened sufficiently 58. What shall be done if cracks appear at or near the joint prior to the time of sawing? Ans. – sawing shall be omitted 59. Tie bars shall not be coated or painted with ________? Ans. – asphalt or other materials 60. What is the metal device that is used as a load transfer device held in a position parallel to the surface and center line of the slab of pavement? Ans. – dowels 61. To protect dowels from corrosion and to facilitate sliding in concrete, it shall be coated with _________? Ans. – thin film of bitumen 62. The surface of the pavement shall be roughened by means of ________? Ans. – brooming 63. What is the depth of the corrugate produced by brooming in the surface of the pavement? Ans. – 1.5mm 64. The surface of the newly placed concrete when it is sufficiently set shall be cured for a period of ________? Ans. – 72 hrs. 65. The curing of the pavement is done on the ff. Ans. – by covering the concrete with mats saturated with water - thoroughly wetting the pavement - by ponding - by applying curing compound immediately after finishing of the surface 66. When the right time is the joint be sealed? Ans. – after the curing period or before it is opened to traffic 67. What is the Item 504 in a DPWH specification? Ans. – Grouted Riprap 68. What is Item 505 in a DPWH specification? Ans. – Stone Masonry 69. What is the difference between Item 504 & 505? Ans. – placement of stone or boulders and the ration of cement and fine sand. 70. What is the ration of fine aggregates to cement number of bags for grout in Item 505 & 505? Ans. – for Item 504, it is 1 part cement 3 parts fine sand (1:3) - for Item 505, it is 1 part cement 2 parts fine sand (1:2)

- 30. MATERIALS ENGINEERS REVIEW NOTES SET FOUR 1. What is the latest state of the art equipment containing a radioactive material which is commonly used in the compaction control of earth and asphalt road construction and in the measurement of moisture content? Ans. – nuclear density gauge (NDG) 2. What is the instrument that is used for examining the quality of rigid materials such as rocks and concrete? (This instrument or equipment is a non-destructive portable instrument with dimensions of 110 x 180 x 160mm and the main uses include the determination of concrete strength (either in-situ or pre-cast0, also to determine the presence of voids, cracks and other imperfections.) Ans. – pundit ultrasonic concrete tester 3. What is the instrument or equipment used for surface test of concrete and asphalt pavements as soon as the asphalt mix has been initially compacted? Ans. – 3-meter straight-edge 4. ________ is an instrument used to measure pavement deflections resulting from vehicle wheel loadings. The results of the elastic deformation tests are used to evaluate the structural conditions of roads, and to help in the design of road strengthening measures and road capacity improvements. Ans. – Benkelman Beam and Deflection Logger 5. ________ is a manually-operated device for deriving a measurement of roughness from the surface profile, which may be expressed in terms of International Roughness Index (IRI) Ans. – MERLIN Road Roughness Measuring Device 6. What is the instrument that is used to pinpoint rebar’s, conduits, pipes, nails and other metals embedded in concrete before cutting or drilling? Ans. – rebar locator 7. ________ is equipment which is used to measure differential deflections between joints of a concrete pavement, to determine the modulus of the existing slabs for use in the design of an overlay, and to estimate the remaining life of an existing pavement. Ans. – falling weight deflectometer 8. ________ is used for the rapid in-situ measurement of the structural properties of existing with unbound granular materials. Ans. – Dynamic Cone Penetration (DCP) 9. In the construction of bridge projects, what is the method used to determine the casting length of the regular piles? Ans. – test piling 10. What is the thinnest cut-back asphalt? Ans. – MC-3,000 MATERIALS ENGINEERS REVIEW NOTES SET FIVE 1. The concrete pavement surface shows high spots of 15mm in a 3-meter straight edge. The concrete in the area represented by these high spots. Ans. - shall be removed and replaced

- 31. * but if high spots being noted exceeds 3mm, but not exceeding 12mm it shall be ground down only. 2. Steel bars placed along longitudinal joints to hold the adjoining slabs together are called: Ans. – tie bars 3. Which of the ff. is authorized to test materials for use in DPWH projects? Ans. – any DPWH – accredited private testing laboratory 4. To check the gradation of aggregates and the asphalt content of laid bituminous concrete mixture, it shall be sampled and tested for: Ans. – extraction test 5. For each full day’s operation, how many asphalt core samples must be taken for thickness determination? Ans. – at least one but not more than three core samples 6. Moisture density relation test determines: Ans. – maximum dry density and optimum moisture content of soil 7. Thickness of in-placed sub-base coarse can be determined by: Ans. – test pitting 8. To determine the optimum moisture content of soil Ans. – moisture density relation test 9. Soil stabilizing agent: Ans. – lime- for silky and clayey soil 10. Type of emulsified asphalt that works better with wet aggregates and cold weather: Ans. – cationic emulsion 11. Water content at which passes form plastic to liquid state. Ans. – liquid limit 12. Another name of hot asphalt. Ans. – asphalt cement MATERIALS ENGINEERS REVIEW NOTES SET SIX 1. Portland cement concrete pavement is what Item in DPWH Spec’s.? Ans. – Item 311 2. Concrete area represented by the cores will be considered adequate if the average strength is equal to? Ans. – 85% of the required strength 3. Lumber is considered as well – seasoned if the moisture content is ________? Ans. – 12 – 18% 4. Soils can be classified according to grain size and plasticity? Ans. – yes 5. Thickness determination for 1km concrete pavement. How many cores shall be taken? Ans. – 5/lane

- 32. 6. The resistance of bituminous mix to moisture damage is determined by ________. Ans. – Index of Retained Strength (IRS) 7. The average compressive strength of a load bearing concrete hollow blocks is ________. Ans. – 1,000 psi 8. Bleeding of asphalt in bituminous surface course means ________. Ans. – over asphalt mix 9. What is the result of over vibration of concrete mix? Ans. – segregation of aggregates 10. What is the corrected measurement for 23.6mm concrete core? Ans. – 23.5mm 11. What are the other terms for particle size analysis? Ans. – sieve analysis - mechanical analysis - grading test/analysis 12. What is liquid-limit? Ans. – it is the lowest moisture content at which the soil will flow upon the application of a very small shearing force 13. The liquid limit is expressed as the moisture content corresponding to what number of blows? Ans. – 25 blows 14. What is plastic limit? Ans. – it is the minimum moisture content at which the soil can be readily molded without breaking or crumbling 15. What kind of water shall be used in laboratory test especially if it deals with chemicals? Ans. – distilled water 16. Liquid limit brass cup with sample is raised and allowed to drop sharply on the base through a height of what? Ans. – 10mm 17. How many rotations per second will the crank of a liquid limit device are rotated? Ans. – 2 rotations per second 18. In doing plastic limit tests to what diameter will the soil thread will begin to break? Ans. – 3.2mm (1/8”) 19. What is the formula for plastic limit? Ans. – PL= (Wa – Wb) / Wb x 100 where:Wa = orig.wt. Crumbled soil thread Wb = wt. of oven-dried crumbled soil 20. What is the Plastic Index (PI)? Ans. – it is the difference between the liquid limit and plastic limit or PI = LL - PL 21. What is specific gravity? Ans. – it is used in a gravimetric-volumetric relationship in soils, (or defined as the ratio of the wt. in air of an equal volume of water at a stated temp.)

- 33. 22. What is the approximate area for density control strips? Ans. – 335 sq.m. 23. What is the maximum depth of roadway embankments per horizontal layer in loose measurement? Ans. – 200mm (8”) 24. What item of work is embankment? Ans. – Item 104 25. What is the kind of material use for Item 200? Ans. – aggregate sub-base course 26. What is the required particle size for selected borrow for topping under Item 104 (embankment)? Ans. – all particle size will pass a sieve 75mm or 3” square openings and not more than 15% mass will pass 0.075mm (No.200) AASHTO T-11 27. P.I. requirement for Item 104 (selected common borrow) is what? Ans. – 6 maximum 28. LL requirements for Item 104 (selected common borrow) are what? Ans. – 30 maximum 29. What is the LL requirement for Item 200 (aggregate sub-base course) passing sieve #40? Ans. – 35 maximum 30. P.I. requirement of materials passing sieve #40 for Item 200? Ans. – 12 maximum 31. Coarse portion retained on sieve #10 (2.00mm) for Item 200 shall have a mass percent of wear by Los Angeles abrasion test of what? Ans. – 50% maximum 32. The required CBR value for Item 200? Ans. – 25% minimum (AASHTO T-180 method D) 33. What is the minimum % field density or degree of compaction for Item 104 (embankment)? Ans. – 95% minimum 34. What is the minimum degree of compaction for Item 200 and 201? Ans. – 100% minimum 35. What is the highest point in moisture density curve of the moisture density relation test or compaction test of soil represents? Ans. – MDD (Maximum Dry Density) and OMC (Optimum Moisture Content) 36. What is the required size of calibrated sand used for Field Density Test? Ans. – any clean, dry, free –flowing, uncemented sand passing #10 and retained #200 sieves 37. What is the degree of compaction of soil having a maximum dry density 2,250 kg./cu.m. and wet density of soil from hole equivalent to 2,335 kg./cu.m. and an average moisture content of 8.85%? % Degree of Compaction = (Dry Density) / Max Dry Density) x 100 Where: Dry Density = Wet Density / (1+MC/100) Wet Density = Wt. of soil filled in hole/volume of hole

- 34. % Degree of Compaction = (1,335) / [1+ (8.85 / 100)] 2.250 = (2,145.15 / 2,250) x 100 = 95.34% 38. Is the soil for No.45 passed the Item 104 requirement for % Degree of Compaction? Ans. – Yes 39. What are the test and number of test needed for 1,800 cu.m. Item 104? G or Grading = 2 P or Plasticity = 2 C or Compaction = 2 D or Density = three in-situ density tests/500 sq.m. 40. What are the test and number of test needed for 2,980 cu.m. Aggregates Base Course (Item 201)? G = 10 P = 10 C = 2 D = three in- situ density tests/500 sq.m. CBR = 2 (1 test for every 2,500 cu.m. or fraction thereof) Q = 2 41. What are the apparatus/materials uses for Field Density Test? Ans. – sand cone, jug (at least 4 liters), guide plate, moisture cans, sand weighing scale, oven with temperature control, chisel, or digging tools, plastic bags and labeling materials (tag name) 42. What is the standard diameter of an orifice in FDT sand cone? Ans. – ½ inch (12.7mm) 43. CHB is tested to determine its moisture content and ________. Ans. – strength 44. Quality of Portland cement sent to the laboratory for testing. Ans. – 10 kg. 45. A set of three beam samples is conducted representing ________ cu.m. of concrete. Ans. – 75 46. Two major components of concrete: select two answers Ans. – paste and mineral aggregates 47. Regardless of use, the grading of aggregates should be: Ans. – uniform 48. The type of Portland cement used in DPWH projects. Ans. – type 1 49. Determines the proportion of the ingredients that will produced concrete of proper workability when fresh and the________. Ans. – Design Mix 50. The maximum permissible water-cement ration for strength of 3,000 psi. Ans. – 0.58 51. The consistency of concrete mixture is determined in the field by: Ans. – slump test

- 35. 52. For every 75 cu.m. of concrete poured, a minimum of ________ cylinder sample are taken in each day of pouring. Ans. – 3 53. When tested at 14 days, the compressive strength of concrete is Ans. – 3,500 psi 54. Forms of concrete pavement shall not deviate from true line by more than ________ at any point. Ans. – 1 cm 55. When hauled in non-agitating trucks, the time elapsed from the water is added to the mix until concrete is deposited in placed shall not exceed ________. Ans. – 45 minutes maximum 56. The depth of the weakened plane joint should at all times not less than Ans. – 50 mm 57. Minimum compressive strength of concrete Ans. – 2,400 psi 58. Transverse contraction joint is also called Ans. – weakened plane joint 59. Vibrators shall not be operated longer than ________ in any one location. Ans. – 15 seconds CONCRETE AGGREGATES AND CONCRETE: 60. How many hours does a fine aggregates tested for specific gravity and absorption be soaked in water? Ans. – 15 to 19 hrs. 61. How to determine if the fine aggregates reaches the saturated surface dry condition? Ans. – it is determine by the use of cone test for surface moisture and if the molded shape of fine aggregates slumps slightly, it indicates that it has reached a surface dry condition. 62. What are the tests required for concrete aggregates? Ans. – a.) Fine Aggregates = grading, specific gravity, absorption, dry unit wt. b.) Course Aggregates = grading, specific gravity, absorption, dry unit wt. and abrasion Note: soundness is also tested as per request. 63. What is the maximum mass % of wear by Los Angeles Abrasion Test? Ans. – 40% maximum 64. What is the required speed of Los Angeles Abrasion Machine per minute? Ans. – 30 to 33 mm 65. What is the size or diameter and weight of cast-iron spheres use in abrasion? Ans. – approximately 46.8 mm diameter and each weighing between 390-455 grams

- 36. 66. What is the required total wt. of sample for abrasion test of coarse aggregate, grading A with 12 numbers of spheres? Ans. – 5,000 grams ±25 grams 67. What is the significance of abrasion test? Ans. – it evaluates the structural strength of coarse aggregates - gives an indication of quality as determined by resistance to impact and wear - it determines whether the aggregates will have degradation during traffic of rolling 68. Quality test for cement is represented by how many bags of cement? Ans. – 2,000 bags or traction thereof 69. What is the sieve use in sieving materials form Abrasion Machine? Ans. – sieve # 12 (1.70mm) 70. Testing machines should be calibrated once every six (6) months if possible but if it is not possible what is the required time should the machine be calibrated? Ans. – once a year 71. Percent tolerance of error in calibrating the machines. Ans. - ± 1% 72. What is the sample for concrete pavement? Ans. – concrete beam sample 73. How many samples should be taken for every 75 cu.m. fresh concrete? Ans. – 3 pcs. sample or 1 set sample 74. What is the sample for structural concrete? Ans. – concrete cylinder sample 75. What is the test use to determine the consistency of concrete? Ans. – slump test 76. How to compute for the slump of concrete? Ans. – slump = height of slump cone – height of fresh cone after subsidence 77. How to compute for the compressive strength of concrete cylinder sample? CS = P A where : P = load, lbs A = area, sq. in A = πD2 = 28.27 in sq 4 78. At what age should a concrete beam sample be tested for flexural test? Ans. – 14 days 79. How to compute the flexural strength of concrete beam sample tested at third Point Loading? R = PL A where: R = modulus of rapture = P (16’) P = load in lbs. of tons 6”x6”x6” L = span length in inches = P B = base in inches 12 A = depth in inches

- 37. 80. What is the minimum flexural strength for third point loading test? Ans. – 3.8 Mpa (550 psi) 81. What is the minimum flexural strength for center point loading test? Ans. – 4.5 Mpa (650 psi) 82. How to compute for flexural strength at center point loading test? R = 3 PL 2 bd2 = 3 P (16) 2 (6) (6) 83. Which part of the batch for fresh concrete should the sample be taken from a stationary mixers, revolving drum truck mixers or agitators? Ans. – two or more regular intervals during discharge of middle portion of the batch 84. What is the size of the tamping rod use in sampling concrete? Ans. – 16mm (5/8 inches) diameter and 610mm (24 inches) long with the tamping end rounded to a hemispherical tip of the same diameter as the rod. OTHER CONSTRUCTION MATERIALS: 85. Concrete masonry (hollow blocks) if subjected to test how many sample is required? Ans. – 6 pcs. / 10,000 units * 12 pcs. if more than 10,000 units 86. What is the strength requirement for loading bearing concrete masonry units? Ans. – individual = 5.5 Mpa (300 psi) minimum average (for 3 samples) = 6.9 Mpa (1,000 psi) minimum 87. How about for non-load bearing concrete masonry units what is the required strength? Ans. – individual = 3.45 Mpa (500 psi) minimum average (for 3 samples) = 4.14 Mpa (600 psi) minimum 88. What is the significance of testing reinforcing steel bars? Ans. – to determine the yield and tensile strength of the bar as well as its elongation and is used to classify the bars into grade 89. What is the required length of RSB for testing? Ans. – 1 meter / 10,000 kgs. / size / shipment 90. What is the significance of bending test for RSB? Ans. – to evaluate the ductile properties of RSB 91. What is the required size of test specimen for G.I. Sheets? Ans. – 60mm x 60mm (3 pcs. from one (1) sheet / 1,000 sheets 92. What is the required sample for paints? Ans. – 1 can (gal. or pail) / 100 cans (gal. or pail) 93. What kind of paint that has a reflectance in the form of beads? Ans. – reflectorized traffic plant 94. What is the common component of house paints? Ans. – pigment and vehicle

- 38. 95. What is this construction material that is dark brown to black cementations material in which the predominating constituents are bitumen? Ans. – asphalt 96. What asphalt is commonly called hot asphalt? Ans. – asphalt cement 97. What is liquid asphalt? Ans. – cut-back asphalt and emulsified asphalt 98. What is the use of blown asphalt or hard asphalt? Ans. – use as joint filler or water proofing 99. SS-I or SS-IH is what kind of asphalt? Ans. – slow setting emulsified asphalt 100. What are the three kinds of emulsified asphalt? Ans. – rapid setting, medium setting, slow setting 101. What asphalt contains water? Ans. – emulsified asphalt 102. What is the penetration grade for blown asphalt? Ans. – 0 to 30 103. What is the ideal penetration grade of asphalt use in tropical regions? Ans. – 85 to 100 (but some uses 60 to 70) 104. Tack coat is use in an existing bituminous of concrete pavement. True or false? Ans. – true 105. What is the rate of application for bituminous tack coat? Ans. – 0.2 to 0.7 L/m2 106. What is the required size of test specimen for G.I. sheets? Ans. – 60 mm x 60 mm (3 pcs. from one (1) sheet) / 1,000 sheets 107. What is the required sample for paints? Ans. – reflector zed traffic paint 108. What is the common component of house paints? Ans. – pigment and vehicle 109. What is this construction material that is dark brown to black cementations material in which the predominating constituents are bitumen? Ans. – asphalt 110. What asphalt is commonly called hot asphalt? Ans. – asphalt cement 111. For how many hours or how long shall a bituminous prime coat left undisturbed? Ans. – 24 hrs. 112. What kind of asphalt is use as prime coat? Ans. – cut-back asphalt (medium curing or rapid curing)

- 39. 113. Bituminous prime coat is use to treat the surface of base course. True or false? Ans. – true 114. No tack coat or prime coat shall be applied when the weather is foggy or rainy. True or false? Ans. – true 115. What kind of asphalt is use as tack coat? Ans. – cut-back asphalt (rapid curing) or emulsified asphalt 116. Where should the bituminous seal coat be used? Ans. – on an existing bituminous surface course with or with out an application of aggregates. 117. If concrete cylinder sample for RCCP is not available for compressive test, one (1) whole piece RCCP for every 50 pieces RCCP will be submitted for quality test. True or false? Ans. – true 118. One set (3 pcs.) concrete cylinder sample shall be taken for every how many pieces of RCCP? Ans. – 25 pieces REVIEW FOR MATERIALS ENGINEERS ACCREDITATION CONCRETE: 1. The most important factor affecting the strength of concrete. Ans. – water – cement ratio 2. As work progresses in a concrete pavement construction sampling of concrete for flexural strength test determination should be taken using: Ans. – beam mold @ 63 strokes per layer 3. In order to determine the consistency of a concrete mixture, the most common method is: Ans. – slump test 4. The strength level of concrete for Item 3.11 will be considered satisfactory if: Ans. – the average of all sets of three (3) consecutive strength test results equals or exceed the specified strength and no individual result is deficiency by 15% of the specified strength. 5. In concrete paving a workable concrete should have a slump of: Ans. – 40-75mm if not vibrated 6. When transporting concrete in a non-agitating truck, the time elapse from the time the water is added to the mix until the concrete is deposited in place at site: Ans. – shall not be exceeding 45 minutes 7. In a concrete paving, 17,680 bags of cement shall be consumed up to its completion, compute for the number of quality test required. Ans. – 9 8. A class B concrete requires a minimum compressive strength of: Ans. – 2,400 psi