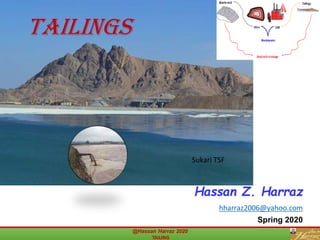

Tailings

- 1. TAILINGS @Hassan Harraz 2020 TAILING Hassan Z. Harraz hharraz2006@yahoo.com Spring 2020 Sukari TSF

- 2. ❑ MINES WASTES: Types of mine waste ❑ WASTE-ROCK DISPOSAL (ROCK DUMPS) ❑ WASTEWATER ❑ TAILINGS & TAILINGS COMPOSITION ➢ Tailings Solids ➢ Tailings waters i) Sulphidic mine wastes ii) Acid Mine Waters ❑ TAILINGS DISPOSAL METHODS ➢ Dynamic Simulation of a Tailing Storage Facility (TSF) ➢ Tailings Dam Styles (or Configurations) ➢ Fundamental Constructed Elements of a Tailings Dam ➢ Water Balance of a Tailings Dams ❑ DISPOSAL METHODS: THICKENED DISCHARGE AND PASTE DISPOSAL IN-PITWASTE DISPOSAL SEEPAGE FLOW TO SURFACE WATER AND GROUNDWATER RIVERINE TAILINGS DISPOSAL SUBMARINE TAILINGS DISPOSAL ❑ ALTERNATIVE LOCATION TO TAILING Outline of Topic:

- 4. ❑ Mine wastes are problematic because they contain hazardous substances that can be (or are) released into the environment around the mine – heavy metals, metalloids, radioactive elements, acids, process chemicals – and therefore require treatment, secure disposal, and monitoring. ❑ Wastes are not only produced during mining, but also at mineral processing plants and smelter sites and include effluents, sludges, leached ore residues, slags, furnace dusts, filter cakes and smelting residues. ❑ Mine wastes may be in the form of: solid waste, water waste, or gaseous waste. ❑ Environmental contamination and pollution as a result of improper mining, smelting and waste disposal practices has occurred, and still occur, around the world (Lottermoser, 2007). 1) MINES WASTES

- 6. 1) MINE WASTES: Open-pit mining Underground mining Produces waste rock: either ➢Barren Host Rock , or ➢ “Ore” that is too low-grade, overburden soils and sands. Mineral processing Hydrometallurgy ▪ Produces processed solid wastes that includes: tailings and sludges with different physical and chemical properties. ▪ Tailings can be used as mining back-fill, but are generally contained on surface. ▪ Also produces mill-water and other processing waste-water also produced, as well as atmospheric emissions.

- 7. ❑ Waste-rock is always produced at an open pit mine and rarely, if ever, produced at an underground mine. ❑ “Waste-rock” is rock emerging from the mine that will not be processed further. It is either “ore” that is below the cut-off grade, or is simply the barren host-rock to the mineral deposit. ❑ Rock dumps contain an wide variety of different rocks and minerals that is site specific, depending on the nature of the ore deposit and the host-rock. If sulphide minerals are present in any of the rocks, there is the potential for Acid Mine Drainage. ➢ Generally rock dumps are not sealed at their base, and the risk of acid water incursion into the surface drainage system or subsurface aquifers is very high. ❑ Dumping must be managed because uncontrolled dumping can be dangerous. ✓ Water flowing through a dump must also be controlled to maintain stability and prevent contaminating surface water or groundwater. ✓ Rock dumps are also highly porous to water flow, and therefore increases significantly the risk of AMD production. ❑ The operation and management of a waste dump are affected by the mine plan, i.e., the geometrical relationship between waste and ore in the mine and the strip ratio. 2) WASTE-ROCK DISPOSAL (ROCK DUMPS)

- 8. Trucks (the size of houses) dump 200-ton loads of waste rock from an open pit mine in Nevada. A composite storage approach is used here: top-down dumping is following after an earlier phase of bottom-up dumping. http://science.nationalgeographic.com/science/enlarge/dumping-waste-rock.html Rock dumpsTop-down storage: waste rock is dumped over an advancing face. Bottom-up storage: waste rock is dumped in a series of piles, and later spread out and flattened, to be covered by the next layer of dumping.

- 9. Typically a “plume” of contaminated water (either acidic or not) and precipitated waste products is developed below and around a rock dump. Schematic cross-section of a sulphide waste dump showing a plume of acid water seeping into the ground. Also shown is how various subsurface minerals (at this particular site) help to buffer, or neutralise, the acid. The initial highly acidic pH value of 1, directly below the dump, is buffered back to a neutral pH value of 7 at some depth below the dump. Figure from Lottermoser, 2007, reproduced from Jurjovec et al., 2002. Potential for lateral migration of contaminated or acidic water within subsurface aquifers 2) WASTE-ROCK DISPOSAL (ROCK DUMPS)…..(Cont.): Sulfidic waste

- 10. ❑ Tailings consist of a Liquid and Solid Component: generally about 20 – 40 weight percent solids (Robertson, 1994). ✓The composition of both is highly site-specific, depending on the ore and gangue minerals and the nature of the water (fresh or saline) and processing chemicals used. i) Tailings waters may be Alkaline (Cyanide used in processing), Acidic (Sulphuric Acid used in processing) or Saline (Saline Water used in processing). They are a complex cocktail of residues of the processing chemicals. The waters are highly chemically reactive. ii) Tailings solids are: ✓finely ground rock from the mill ✓particles ≤ 0.1 mm in diameter (sand and silt) 3) TAILINGS & TAILINGS COMPOSITION

- 11. 3.1) Solid Tailings ❑ In mining and mineral processing, materials are separated according to their particle size and mineralogy ❑ The wastes produced fall into ➢ Coarse-grained (waste/rejects); & ➢ Fine-grained (tailings) ❑ Tailings: ➢ Rock flour resulting from the crushing and or grinding of mine ore ; ➢ Finely ground rock from the concentrator/processing plant. ➢ Particles ≤ 0.1 mm in diameter (sand and silt). ❑ Conventionally disposed of separately Co-disposal involves the combining of these waste streams Figure from Lottermoser, 2007. GRAIN SIZES OF SOLIDS

- 12. 3.2) Waste Water (or Liquid Waste) ❑ Waste water consists of liquid wastes from processing: ➢Flotation Reagents, SX/EW solvents and ➢Acids or Cyanide used in leaching processes: ✓Alkaline (Cyanide used in processing), ✓Acidic (Sulphuric Acid used in processing) or ➢Saline (Saline Water used in processing). ❖They are a complex cocktail of residues of the processing chemicals. The waters are highly chemically reactive. ❑ Waste water from a mine may contain: ➢ ammonia from explosives ➢ contaminated groundwater ❑ Something has to be done about waste water. The best strategy is to minimize the production of waste water but this usually leads to higher costs. It could be contained, as in behind a dam, but this is difficult and risky. Usually it is treated and reused or discharged to the environment.

- 13. ❑Sulphide wastes are the biggest problem on mines because of potential for generating acid mine waters. Pyrite is the major concern. ❑Sulphide minerals occur abundantly in many types of deposits: ❖ Metallic ore (Cu, Pb, Zn, Au, Ni, U, Fe) ❖ Phosphate ores ❖ Coal seams ❖ Oil shales ❖ Mineral sands ❑Sulphide minerals may be exposed (just about) everywhere in mines: ❖ Tailings dams ❖ Waste rock dumps and coal spoil (overburden) heaps ❖ Heap leach piles ❖ Run-of-mine and low-grade ore stockpiles ❖ Waste repository embankments ❖ Open-pit floors and faces ❖ Underground workings ❖ Haulroads and road cuts i) Sulphidic Mine Wastes:

- 14. “Acid mine drainage” (AMD) refers to a particular process whereby low pH mine water is formed from the oxidation of sulphide minerals. It provides one of the most significant hydrological impacts of mining. AMD is particularly prevalent in both metallic mineral and coal mines. Some authors refer to “Acid rock drainage” (ARD), “Acid sulphate waters” (ASW); and also “Acidic ground water” (AG) when referring to impacted ground-water specifically. ii) Acid Mine Waters:

- 15. ❑ Tailings are (generally) stored in engineered structures or impoundments, called “Tailings Storage Facilities” (TSF) or “Tailings Dams” (TD). ➢ It is estimated that there are at least 3,500 tailings dams worldwide (Davies and Martin, 2000). ❑ Tailings dams (TD) should be constructed to: ➢Contain waste materials indefinitely, and provide long term stability against erosion and mass movement. ➢Achieve negligible seepage of tailings liquids into ground and surface waters to prevent contamination of these waters. ➢Prevent failure of dam structures. ❑ The overriding issue with tailings dams is getting the liquid out of them, safely, both during mining and afterwards. ❑ In an alternative disposal approach (that is often highly criticised), no impoundment is used at all, and tailings are pumped directly into rivers (Riverine Tailings Disposal), lakes (Lacustrine Disposal) or into the ocean and onto the seafloor at some water (Submarine Tailings Disposal – STD). 4.2) Tailings Disposal Methods ..(Cont.)4) TAILINGS DISPOSAL METHODS

- 16. 4) TAILINGS DISPOSAL METHODS ….(Cont.)

- 17. 4.1) Dynamic Simulation of a Tailing Storage Facility (TSF)

- 18. 4.2) Tailings Dam Styles (or Configurations)

- 19. Tailings dams hold up to several hundred million cubic meters of water saturated tailings – they can be very, very large structures. ❑ The fundamental constructed elements of a tailings dam are: ➢ Dam walls (dykes) to contain the tailings. These are normally constructed using waste rock and material available at the dam site. The maximum wall height is reported currently to be about 100 m. ➢ Impermeable liners at the base of the dam to prevent leakage of fluids. Linings may consist of geomembranes (polyethylene or PVC), or clay layers, or a combination of the two. ➢ Drainage ditches around the periphery of the tailings dam to collect seepage. ➢ Under-drains to facilitate drainage and consolidation of the tailings in the dam. (Not all tailings dams have under-drains installed). Without under-drains, tailings dams can only dry-out by evaporation and seepage, which generally takes a long time (years after mining has ceased). 4.3 ) Fundamental Constructed Elements of a Tailings Dam

- 20. Tailings dam at Chatree Gold Mine (Thailand) shortly after commissioning, showing under-drains installed in a herring-bone pattern. Under-drains significantly improve water drainage from the tailings dam, thereby reducing water saturation of tailings sediments and improving geotechnical strength and safety of the dam. Figure from Spitz and Trudinger, 2009. (i) drains beneath the dam walls, (ii) double liners under the dam, with a leak detection system between layers, (iii)under-drains at the base of the tailings and a liquid recovery system. Best practice tailings dam construction will consist of: 4.3 ) Fundamental Constructed Elements of a Tailings Dam….(Cont.)

- 21. Mature, but active, tailings dams located south of Johannesburg, South Africa. These dams are receiving the final tailings products of the reprocessing of numerous old mine- dumps spread around Johannesburg. The mines were closed in the 1960s. http://www.panoramio.com/photo/2399572 4.3 ) Fundamental Constructed Elements of a Tailings Dam…(Cont.)

- 22. 4.3 ) Fundamental Constructed Elements of a Tailings Dam…(Cont.)

- 24. 4.3) Fundamental Constructed Elements of a Tailings Dam…(Cont.)

- 25. 4.4) Water Balance of a Tailings Dams

- 26. Thickened Tailings Figure 1: Thickened discharge at Kidd Creek, ON, Canada (left) and at Mt Keith, Western Australia (right)

- 27. 5) THICKENED DISCHARGE AND PASTE DISPOSAL PLAN VIEWAIR-PHOTO Thickened tailings are discharged from central “riser” and a series of outer risers to create a set of cone shaped impoundments. The “risers” are moved up incrementally as the layers of tailings material build up. Figure is greatly vertically exaggerated: the slope of “beaches” is only 1 to 3 1 – 3 Figure from Spitz and Trudinger, 2009.

- 28. See e.g., Williams and Seddon, 1999; Brzezinski, 2001. Advantages over conventional tailings disposal are that: (i) The disposal site covers a much smaller surface area, (ii)tailings are not segregated into coarse and fine components, which improves the geotechnical properties of the pile, (iii)water consumption is significantly reduced, (iv)process chemicals are recovered with the water, rather than left with the tailings, (v)contaminated water drainage into the subsurface and surface water systems is reduced, (vi)The resulting cone shaped deposit provides an attractive landform (say the miners!), more amenable to rehabilitation. Disadvantages of the method include: (i) The operations are subject to dust generation, (ii)failure due to liquefaction is not ruled out entirely during the period required to dry the paste (McMahon et al., 1996). Thickened discharge disposal – advantages and disadvantages:

- 29. 29 Example Thickened tailings deposited into pit pond Waste rock end-dumped into pit

- 31. hharraz2006@yahoo.com TSF View of Sukari Pit Disposal Tailings Waste rock Tailing beach

- 32. hharraz2006@yahoo.com Sukari Pits Disposal Tailings 32 Thickened tailings Waste TSF TSF TSF

- 33. hharraz2006@yahoo.com General view of Sukari mine site Waste TSF TSF

- 35. Figure 1: Typical in-pit tailings storage

- 36. SEEPAGE FLOW TO SURFACE WATER AND GROUNDWATER Seepage to surface water and groundwater may lead to surface water and groundwater contamination in the short- medium- and long- term. The facility needs to be adequately located and designed and the relevant seepage control measures need to be in place according to the characteristics of the managed tailings in order to minimize contamination of surface and groundwater. Figure illustrates schematic seepage flow scenarios for different types of tailings facilities.

- 37. ❑ Riverine tailings disposal is currently used in more than a few modern mining projects, e.g., the copper mines at: ➢ Grasberg-Ertsberg, Indonesia ➢ Porgera, Papua New Guinea ➢ Ok Tedi, Papua New Guinea ➢ Bougainville (closed), Papua New Guinea ❑ Riverine disposal is “preferred” in these areas because earthquakes, land-slides and very-high rainfall makes the construction of tailings dams geotechnically “impossible”. ❑ Miners argue that high natural sediment loads in rivers, generated by the high rainfall, is able to dilute the mine tailings discharges. (Nonsense – tailings volumes are huge compared to the natural sediment load). ❑ Tailings can be neutralized before disposal into the river systems (but they are not always). ❑ Historically: riverine tailings disposal from mines was commonly practiced. 7) RIVERINE TAILINGS DISPOSAL:

- 38. ❑ The solids and liquids of tailings are transported down rivers for considerable distances: tens to hundreds to thousands of kilometers. ❑ Sulphide minerals in discharged tailings generally oxidize in oxygenated river waters, creating the potential for acidification of waters. ❑ Problems include: ➢ Significantly increased sedimentation and turbidity in the river system, and associated flooding of lowlands. ➢ Contamination of the stream and floodplain sediments with metals, and associated impact on aquatic ecosystems. ➢ Diebacks of rainforests and mangrove swamps. 7.1) Riverine tailings disposal – impacts:

- 39. 8) SUBMARINE TAILINGS DISPOSAL Figure from Spitz and Trudinger, 2009. Greater than 50 m water depth De-aeration and mixing with seawater to increase density of slurry Coagulants and flocculants used to bind particles together to form a thicker mixture to prevent wide dissemination of the tailings-plume underwater Plume of lighter tailings material Final resting place of tailings on the sea-floor The euphotic layer is defined as the depth reached by only 1% of photosynthetically active light (High density polyethylene)

- 40. ALTERNATIVE LOCATION TO TAILING

- 41. Follow me on Social Media http://facebook.com/hzharraz http://www.slideshare.net/hzharraz https://www.linkedin.com/in/hassan-harraz-3172b235 @Hassan Harraz 2020 TAILINGS