Job Safety Analysis For Lifting Activity By Crane | JSA | Gaurav Singh Rajput

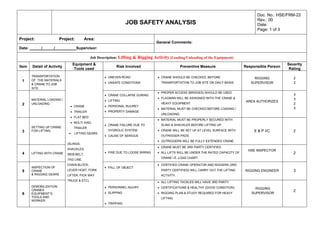

- 1. JOB SAFETY ANALYSIS Doc. No.: HSE/FRM-22 Rev.: 00 Date: Page: 1 of 3 Project: Project: Area: General Comments: Date: / / Supervisor: Job Description: Lifting & Rigging Activity (Loading/Unloading of the Equipment) Item Detail of Activity Equipment & Tools used Risk Involved Preventive Measure Responsible Person Severity Rating 1 TRANSPORTATION OF THE MATERIALS & CRANE TO JOB SITE. • CRANE • TRAILER • FLAT BED • MULTI AXEL TRAILER • LIFTING GEARS (SLINGS, SHACKLES, WEB-BELT, TAG LINE, CHAIN BLOCK, LEVER HOST, FORK LIFTER, PICK WAY TRUCK & ETC). • UNEVEN ROAD • UNSAFE CONDITIONS • CRANE SHOULD BE CHECKED, BEFORE TRANSPORTATION TO JOB SITE ON DAILY BASIS. RIGGING SUPERVISOR 2 2 2 MATERIAL LOADING / UNLOADING • CRANE COLLAPSE DURING • LIFTING • PERSONAL INJUREY • PROPERTY DAMAGE • PROPER ACCESS (BRIDGES) SHOULD BE USED. • FLAGMAN WILL BE ASSIGNED WITH THE CRANE & HEAVY EQUIPMENT. • MATERIAL MUST BE CHECKED BEFORE LOADING / UNLOADING. AREA AUTHORIZES 3 3 2 3 3 SETTING UP CRANE FOR LIFTING. • CRANE FAILURE DUE TO HYDROLIC SYSTEM • CAUSE OF SERIOUS • MATERIAL MUST BE PROPERLY SECURED WITH SLING & SHACKLES BEFORE LIFTING UP. • CRANE WILL BE SET UP AT LEVEL SURFACE WITH OUTRIGGER PADS. • OUTRIGGERS WILL BE FULLY EXTENDED CRANE. E & P I/C 2 4 LIFTING WITH CRANE • FIRE DUE TO LOOSE WIRING • CRANE MUST BE 3RD PARTY CERTIFIED. • ALL LIFTS WILL BE UNDER THE RATED CAPACITY OF CRANE I.E. LOAD CHART. HSE INSPECTOR 2 5 INSPECTION OF CRANE & RIGGING GEARS • FALL OF OBJECT • CERTIFIED CRANE OPERATOR AND RIGGERS (3RD PARTY CERTIFIED) WILL CARRY OUT THE LIFTING ACTIVITY. RIGGING ENGINEER 3 6 DEMOBILIZATION CRANES EQUIPMENT’S, TOOLS AND WORKER. • PERSONNEL INJURY • SLIPPING • TRIPPING • ALL LIFTING TACKLES WILL HAVE 3RD PARTY • CERTIFICATIONS & HEALTHY (GOOD CONDITION). • RIGGING PLAN & STUDY REQUIRED FOR HEAVY LIFTING. RIGGING SUPERVISOR 2

- 2. • ELECTRIC SHOCK • DUE TO POWER LINE • ONLY SINGLE PERSON MUST BE GIVEN SIGNAL TO CRANE OPERATOR. • EMPLOYEES SHOULD BE TRAINED ON SAFE RIGGING TECHNIQUES. • TOOLBOX TALK MUST BE CONDUCTED BEFORE EACH LIFT. • LIFTING AREA SHOULD BE BARRICADED WITH WARNING. • ALL LOADS WILL BE CONTROLLED BY TAG LINES, IF LENGTH IS LONG THAN DOUBLE TAG LINE USED. • LIFTING CREW WILL WORK WITH COMPLETE PPES. • AREA MUST BE CHECKED & FREE FROM ELECTRICAL WIRES BEFORE ASSEMBLING TO THE CRANE. 7 WORK AT HEIGHT SCAFFOLDING CHARRY PICKLES • MATERIAL CAN FALL • PERSONAL FALL • IMPROPER SCAFFOLDING ERECTION • TOOL & JOINTS ETC. SHOULD BE LIFT BY ROPE & BASKET • SCAFFOLDING SHOULD BE ERECTED UNDER SKILLED SUPERVISION. • FULL BODY HARNESS MUST BE WORN WHILE WORK AT HEIGHT 6 FEET & ABOVE. • SCAFFOLDING MUST BE ERRECTED WITH STANDARD & INSPECTED BY SCAFFOLDING INSPECTOR. RIGGING SUPERVISOR SCAFFOLDING INSPECTOR 2 3 3 8 WORK AT NIGHT LIGHTS & STANDS (FLOOD LIGHTS WHITE) • MANUAL HANDLING • SLIP, TRIP & FALL • POOR ILLUMINATION • WORK WOULD BE NEVER ALLOWED IN LESS OR IMPROPERLY DISPRESSED ILLUMINATION/LIGHTS. • ALL WORK AT NIGHT ARRANGEMENT MUST BE DONE BEFORE START OF WORK AT NIGHT. RIGGING SUPERVISOR 2 2 2 9 HOUSEKEEPING WASTE DRUMS SHOPPER BAGS • ENVIRONMENT HAZARD • SLIP, TRIP & FALL • WASTE MATERIAL SHOULD BE STACKED PROPERLY & DUMPED IN DESIGNATED PLACES. • WASTE MATERIAL SHOULD BE BARRICADED. RIGGING SUPERVISOR 1 2 Severity Rating: (1) First Aid / Minor Property Damage (2) Recordable Accident / Property Damage (3) Lost Time Accident / Major Property Loss (4) Catastrophic Accident

- 3. Are you aware of, and do you have the correct PPE? What are the risks? How do controlled risks? _______________________________ __________________________ AREA ENGINEER / SUPERVISOR HSE REPRESENTATIVE

- 4. JSA FOR crane operation Name of the Site : Date of Preparation : JSA Preparation : S.NO SCOPE OF ACTIVITY HAZARD CONTROL MEASURES REQUEST BY 1) Mobile Crane to onsite destination 1) Faults with Crane 2) Plant becoming bogged in sand & mud 3) Pedestrians 4) Onsite Traffic/plant 1) Pre-start Checks 2) Plant to stick to designated roadways and turning areas 3) Personnel on hand to warn others of crane movement in the vicinity or via radio where available. 4) Alternate pathway defined by bollards and reflective tape. EHS SAFETY OFFICER/SECURITY OFFICER 2) Pre-job meeting and Toolbox 1) Inexperienced workers 2) Inadequate consultation 3) Inadequate understanding of equipment 4) Site hazards and emergency Procedures not known 1) Sufficiently skilled employees to complete task (competencies and Licences) 2) Adequate consultation with all relevant employees 3) Adequate competent supervision throughout the project 4) Proper planning for equipment required for the task 5) Site & work area inductions compulsory for all personnel EHS SAFETY OFFICER/SECURITY OFFICER 3) Locate crane into lifting positions on site 1) Pedestrians 2) Traffic 3) Other Plant 4) Other Equipment 5) Buildings Power lines & underground Utilities 6) Lift radius Access 7) Ground Conditions 1) Desired setup area should also be level, 2) unless prior consultation has been made with the supplier of the crane 3) The workplace is adequately prepared for the incoming mobile crane, including where possible a clear predefined area/crane pad for the crane to position upon 4) Check and confirm exclusion areas - Barricades, witches Hats, Danger Tape, Warning Signs 5) Access road are available and soundly constructed with suitable entry points to site 6) Crew should always inspect site prior to positioning crane in final position 7) Elements to observe include 8) Load location and scope of lift 9) Location of any overhead obstructions including wires, trees, buildings, restricted airspace (i.e. near airport) 10) Location of any underground services and/or trenches including utilities and drainage arrangements that may affect integrity of ground 11) Adequate room for rigging and erection of mobile crane 12) Adequate tail (counterweight/winch) swing clearance 13) Ability to cordon off area with suitable barricading resources EHS SAFETY OFFICER/SECURITY OFFICER

- 5. JSA FOR crane operation Name of the Site : Date of Preparation : JSA Preparation : 4) Inspect chains and or slings, shackles, hooks and attachment points in preparation for use 1) Tears in Slings 2) Cracks in chains, shackles, rings and hooks 3) Dropping of load due to faulty 4) lifting gear or faulty attachment points 1) Check slings for rips and tears and remove from service is faults are found 2) Check chains, shackles, hooks and rings for cracks, corrosion, wears, mechanism faults etc and remove from service if faults are found 3) Lifting gear/equipment inspected and tagged with appropriate monthly colour tag 4) Make certain personnel are sufficiently trained with appropriate certificates/ licences 5) Locate crane in lifting position on site – place timbers (pads) and set outriggers 1) Crane overturning due to unstable ground condition 2) Personnel being crushed by outriggers 1) Outriggers must be positioned on a flat surface, 2) Using timbers or suitable material for pads to evenly distribute the load to the ground 3) Crane to be located within the radius for the loads being Lifted. 4) Outriggers should only be extended on the side where the Operator is positioned or with a suitable spotter. 5) Where space permits, outriggers shall always be fully extended 6) Where space is limited, crane should be configured to maximum capacity – this may require the use of reduced outriggers or on rubber; when permitted by the manufacturer 7) Outriggers shall always be extended to manufacturers procedures and specifications, including the requirement to fit manual pins 8) All outriggers-jacks should be utilized at all time 9) Generally Standard Safe Working Load capacity charts are based on all outriggers fully extended and set with wheels clear of ground. 10) Outrigger Packing – 11) Additional packing should always be utilized under outrigger floats 12) Commonly used Outrigger Mats should carry design information and be subject to periodic inspection

- 6. JSA FOR crane operation Name of the Site : Date of Preparation : JSA Preparation : 13) When timber packing is utilized, it should be in a ‘pigsty ‘packing 14) Arrangement ‘Rule of Thumb’ formulae and calculations should be observed; 15) Area (m2) = 0.65 x (Cm + L) ------------- V Cm = Total mass of crane (KN) L = Total mass of load (KN) V = maximum permissible bearing pressure of soil (kpa 6) Attaching Fly or Pin Jib to Crane Working at heights/falling 1) Follow W/H permit use appropriate attachment point & safety harness when walking along crane boom 2) Use an EWP or ladder for this task & follow safe work practices

- 7. JSA FOR crane operation Name of the Site : Date of Preparation : JSA Preparation : 7) Position counterweight truck in an easily accessible spot for the crane to load its counterweights Position counterweight truck in an easily accessible spot for the crane to load its counterweights 1) Plant to be positioned in area clear of obstruction. Roads 2) Traffic control in place if required 3) Once crane is elevated and level, a trial operation should be completed by the operator; this may include 4) Bluffing boom to high angle, and slewing 360 degrees with spotter in position – purpose to review tail swing and outrigger packing suitability 5) Executing ‘dry-run’ where load is required to be picked up and placed – Purpose to ensure crane is capable of task and set required limits 8) Re-assessing Situation throughout job Changes in weather conditions Changes in operators Changes in ground suitability 1) Continual safe operation can be aided by periodic inspection throughout the project of the following; 2) Outrigger Jacks – Leaking oil/retraction of shaft 3) Outrigger Mats – excessive settlement and/or sinking into ground; i.e., loadings increasing beyond estimated capacity of ground – such as unknown back-filling 4) Outrigger Floats – Cracking or critical damage 5) Evidence of water content in ground 6) Should requirements change during operation, then crew shall re-assess and review crane capacity and wider environment to ensure revised work practice is within limits and safe to continue operation

- 8. JSA FOR crane operation Name of the Site : Date of Preparation : JSA Preparation : 9) 10.Packing up and/or leaving crane onsite Unauthorised person access crane site Damage to crane Injury to public 1) Upon completion of project, or specific stage the crane 2) equipment and site shall be left in a secure and safe manner 3) If the crane is to be left onsite; 4) Retract Boom, remove keys from the ignition and secure/lock 5) Outriggers should be inspected prior to next use 6) Barricading should remain in place around the crane and any work area deemed necessary 10) Packing up and cleaning up work site Trip hazards Manual handling injuries Crush & Pinch injuries Equipment damage Counterweights coming off the back of the truck Crush & pinch injuries Falls 1) Use correct manual handling techniques 2) Wear appropriate PPE 3) Rubbish to be placed in bins 4) Tools & Equipment to be packed 5) Lifting gear packed 6) Timbers packed 7) Pads loaded 8) Make certain counterweights are stacked on rubber mats and correctly tied down for trip 9) Guide counterweights onto the truck tray with taglines 10) Where possible use EWP or Platform Ladder Access otherwise be cautious of footing

- 9. JSA FOR crane operation Name of the Site : Date of Preparation : JSA Preparation : 11) Exit site and return to Depot Overhead Powerlines Collision with people/personnel and other vehicles/plant when exiting site Counterweights sliding off during travel Traffic Accident 1) Crane boom to be down when travelling under power lines 2) Maintain site speed limit when exiting work site 3) Communicate with other vehicles onsite is necessary 4) Observe road rules and take into consideration drivers and riders who don’t understand the nature of cranes and trucks.

- 10. CHANGING CONDITIONS & EMERGENCY PROCEDURE: Stop Work, Switch off equipment, Supervisor Direct Personnel to Nearest and Safety Muster Point considering wind direction. Supervisor accounts for all workers. In case of emergency contact 911 / 02-425-0911 Job Safety Analysis PROJECT TITTLE Company: Risk Assessment No: NEW REVISED √ PAGE NO. 1 of 6 Type of Job Being Analyzed Risk Assessment on Lifting Works Department/Section Originate JSA Risk Assessment Team JOB Performers Additional approvals (Determine by Job Supervisor in Correlation with HSE Manager) GENERAL JOB REQUIREMENTS: TBM & PPE Company Representative Name Signature Date 1. Pre task tool box meeting everyday. 2. Personal Protective Equipment 2.1 Safety Shoes with steel toe. 2.2 Safety glasses 2.3 Hard hat 2.4 Hand gloves 2.5 Cover all to workers 2.6 Full body harness on working at heights 2.7 Chin strap for helmets 2.8 Appropriate mask or respirators GS C

- 11. Job Safety Analysis on Lifting Works Task / Activities Initial Risk Initial Risk Rating Control Measures Responsible Residual Risk Rating H M L H M L Doc. No. REV. A Page 2 of 4 1. Work permit Prior to commencing all works, a work permit is required. · Check safety condition of whole area for electrical exposure -Slip, trip, fall during site inspection. -Moving machineries. L • Safe Work Permit and other pertinent documents shall be secured before any works commence. • Pre-start meeting shall be discussed during daily toolbox meeting before work commence. • Equipment and tool inspection must be carried out. • Concerned supervisor / foreman to prepare required safe work plan / permit one day in advance. • Joint Visit of Permit Issuer, Permit Receiver, Supervisor and HSE Officer should be conducted before issuing the Work Permit. • Supervisor / foreman and safety officer to supervise and monitor the activity respectively Supervisor Permit Issuer Permit Receiver HSE Officer L 2. Manpower mobilization -Lack of hazard recognition and awareness of the new workers. - Incompetent and inexperience workers -Lack of training L • Hire competent workers. • Safety induction and training. • Toolbox meeting before work • All workers shall be issued with basic PPE and must wear them on site at all time • Proper supervision and safety coverage • Initial gas testing should be conducted Work Supervisor HSE Officer L 3. Equipment mobilization & Usage of tools & equipment. -Injury of workers (cutting, pinch points, caught in between, struck by flying objects, etc.) - Ergonomics and manual handling. - Moving machineries. L • Inspect before use for qualification. • Defective equip or tool shall not be used. • Regularly check and maintenance. • Implementation of color coding system, • Ensure competent workers with necessary training • Proper usage of PPE. • Following proper procedure on tools & equipment usage. • Proper supervision and safety coverage. Work Supervisor HSE Officer L

- 12. Job Safety Analysis on Lifting Works Task / Activities Initial Risk Initial Risk Rating Control Measures Responsible Residual Risk Rating H M L H M L Doc. No. REV. A Page 3 of 4 4. Transportation of materials Fatality or serious injury -Collision with other vehicles & other properties H • The driver or operator shall be trained or certified for competence. Third Party Certificate or TUV license if necessary. • The flagmen shall be stationed when vehicles reversing • Follow site traffic rule, not overload, shortcut or driving over speed limit of 20km/h. • Ensure to follow Defensive Driving Safety to all drivers and operators. • The equipment, tools or materials on vehicle shall be properly fixed. • Regularly inspect and maintenance. • Ensure to follow Defensive Driving Safety to all drivers and operators. Work Supervisor HSE Officer M 5. Unpacking -unloading and arrangement of materials. -Hand or foot injury (slip, trip & fall hazard) -Ergonomics and manual handling. L • Properly wear correct PPE, including safety gloves and steel-toed shoes. • Handle with care and good position. Proper body positioning while work execution. • Proper coordination with fellow workers. • Proper supervision and safety coverage. Work Supervisor HSE Officer L 6. Lifting, incl. loading and unloading -Personal Injury or Equipment Failure -Tumbling of the crane. -Collision of crane to powerlines & other properties. -Falling of the crane load to workers & other properties. -Strong winds & abnormal weather conditions. -Working or passing of workers to suspended load. H • Check all the equipment or rigging devices to ensure good performance. • Set the barriers around operating area and assign the watchman to keep non-related persons away. • The equipment operator and riggers shall be qualified and certified for competence. (Should have 3rd Party Certification). • Riggers should have designated reflective vest & whistle. • Operate as per the lift instruction and load chart. • Load shall be controlled with taglines during hoisting. • Only rigging devices (sling, chain block, etc.) of correct capacity shall be used for hoisting. • Ground must be even and compacted where the crane is to be positioned. • Ensure that the outriggers are fully extended prior to lift. • Ensure to use proper outrigger pads and proper size. Work Supervisor HSE Officer Rigger Operator M

- 13. Job Safety Analysis on Lifting Works Task / Activities Initial Risk Initial Risk Rating Control Measures Responsible Residual Risk Rating H M L H M L Doc. No. REV. A Page 4 of 4 Risk Assessment Matrix Severity 5 5 10 15 20 25 4 4 8 12 16 20 3 3 6 9 12 15 2 2 4 6 8 10 1 1 2 3 4 5 Risk Rating 1 2 3 4 5 Likelihood • Proper lifting signage must be in place. • Ensure to have lifting plans in all critical lifts activities. • No operation of crane if the wind speed exceeds 32kph or refers to manufacturer’s specification. • No working or passing to the suspended load. • Ensure proper illumination when working at night works. • Beacon lights should be turned on at all times during operation. Please Refer Below for Risk Assessment Rating: Risk Assessment Table Likelihood Severity 1. Highly improbable 1. Minor injury, no time off 2. Remotely possible but known to occur 2. Injury resulting in up to 3 days off 3. Infrequent 3. Injury resulting in 3 or more days off 4. Occasional 4. Major disability injury 5. Frequent and Regular 5. Fatality Likelihood X Severity = Risk Rating Likelihood X Severity Result Equivalent Rating 15 to 25 High Risk H 8 to 14 Medium Risk M 1 to 7 Low Risk L