Design,Analysis & Fabrication of suspension of all terrain vehicle

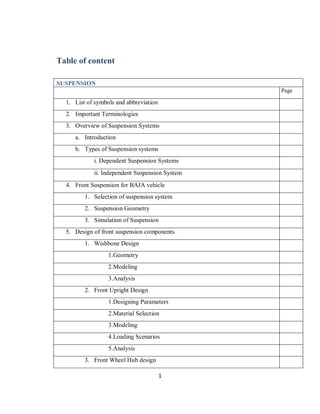

- 1. 1 Table of content SUSPENSION Page 1. List of symbols and abbreviation 2. Important Terminologies 3. Overview of Suspension Systems a. Introduction b. Types of Suspension systems i. Dependent Suspension Systems ii. Independent Suspension System 4. Front Suspension for BAJA vehicle 1. Selection of suspension system 2. Suspension Geometry 3. Simulation of Suspension 5. Design of front suspension components 1. Wishbone Design 1.Geometry 2.Modeling 3.Analysis 2. Front Upright Design 1.Designing Parameters 2.Material Selection 3.Modeling 4.Loading Scenarios 5.Analysis 3. Front Wheel Hub design

- 2. 2 1.Introduction 2.Wheel bearing Selection 3.Designing Parameters & Considerations 4.Modeling 5.Loading Conditions 6.Analysis 4. Stub Axle design 1.Designing Parameters & Considerations 2.Modeling 3.Analysis & Material Selection 6. Rear Suspension for BAJA vehicle 1. Selection of suspension system 2. Suspension Geometry 3. Simulation 7. Design of rear suspension components 1. Trailing Arm & Rear upright design 1.Geometry 2.Designing parameters & Modeling 3.Analysis 2. Rear Wheel Hub design 1.Introduction 2.Wheel bearing Selection 3.Designing Parameters & Considerations 4.Modeling 5.Loading Scenarios 6.Analysis 8. Fabrication of Front Suspension Components

- 3. 3 1. Wishbones 2. Front Uprights 3. Front Wheel Hubs 4. Stub axles 5. Trailing arms 6. Rear uprights 7. Rear wheel hubs STEERING 9. Introduction to Steering System 10. Types of Steering Gearboxes 11. Design of Steering System 1. Steering geometry 2. Collapsible Steering Assembly 12. Fabrication of Steering System 13. Summary 14. Bibliography

- 4. 4

- 5. 5 1. Units Used Steering Effort Fst N Braking torque Tb N-m Radius of brake disk rb M Cornering Force Fcorner N 2. Important terminologies 1. Upright: the component that holds together the suspension control arms to the tyre of the vehicle, the upright accommodates the upper and lower ball joints. It allows for the pivotion of the tyre to perform steering action, the upright only pivots about its axis, and moves in a vertical path tracing the tyre. 2. Hubs: The hubs are the rotating components that allow for the rotation of the tyre, they are placed on the stub axle or live axle, usually supported by wheel bearings, these hubs carry the rim along with the tyre and in most cases the brake rotors. 3. Stub axle: it is an integral part of the upright, it is an extension from the knuckle that will eventually be used to carry the hub, the stub axle is a replacement for a live-axle. 4. Mounting tabs: These are plates that are welded on to the frame, with the required provision for bolting the suspension components such as wishbones and the shock absorber. They are positioned according to the required suspension geometry. 5. Shock absorbers: The primary damping components used in a vehicle to allow the dissipation of energy absorbed by the tires during motion, which may be bump force or any other form of shock loading. Shocks control spring motion, that is, they slow down and reduce the magnitude of the spring’s oscillation. The process

- 6. 6 is known as damping. In technical terms, a shock controls the frequency and amplitude of the suspension's oscillation. In layman’s terms, a shock controls how fast and how much the suspension compresses and rebounds. 6. Wheel rate: is the actual rate of a spring acting at the tire contact patch. This value is measured in lbs/inch or N/mm. 7. Suspension frequency: refers to the number of oscillations or "cycles" of the suspension over a fixed time period when a load is applied to the vehicle. 8. Ductility: In materials science, ductility is a solid material's ability to deform under tensile stress; this is often characterized by the material's ability to be stretched into a wire. 9. Finite Element Methods: The finite element method (FEM) is a numerical technique for finding approximate solutions to boundary value problems for differential equations. It uses vibrational methods to minimize an error function and produce a stable solution. Analogous to the idea that connecting many tiny straight lines can approximate a larger circle, FEM encompasses all the methods for connecting many simple element equations over many small sub domains, named finite elements, to approximate a more complex equation over a larger domain. 10. Hardness: Hardness is a measure of how resistant solid matter is to various kinds of permanent shape change when a force is applied. Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, and viscosity. 11. Hardness number: A number representing the relative hardness of a mineral, metal, or other material as determined by any of more than 30 different hardness tests such as Brinell hardness number, Rockwell hardness number. 12. Endurance Limit: The maximum stress that a material can withstand for an infinitely large number of fatigue cycles; maximum cyclic stress level a metal can withstand without fatigue failure. See also fatigue strength. 13. Bore: In terms of machinery bore is a process of enlarging a hole to a precise diameter with a cutting tool within the hole by rotating either the tool or the work piece.

- 7. 7 3. Overview of Suspension Systems 3. 1 Introduction Vehicle dynamics is concerned with two aspects of the behavior of the machine. The first is isolation and the second is control. It is a study of the behavior of the vehicle in a dynamic state. Chart reference: Multi-body systems approach to Vehicle dynamics by Mike Blundell and Damian harty. The most important constituents of vehicle dynamics are given below with a brief explanation.

- 8. 8 Isolation: The process of separating the driver from disturbances occurring as a result of vehicle operation. It is evident that there are two major types of disturbances, external which are due to factors outside the vehicle system and mostly beyond the control of the driver such as aerodynamics, which is weight gain, lift etc, road factors speak about the road nature, roughness etc, internal factors constitute the vibrations due to engine and transmission components etc. The behavior of the vehicle in response to road undulations is referred to as ‘ride’ and could conceivably be grouped with refinement, as the ride of the vehicle can be tuned to achieve a desired effect. Control: response of the vehicle to driver demands. The driver continuously varies both path curvature and speed, subject to the limits of the vehicle capabilities, in order to follow an arbitrary course. Speed variation is governed by vehicle mass and tractive power availability at all speeds on different types of terrain. The suspension of an automobile is a system that consists of mechanical components that are designed to fit in a preferred geometry, being able to handle the effects of road irregularities or dynamic characteristics. The primal objectives of the system are ● To be able to locate all the four wheels of the vehicle ● To be able to maintain the required ride height (ground clearance) ● To provide a stable and comfortable ride and handling ● To provide road contact, even in inhospitable terrain. This thesis is about the designing process and fabrication methods involved for an all- terrain vehicle that has been designed and manufactured to compete in the BAJA SAEINDIA 2014 competition. Designing suspension system for any car requires technical knowledge in several disciplines such as design of machine members, kinematics and geometry. The geometry essentially means the board subject of how the unsprung mass of the vehicle is connected to the sprung mass. These connections or links dictate the path of motion and also control the forces that are transmitted between them. A suspension geometry must be designed to meet the requirements or ideals of the vehicle to be built, a lot of factors must be taken into consideration such as the ride height, the travel, the spring rates etc.

- 9. 9 Usually the chassis or the frame of the vehicle needs to be modified or designed according to the suspension system, hence one setup cannot be used elsewhere. There is no single best geometry. Apart from the basic objectives a few vehicle specific suspension objectives have been made to design the suspension for the all-terrain BAJA vehicle, they are: ● Large suspension travel ● Adjustability, to tune the suspension. ● Good ground clearance. ● Simple and lightweight construction. Every suspension setup is an assemblage of control arms, shock absorbers, uprights, axles and tyres which are laid out in a way to do their part, quietly in the background as the vehicle is put to all types of loads. The design of this system gets complex in way because, while being restricted ( controlled ) in their motion path by the control arms, the wheel will have camber, caster and toe change. Therefore sometimes just links or control arms are not sufficient to provide a good suspension characteristic. In such a scenario various components such as toe link, camber link, shock absorber mounting become extremely important. The suspension design has been done in a phase-wise manner to ease up the task and to provide better flexibility of the results and also to allow for modification of the design if there may be a need. Phase 1: Determination of geometry to be used and the type of setup to be used Considerations made during Phase 1 were: ● Independent nature. ● Comply with rule book track width of 64”. ● Smaller packaging. ● Fabrication limitations. ● Weight reduction. Phase 2: Determination of spring and damper system. Considerations made during Phase 2 were: ● Motion Ratio

- 10. 10 ● Installation Ratio ● Spring rates ● Damping characteristics ● Weight of the Spring-Damper system ● Initial compression of spring ● Ride frequency In this regard, various other parameters which are explained in later chapters have also been taken care off, some of them being, position of roll centre, minimization of scrub radius, anti-squat, anti-dive. To avoid rollover the vehicles centre of gravity has been put as low as possible, by doing this we have restricted the movement of the centre of gravity to an extent. After establishing the design parameters the team has done different types of market surveys locally and on the internet to find components that are well suited for the purpose, the emphasis was on manufacturing most of the components to avoid outsourcing, although expensive, it would serve all the requirements as well as have clean engineering ethics rather than modifying an existing setup to suit ours. Objective of steering system: ● Allow for sharp steering angles. ● Allow for extended suspension travel. ● Provide straight-line stability. ● Minimize bump steer. ● Have good steering return ability ● Be precise and compact. 3. 2 Types of Suspensions 3. 2.1 Dependent suspension system This type of system normally has an axle which holds both the wheels parallel to each other and perpendicular to the axle. When certain amount of changes occur in one wheel due to some external causes such as bump then the same amount of changes occur in the other wheel in the same manner.

- 11. 11 Dependent systems may be differentiated by the system of linkages used to locate them, both longitudinally and transversely. Often both functions are combined in a set of linkages Types of dependent suspension system are: 1. Solid axle 1. Solid axle over leaf spring 2. Solid axle over coil spring 2. De-Dion 3. Torsion beam suspension 1. SOLID AXLE: A solid axle also known as beam axle is a dependent type of suspension system in which a single beam or a solid axle or a shaft is connected to a pair of wheels in a lateral manner. With a beam axle the camber angle between the wheels is the same no matter where it is in the travel of the suspension 1. Solid over leaf spring: A Leaf Spring is a simple form of spring commonly used in heavy commercial vehicles and four wheeled drive vehicles. The leaf spring is arc-shaped and works by suspending the chassis of the vehicle to avoid contact with wheels. In this type of suspension system the drive axle is clamped to the leaf spring and the shock absorber normally bolted directly to the axle. The end of the leaf springs is attached directly to the chassis, as are the tops of the shock absorbers. A leaf spring takes the form of a slender arc-shaped length of spring steel of rectangular cross-section. The center of the arc provides location for the axle, while tie holes are provided at either end for attaching to the vehicle body. For very heavy vehicles a leaf spring can be made from several leaves stacked on top of each other in several layers, often with progressively shorter leaves. Leaf springs can serve locating and to some extent damping as well as springing functions. While the interleaf friction provides a damping action, it is not well controlled

- 12. 12 and results in restriction in the motion of the suspension. It can either be attached directly to the frame at both ends or attached directly at one end, usually the front, with the other end attached through a shackle (a short swinging arm). The shackle takes up the tendency of the leaf spring to elongate when compressed and thus makes for softer springiness. There are several types of leaf springs available based on number of leafs stacked on each other and the geometry of the spring few of which are mono-leaf spring, elliptical leaf spring, semi-elliptical leaf spring and more. In the modern implementation of parabolic leaf spring. The design is characterized by fewer leaves whose thickness varies from center to ends following a parabolic curve. In this design, inter-leaf friction is unwanted, and therefore there is only contact between the springs at the ends and at the center where the axle is connected. The main advantage of parabolic springs is their greater flexibility, which translates into vehicle ride quality. The basic advantage of this type of setup is that the leaf spring acts as a linkage for holding the axle in position and thus separate linkage are not necessary. It makes the construction of the suspension simple and strong. But as the positioning of the axle is carried out by the leaf springs so it makes it disadvantageous to use soft springs i.e. a spring with low spring constant. This type of suspension does not provide good riding comfort. The inter-leaf friction between the leaf springs affects the riding comfort. Acceleration and braking torque cause wind-up and vibration. Also wind- up causes rear-end squat and nose-diving. The main drawback with this arrangement is the lack of lateral location for the axle, meaning it has a lot of side-to-side slop in it. 2. Solid over coil spring: This is a variation and update on the system described above. The basic idea is the same, but the leaf springs have been removed in favor of either ‘coil-over-oil’ spring or shock combos. A coil spring, also known as a helical spring, is a mechanical device, which is typically used to store energy due to resilience and subsequently release it, to absorb shock, or to maintain a force between contacting surfaces. They are made of an elastic material formed into the shape of a helix which returns to its natural length when unloaded. Because the leaf springs have been removed, the axle now needs to have lateral support from a pair control arms. The front ends of these are attached to the chassis, the rear ends to the axle. The variation shown here is more compact than the coil-over-oil type, and it means we can have smaller or shorter springs. This in turn allows the system to fit in a smaller area under the car. In addition to cylindrical springs, with which the line of force moves along the damper axis, lateral forces compensating side load springs are produced that have a line running diagonally to the spring center line. Use of side load springs leads to increase in driving comfort, driving safety and optimum use of space due to extensive compensation of lateral forces. One of the main advantage of coil spring is that it gives a better road handling and better braking.

- 13. 13 The principal advantage of the beam axle is its simplicity. This simplicity makes it very space-efficient and relatively cheap to manufacture. Beam axles are also ideal for carrying heavy or varying loads because they do not ever exhibit any camber change as the suspension travels. They are nearly universally used in heavy-duty trucks and most light and medium duty pickup trucks, SUV’s, and vans also use a beam axle, at least in the rear. The drawbacks are that it does not allow each wheel to move independently in response to bumps, and the mass of the beam is part of the unsprung weight of the vehicle, which can further reduce ride quality. Also the cornering ability is typically worse than other suspension designs because the wheels have zero camber angle gain during body roll. 2. DE-DION: A de Dion tube is an automobile suspension technology. It is a sophisticated form of non- independent suspension and is a considerable improvement. A de-Dion suspension uses universal joints at both the wheel hubs and differential, and uses a solid tubular beam to hold the opposite wheels in parallel. Unlike an anti-roll bar, a de Dion tube is not directly connected to the chassis nor is it intended to flex. In suspension geometry it is close to the trailing beam suspension seen on many front wheel drive cars, but without the torsional flexibility of that suspension. With this system, the wheels are interconnected by a de Dion Tube, which is essentially a laterally-telescoping part of the suspension designed to allow the wheel track to vary during suspension movement. This is necessary because the wheels are always kept parallel to each other, and thus perpendicular to the road surface regardless of what the car body is doing. This setup means that when the wheels rebound, there is also no camber change which is great for traction, and that's the first advantage of a de Dion Tube. The second advantage is that it contributes to reduced unsprung weight in the vehicle because the transfer case / differential is attached to the chassis of the car rather than the suspension itself. Naturally, the advantages are equaled by disadvantages, and in the case of de Dion systems, the disadvantages would seem to win out. First off, it needs two CV joints per

- 14. 14 axle instead of only one. That adds complexity and weight. Well one of the advantages of not having the differential as part of the suspension is a reduction in weight, so adding more weight back into the system to compensate for the design is a definite disadvantage. Second, the brakes are mounted inboard with the calipers attached to the transfer case, which means to change a brake disc, you need to dismantle the entire suspension system to get the driveshaft out. (Working on the brake calipers is no walk in the park either.) Finally, de Dion units can be used with a leaf-spring or coil-spring arrangement. With coil spring it needs extra lateral location links, such as a Panhard rod, wishbones or trailing links. Again - more weight and complexity. de Dion suspension was mostly used from the mid 60's to the late 70's and could be found on some Rovers. More recently deDion suspension has had somewhat of a renaissance in the specialist sports car and these all uniformly now use outboard brake setups for ease- of-use, and a non-telescoping tube, usually with trailing links and an A-bar for lateral location (rather than a Watts linkage or Panhard rod). Unlike most fully independent suspension there are no camber changes on axle loading and unloading (or rebound). Fixing the camber of both wheels at 0° assists in obtaining good traction from wide tires and also tends to reduce wheel hop under high power operations compared to an independent suspension. And with this setup the designer has free will to opt for various shock absorbers. The most disadvantageous point is the manufacturing cost of this setup which is high when compared to other types of setup. 3. TORSION BEAM SUSPENSION: A torsion bar suspension, also known as a torsion spring suspension or torsion beam suspension, is a general term for any vehicle suspension that uses a torsion bar as its main weight bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end terminates in a lever, the torsion key, and mounted perpendicular to the bar that is attached to a suspension arm, a spindle, or the axle. Vertical motion of the wheel causes the bar to twist around its axis and is resisted by the bar's torsion resistance. The effective spring rate of the bar is determined by its length, cross section, shape, material, and manufacturing process. The ride height may be adjusted by turning the adjuster bolts on the stock torsion key, rotating the stock key too far can bend the adjusting bolt and more importantly place the shock piston outside its standard travel. Over-rotating the torsion bars can also cause the suspension to hit the bump-stop prematurely, causing a harsh ride. Aftermarket forged-metal torsion key kits use relocked adjuster keys to prevent over-rotation, and shock brackets to keep the piston travel in the stock range. One of the main advantages of this setup is that its durable and it allows the user to adjust the ride height with an ease. And the amount of space occupied by this setup s less when

- 15. 15 compared to coil spring suspension. And one of the main disadvantage of this type of setup is that it cannot a progressive spring rate like a coil spring suspension setup. 3. 2.2 Independent Suspension System Unlike dependent system an independent suspension system allows wheels to rise and fall on their own without affecting the opposite wheel There are several types of geometry present in this type of suspension system among which few are: 1. Double wishbone 2. Macpherson strut 3. Semi-Trailing arm 1. DOUBLE WISH BONE: This type of system is also known as A-arm or wishbone type of suspension system. This type of suspension system is a design using two wishbone shaped arms placed parallel to each other in a vertical manner and are locate to the wheel. Each wishbone or arm has two mounting points to one at the chassis and the other at the joint of the knuckle on top and bottom. The shock absorbers are mounted to the wishbones to control vertical movement. Double wishbone designs allows carefully to control the motion of the wheel throughout suspension travel, controlling parameters such as camber, caster angle , degree of toe, roll center height, scrub radius, scuff and more. The upper arm is usually shorter to induce negative camber, and often this arrangement is titled an "SLA" or short long arm suspension. When the vehicle is in a turn, body roll results in positive camber gain on the lightly loaded inside wheel, while the heavily

- 16. 16 loaded outer wheel gains negative camber. Each arm is connected to chassis from one side and to the knuckle on the other. Double wishbone suspension setup allows the engineer to mount shock absorbers at ease. It is easy to work out the effect of moving each joint, which helps in easy tuning of kinematics of the suspension and wheel motion can be optimized. It is also easy to work out the loads that different parts will be subjected to which allows more optimized lightweight parts to be designed. They also provide the engineer for easy tuning of camber gain, unlike the Macpherson strut, which provides negative camber gain only at the beginning and then reverses into positive camber gain at high jounce amounts. As disadvantage, it may take more space and is slightly more complex than other systems like a Macpherson strut. Due to the increased number of components within the suspension set up it takes much longer to service and is heavier than an equivalent Macpherson design. Double wishbones are usually considered to have superior dynamic characteristics as well as load-handling capabilities, and are still found on higher performance vehicles. Examples of makes in which double wishbones can be found include Alfa romeo, Honda and Mercedes-benz., double wishbone suspension, is very common on front suspensions for medium-to-large cars and is very common on sports cars and racing cars. It also provides least camber change at bump and rebound condition. MACPHERSON STRUT: This type of system is currently the most widely used front suspension system in most of the cars. Macpherson struts consist of a wishbone or a substantial compression link stabilized by a secondary link which provides a bottom mounting point for the hub or axle of the wheel. The system basically comprises of a strut-type spring and shock absorber combo, which pivots on a ball joint on the single, lower arm. The strut itself is the load-bearing member in this assembly, with the spring and shock absorber acting as a member holding the car up. The Macpherson strut required the introduction of unibody or monocoque construction, because it needs a substantial vertical space and a strong top mount, which monocoque body can provide, while benefiting them by distributing stresses

- 17. 17 The biggest advantage of this type of setup is the low manufacturing cost and the simplicity of design, it is not generally considered to give as good handling and the quality of ride as double wishbone geometry. Despite these drawbacks, the Macpherson strut setup is still used on high performance cars. SEMI-TRAILING ARM: A semi-trailing arm suspension is an independent rear suspension system for automobiles where each wheel hub is located by a large arm that pivots at two points. This type of suspension employs two trailing arms which are pivoted to the car body at the arm's front edge. The arm is relatively large compare with other suspensions' control arms because it is in single piece and the upper surface supports the shock absorber. It is rigidly fixed to the wheel at the other end. Viewed from the top, the line formed by the two pivots is somewhere between parallel and perpendicular to the car’s longitudinal axis. It is generally parallel to the ground. Trailing-arm and multilink suspension designs are much more commonly used for the rear wheels of a vehicle where they can allow for a flatter floor and more cargo room. Many small, front-wheel drive vehicles feature a Macpherson strut front suspension and trailing-arm rear axle.

- 18. 18 Advantage of this type of setup us that it has anti-lift effects while braking. A disadvantage of this suspension setup is that during roll in a turn, the rear wheels attain a positive camber angle equal to the roll angle of the car body, reducing slightly the rear axle cornering capacity. Another disadvantage is that it complies to toe-out under lateral loads. This tends to promote over-steer. To reduce this tendency, trail arm bushings need to be highly stiff and rigid, which increases ride harshness. 4. Front Suspension for BAJA Vehicle 4. 1 Selection of type of suspension With the premise of introduction of suspension in chapter 2, the design of front suspension for the BAJA vehicle is described in this chapter. After reviewing various types of suspension geometries the “Double ‘A’ arm” setup was preferred as it met many of our criteria which were: ● Adjustability. ● Ability to package in a small space. ● Simpler construction. ● Lightweight yet robust construction. Main components of the suspension system (front): ● Wishbones or “A” arms ● Uprights or Knuckles ● Hubs ● Stub Axles ● Mounting tabs ● Shock absorbers A standard double “A” arm or double wishbone geometry consists of two links that are used to connect the chassis to the upright. The two links namely, upper wishbone and lower wishbone each of which is provided with two revolute joints at the chassis end and one rotational joint at the upright. The design of suspension earlier was done using paper doll-models connected with threads to verify the motion, but in a more sophisticated way the design has been done using various computer software’s that provide better accuracy and analysis.

- 19. 19 4. 2 Suspension Geometry The primary design constraint for designing the front suspension was the track width limitation which was set to 64” by the BAJA SAE official rulebook, after adding some human error and tolerances in installation we have decided on an optimum track width of 60” which would be the maximum achievable track width for us basing on our manufacturing standards without the risk of exceeding the governed track width. Maximum track width was chosen in order to achieve the highest possible wishbone lengths which directly affect the travel or the motion in a vertical path of the suspension, having a large suspension travel was one of the objectives of the design. Elaborated in later chapters the double wishbone design also offers us a higher stiffness and load bearing capacity per weight than any other type of suspension geometry. Geometric planning: The setup started with a set of unknowns and a set of desired values, important unknown parameters for design of components were: ● Length of wishbones ● Height of uprights ● Kingpin Inclination ● Hub offset ● Spindle offset ● Angles of wishbones with axis at desired ride height ● Wheel offset These parameters were required to design the suspension components for stress analysis as well as for dynamic simulation. Desired suspension characteristics were: ● Low scrub radius ● Ride height ● Height of roll center ● Height of mounting point of steering rack w.r.t lower wishbone. A brief description is given with regards to support the above mentioned requirement. ● Low scrub radius: to avoid excessive scrubbing and premature wear of tyres, double wishbone suspensions induce a scrub radius due to its basic design

- 20. 20 from in which its steer axis does not coincide with its centerline axis, unlike Macpherson strut setup which are inherently zero scrub geometries. The aim is to minimize scrub as much as possible. The scrub radius if affected by the Kingpin inclination, hub offset and wheel offset. ● Ride height: a ride height of 250mm was decided to be adequate to clear most of the obstacles to pass underbody without being obstructed, it also is a good tradeoff between roll, as greater ride heights, greatly influence the position of center of gravity with respect to the ground. ● Height of roll center: the roll center position greatly affects the way the vehicle behaves and also the way in which the forces are transmitted to the chassis through the suspension. Technically speaking the roll centre must be as low as possible to the ground as it will facilitate the transfer of weight into body roll instead of it being transferred to the tyres on their contact patch, therefore to maintain a low roll center the vehicle has to run a very high spring rate and a stiff setup, which is not very ideal in the case of an off-roader where the surface of vehicle operation is not smooth. A roll centre that is very close the chassis will cause excessive jacking forces and put a lot of stress on the suspension mounting points, therefore one needs to run a very low spring-rate but the ride is defined by being “Wobbly” with a lot of movement of the vehicle due to body roll. Therefore the best position chosen for the roll center for the vehicle was somewhere in between the road and the chassis biased towards the chassis in the span of ride height. ● Height of mounting point of steering rack : the position is extremely important as later discussed ‘bump steer’ is greatly influenced by this factor. The position is also important to package the steering rack on to the chassis. 4. 3 Simulation Modelling of link geometry is followed by checking for link-clash or component clash scenarios, such as Full droop, Maximum Bump, Side roll

- 21. 21 Fig. Modelled Link geometry of the vehicle showing various desired as well as calculated values. Full Droop scenario, no link clash detected.

- 22. 22 Max.bump scenario, no link clash detected. Side body roll, no link clash detected. From the above analysis it is noted that the design satisfies the requirements and does not have any aberrant effects, the link geometry is also found to be good. Wishbones or “A” arms: they are the control arms that allow for the travel of the suspension in a controlled manner. Between the outboard end of the arms is a knuckle with a spindle and hub. The wishbones are provided with bushing or rod ends, to constrain their motion and allow motion only in desired path. The bushes also provide a noiseless operation of the system. Selection of Shocks: The shock absorbers used in the 2014 BAJA vehicle are air shocks manufactured from FOX racing corporation, California, USA. They have been acquired as part of POWERSPORTS SAE/MINI BAJA program, the shocks provide a lightweight solution

- 23. 23 to the heavy coil-overs add to that the ability to run variable spring rates, ability to tune as per driver specific requirements equal or surpass our requirement. Specification of the shocks: Manufacturer brand and model FOX Racing, Float 2. Weight 0.8Kg Length 18.8” ( Extended ) Width 6.2” Travel 6” Performance characteristics of the shocks: Motion ratio : The ratio of the variables d1 and d2 and the angle between the shock mounting with the vertical as shown in the figure below image courtesy : Eibach motorsport.

- 24. 24 This ratio is based on the leverage theory of levers, mathematically represented by: MR = (d1/d2) ∗ ACF Where, ACF=cosA 9 (angle correction factor) MR = (261/522) ∗ cos45 MR = 0.35 The value of the motion ratio has been kept close to 0.35, which creates a smoother ride, while maintaining the required stiffness. The following table shows the calculated values of frequency and wheel rate.

- 25. 25 Fig. Suspension frequency for various vehicles, reference: Optimum Kinematics. The suspension frequency is 1.57Hz which is moderate and as per allowed limits. Simulation : The calculated values from the earlier designs has been modelled in a 3d vehicle dynamics software “LOTUS Engineering, Suspension Analyzer - SHARK module”, this software allows us to accurately model the suspension system and run tests for scenarios such as 2d bump, 2d steer,3d bump, 3d steer, 3d roll The figure below shows the front suspension model in LOTUS SHARK.

- 26. 26 Fid. 3 dimensional bump, note there is no excessive camber change or toe change. Fig: 3 dimensional steer. Fig: 3 dimensional roll. Graph 1:Camber (deg) vs Roll angle ( deg)

- 27. 27 the vehicle gains 9 degrees of negative camber at full roll Graph above shows the camber change (deg) with respect to steer travel. The following simulations have been done to ensure the suspension behaves in a planned manner to determine the ride and handling, a lot of testing is required on various terrains, tuning the suspension becomes of paramount importance to achieve the best required control and handling of the vehicle.

- 28. 28 5. Design of Front Suspension Components 5. 1 Design of Control arms 5. 1.2 Modeling The following dimensions for the modeling of upper and lower control arms were provided by suspension analyzer. The length of them were based on front nose dimensions, track width and various other performance significant parameters. The model ought to reflect the lengths mentioned above.

- 29. 29 Various shapes for control arms were considered initially. Since the control arm is the link between tire and body of the vehicle, it need to be stiff and strong to support also control the tire motion. There were a lot of variant in design of control arms few are:

- 30. 30 After studying various design, the finalized design was make it out of a single tube by bending into a parabola.

- 31. 31 Reasons for selection of the design 1. Easy to fabricate 2. Consumes less time in production 3. Sophisticated jig not required 4. Less number of welds hence low heat effected areas. 5. Easy correction in design by opening and closing of bend. The upper wishbone according to geometry was prepared as following

- 32. 32 The upper stock connected the upright. It will be inserted by stock steering rod ends of a commercial vehicle. The model of lower wishbone is different from the mentioned as it needs to mount the shock absorber. It is done by providing a lateral tube with the mount. Since the design is for front suspension lower one mounts the shock absorber where as in case of it being used in rear suspension mounts are given on upper wishbone due to obvious reasons

- 33. 33 The tubing for control arm was chosen to be AISI 4130 steel with outer diameter 25mm and 3.5 mm wall thickness. The tabs for shock mount were from 4mm thick mild steel sheet. 5. 1.3 Analysis 5. 2 Design of Upright 5. 2.1 Design parameters Before designing of any components there are various parameter that are to be included in it. Irrespective of other details the main design parameters determine mostly the performance, adaptability with the environment, mates with the sub-component in an assembly, space occupancy etc. They are Special consideration and often are the constrains which are to be met. The parameters that molded the design of the upright were: 1. Include castor angle of 6o along the vertical axes of upright. 2. Project the brake caliper mounts at one side of upright. 3. Provide sufficient thickness to brake caliper mounts to endure sudden torque from the disk rotors. 4. Check alignment of the brake caliper mount on both of the uprights i.e. Left and Right uprights. Since the brake caliper doesn’t have plane of symmetry along its center, brake mounts will have different spacial arrangements along the side of both uprights. 5. Steering arm mount be on the opposite side that of the brake caliper mount of the respective uprights. 6. Twin steering arm mount be provided to facilitate double shear for steering arm bolts. 7. Dual bolt holes will be provided to counteract the moment in the steering arm. 8. Have sufficient fillet radius throughout the design to minimize notch sensitivity. 9. Length of upright will be taken as per the suspension design that gave the optimum results. 10. Upper and lower wishbone mounting will be dependent on the kingpin inclination obtained from the suspension geometry

- 34. 34 11. Bore be provided to accommodate the stub axle. 12. Press fitting tolerance to be provided in the central bore diameter to press fit the stub axle. 13. Sufficient wall thickness to make the component rigid, unsusceptible to external moment. 14. Design optimization will be done after the component is analyzed for various loading cases to relief weight. 5. 2 .2 Material Selection As it was mentioned above in design parameters, weight consideration was the main objective that dictated the choice of material for the suspension components. Also as mentioned earlier the preference of low unsprung mass in the vehicular system, it was necessary to opt the material which could bear the forces induced during the motion as well be light. Market survey revealed the local availability of the following suitable material candidate for the component. 1. Cast Ductile Iron 2. Titanium Alloy Ti 6Al-4V 3. Aluminum Alloy AA 6351 T-6 4. Alloy Steel AISI 4140 Specific Strength comparison It is the strength to weight ratio of the material. Strength here can be tensile or yield strength. A higher ratio dictates the material has appreciable strength compared to its weight.

- 35. 35 The above graphs shows the usage of Titanium alloy to be most apt choice for the component. Nevertheless other factors also have be considered before material selection is to be made. Cost per unit yield strength Comparison also has to be made with the cost of the material. The cost comparison (C) is made by following equation; 𝐶 = 𝑐 𝑚 ∗ 𝜌 𝜎 Whereas, Cm ꞊ Cost of the material per unit mass (Rs/Kg) 𝜌 ꞊ Density of the material (Kg / m3) σ ꞊ Yield strength of the material (N/m2 ) 77674.6 186816.4 101851 58598.7 0 20000 40000 60000 80000 100000 120000 140000 160000 180000 200000 Ductile Iron Ti6Al4V AA 6351 T6 AISI 4140 SPECIFICSTRENGHTNM/KG

- 36. 36 Ductility Defined as the percentage elongation under stress before the material ruptures. This property is important as it gives a clear warning before the metal breaks down. The above graph shows the cost value for unit strength of the material. It can be seen that Titanium alloy have the highest value for its strength whereas ductile alloy have the least. Interpretations from above three detrimental property graphs; 1. Titanium and aluminum seems to be viable candidates where the strength to weigh ratios are to be considered. 0 2000 4000 6000 8000 10000 12000 14000 16000 18000 Ductile Iron Ti6Al4V AA 6351 T6 AISI 4140 SPECIFICCOSTRSKG/MN 0 5 10 15 20 25 30 Ductile Iron Ti6Al4V AA 6351 T6 AISI 4140 ELONGATION%

- 37. 37 2. Ductile cast iron is the cheapest material which is to be considered, also fact that most of the commercial automobile are fit with ductile cast iron uprights. 3. Titanium alloys have the highest specific cost among all Considering all the above, it has been decided AA 6351 T-6 seems to be the most viable material for the component. The strength on weight ratio is sufficient to meet our standards. Choosing aluminum alloy also seems to be a most economical selection. Since Aluminum alloy have been chosen, fatigue characteristics of haven to be taken into account. Components subjected to fluctuating loading fail at much lower loads than their service loads due to fatigue. When not considered in the design stage it can lead to catastrophic failures in their service life. Factors causing a fatigue loading may be many which are: 1. Large fluctuation of Loads i.e. Stress amplitude of high magnitude 2. Sufficient large number of cycles of stress applied Additional factors which may exaggerate fatigue failure are: 1. Corrosion 2. Residual stress 3. Stress concentration 4. Temperature 5. Surface finish 6. Stress range 7. Use of welding The mechanism of fatigue failure can be simple put into two stages i.e. crack initiation and crack propagation to the point of static failure. This crack once formed begins to grow in each cycle of loading. Growth is also accelerated by higher amplitude of loading often characterized by multiple cracks initiated. Final catastrophic failure occur when a crack has grown to a significant length such that the next application of load results in static failure due to reduced area in that region. Fatigue cracks may start at various places such as at concentration of plastic strains, extrusion or intrusions of the surface, grain boundaries, internal voids and surface scratches. Design methodology for any aluminum component used in car was to: 1) Load be highly approximated to actual condition which is being acted upon the component

- 38. 38 2) Optimize the component so that the life of the component be under 105 cycles 3) Check for maximum stress under the stated endurance range instead of checking for yield criteria. 5. 2.3 Modeling The uprights geometry determines the dynamic characteristics of the vehicle. Irrespective of the model, geometry is kept same in all the models. The models prepared were first based on manufacture feasibility, economic consideration and analytical sustainability. Various models were initially prepared for the same. The following are the various models prepared and the reasons for disapproval of the designs.

- 39. 39 Design-1 : Saruman The first of the designs was initially desired to be made up of Steel plates. The plates were given the thickness of 10mm. The plates were countered cut with the required measurements and profile. Joining process was chiefly welding i.e. TIG (Tungsten Inert Gas) welding. Adaptability of the Design : o Cheap material cost o Easy Manufacturing o Less event completion time o Provision of steering stopper Disapproval of Design o Weight of the component- 2.5 Kgs. Since high thickness of plates were being used the weight of the component was considerably

- 40. 40 high. Also use of 10mm thick sheet was indispensable as any reduction of thickness was detrimental. o Low fatigue strength Since the plate were joined by welding process the fatigue strength of the component was considerably effected. This is because uncontrolled cooling and heating rates produced around the weld zone, also called as heat effected zones. This microstructural variation produces areas of high hardness whereby reducing strength. o Steering upright geometry not accurate Since manual fabrication processes were being employed, the dimensional accuracies were uncertain. Design-2 : Gollum Mild Steel pipe of outer diameter 65mm and thickness of 2.5 mm was found to be adequate to press fit wheel bearing. The profiled Mild steel rods following the geometry was welded to the mother rim. Adaptability of design

- 41. 41 o Simple design o Easy manufacturing o Easy procurement of the materials required Disapproval of design o Intricate couping requirement. o Welding reduces the fatigue strength and improper hardness in the sample. o Strength not uniform due to alternate heating and cooling rates. o Brake mounting arms are weak. Brake mounting arms due to relative length from the parent pipe, became long and prone to failure o Weight of the component As mild steel tubes were used the weight of the component was measured up to 1.2 Kgs. o Poor Strength Finite Element analysis found it to be weak at weld zones. Hence prone to failure

- 42. 42 Design-3 : Gandalf Stock Aluminum alloy 6351 T-6 would have been used. Manufacturing process being CNC milling. Adaptability of design o Geometry of the upright was captured better o CNC milling process was fast and accurate o High torsional rigidity. Disapproval of design o Mounting points for upper and lower wishbone was too small whereby increasing stress in those areas. o Increasing the upper and lower wishbone mount areas increased the weight of the component considerably.

- 43. 43 o Weight of the component It weighs 2.5 Kgs comparable to its steel counterpart. Design-4 : Bilbo It was then decided to provide stub-axle on the upright itself. The aluminum Upright was then modeled to be CNC milled. Adaptability of design o Fast and accurate manufacturing o Holes and slots provided to relief weight. It weighs only 760 gm. The least weight until now. o Geometry captured accurately and effectively o Bearing size is considerably reduced, whereby reducing weight.

- 44. 44 o Bearing lock could be provided on built in stub axle Disapproval of design o Many relief holes increased notch sensitivity of the component o Built in stub axle cannot have wheel bolt as threading on aluminum shears off easily. o Required hub offset cannot be changed. o In case of failure of stub axle whole upright have to be changed o Longer stub axle created immense bending strength on upright o Fillets and notches are requirement on the stub axle to be able to hold other components well. These fillets and notch sensitivity added up stress on bending stress, creating more stress it can hold o Built in stub axle was failing in large loading conditions. o Longer steering arm also made it more susceptible to shear from the upright o Also built in steering arm dictates changing the upright when steering arm fails, the failure which is very common in the testing. Rejection of all the other designs was valid as even though they all met with the requirement of designing parameters but failed at various other important suppositions. New design was required to have the modeling advantages of all other designs at the same time to rectify all the drawbacks of the previous designs. The new and improved design was modeled in the following steps. Step 1: The basic mold was created around the upright geometry. This captures almost all the features which were important to suspension design.

- 45. 45 Step 2 : The next step was to differential the upper and lower wishbone mounting positions. An arbitrary thickness was given which will be verified once the model is added to testing module. Care was also taken care to be able to provide sufficient room for accommodation of castle nuts. Step 3 : The brake mount position was carefully positioned so as when brake caliper in engagement would reach the end of the brake disk, for it to hold it firmly when under braking effect. The longer brake mount was given a parabolic profile to have a uniform strength also to reduce material. After calculated width of material was left for the center hole on the upright which would hold the stub axle. The extended length of the steering arm was reduced to decrease the added moment at the end of the upright. Step 4: After bail calculation considering the material, diameter and step dimensions for the stub axle. the central bore for the same was provided on upright

- 46. 46 Step 5: It was seen as an added strength to steering arm by placing its bolt under double shear. Also to counteract the effect of couple number of holes for its bolts were increased from 1 to 2. Step 6: The castor was given 5 degrees, according to which the position of upper and lower mounting points were determined. The hole diameter was kept equal to the rod-end diameter.

- 47. 47 The model was thus prepared with rectifying all the drawbacks obtained from the previous failures of various models, also every model was an improvement over the other until the final design (Hobbit) was considered to be selected. The various dimension were kept variable in view of further analysis. Finite element analysis will dictates all the dimension of the component. 5. 2.4 Loading scenarios Contemplation of actual force distribution on a single suspension component during motion of car can be quite complicated. To ease this complication and various

- 48. 48 complicated vector forces experienced by the component, it is usually split down into various individual scenarios. These scenarios take up the maximum force derived from calculation and constrains the model appropriately to represent the actual event. The following scenarios of loading will be considered for the analysis 1. Steering effort 2. Brake mounting force 3. Remote loading 4. Cornering Force It is to be noted that weight of the component was considered during analysis. 1. Steering Effort Calculation, As steering effort was calculated in section-12, Steering effort (Fst) is taken as 1.5g 𝐹𝑠𝑡 = 4400 The tie rod being designed to take purely axial load, whereas such is not the case with steering arm. As the wheel travels the direction of forces changes. To accommodate this effect the direction of steering force wasn’t taken parallel to ground but at an angle 45o with the horizontal. Then components along X and Y comes out to be equal i.e. 𝐹𝑠𝑡 𝑥 = 𝐹𝑠𝑡 𝑦 = 3100 2. Braking Mount force calculation,

- 49. 49 The following free body diagram shows the position of brake caliper mounting pints with respect to center of the disk. This is because the brake mounting position is not symmetrical with the center of the caliper. And hence the force experienced by the each mount will be different. Braking Mount Force (Fbm) 𝐹𝑏𝑚 = 𝑇𝑏 𝑟𝑏 By sum of forces and applying moment at a point we get, Force on larger brake mount ꞊ 3200 N Force on smaller brake mount ꞊ 2300 N 3. Remote loading Due to rim and hub offset, the bumps force is not a direct loading but an eccentric loading. The values of the mentioned dimension have already been calculated. Fshock have already been calculated (6. c.vi) ꞊ 22,000 N 4. Cornering force As per calculation the cornering force was taken to be 1.5g 𝐹𝑐𝑜𝑟𝑛𝑒𝑟 = 5000

- 50. 50 5. 2.5 Analysis An upright is the crucial component as every force experienced by the car is passed on through it. Also analyzing every effect of this complex ever changing moment and forces becomes complicated. A worst case scenario’s is therefore recommended where forces are scaled and restrains are applied in view of real time. The team performed various finite element computational analysis to match approximately with the actual conditions that will be experienced by the component so as to avoid failure in real-time. There are many different types of analysis that must be completed to ensure that the part in question is able to withstand the applied loads. In addition, there are other factors that must be included in each analysis to ensure that the analysis itself is correct. In order to analyze the part correctly, the restraints must be an accurate representation of the real world scenario and the loads must be calculated for different loading scenarios. Finally, the mesh must be as homogenous as possible. This would include minimizing the difference in aspect ratio between elements, as well as maximize element mapping quality. We must ensure that all of the meshes we use for the different components in our assembly are set up to be compatible with one another. The main objective behind analysis was to check the maximum stress induced, predict the life of component and establish a suitable factor of safety in design. Since most of suspension component used were aluminum it must be noted forth that it doesn’t exhibit a fixed fatigue limit unlike major steel categories. All of the analysis was done in student package of Solid works 2013 Simulation module. The meshing package utilizes the tetrahedral mesh on the component. To give better accuracy the mesh size was made finer until the results became stagnant. Any more decrease in mesh size would just waste computer resource without marginally increasing any solution accuracy.

- 51. 51 Modal analysis was also done on the component to determine how the system behaves in its displacement dynamic response. It was done to check how different frequencies naturally excite the system to a degree where resonance fluctuates through the component resulting in dropping of life expectancy of the system. For this study no external load is applied to the component, while it is known that external loads do not affect the natural frequency. The component was however restrained. In all the analysis self-weight of the component was considered. Scenario Bump loading Loading Stub-axle bore at an offset of 50mm Constrains Upper and lower wishbone mounting Force 22,000 N Maximum Stress 109 MPa Maximum Deflection 0.053 mm Factor of safety 2.42 Scenario Brake caliper mount loading Loading Caliper holes Constrains Upper and lower wishbone mounting Force 3200, 2300 N respectively Maximum Stress 100 MPa Maximum Deflection 0.3 mm

- 52. 52 Factor of safety 1.88 Scenario Cornering of vehicle Loading Upper and lower wishbone mounting Constrains Stub-axle bore Force 5000 N Maximum Stress 53 MPa Maximum Deflection 0.16 mm Factor of safety 4.91 Scenario Steering of vehicle Loading Steering arm holes Constrains Upper and lower wishbone mounting points Force 3000 N Maximum Stress 90 MPa Maximum Deflection 0.13 mm Factor of safety 2.73 The above plots of the results for various cases that might be experienced the component during its operation life cycle

- 53. 53 Being the suspension component of an automobile, it is under constant non uniform loading condition. Also the loading condition vary drastically from terrain. In order to simplify the loading scenarios fully reversed loading i.e. R (Stress Ratio) ꞊ -1 was preferred over other stress ratios ranging from -∞ to ∞. The tabular values of Sa (Stress amplitude) with the corresponding life cycles [1] was fed into Solid works Fatigue Analyzer. The corresponding S-N diagram was obtained from the data. Solid works doesn’t have built in S-N graphs for all the materials that are present in its directory, hence it was needed to plug them manually into the software. Following is the obtained fatigue data that has to be fed into the system to perform fatigue analysis. Table 1: Fatigue data distribution for Aluminum 6061 T6 No of Cycles Stress Amplitude (Zero Mean Stress) N/m2 10.000000 482000000.000000 70.000000 482000000.000000 100.000000 420000000.000000 200.000000 325000000.000000 500.000000 241000000.000000 1000.000000 198000000.000000 2000.000000 168000000.000000 5000.000000 142000000.000000 7000.000000 135000000.000000 10000.000000 120000000.000000

- 54. 54 20000.000000 99000000.000000 50000.000000 80000000.000000 100000.000000 71000000.000000 200000.000000 64000000.000000 500000.000000 58000000.000000 1000000.000000 55000000.000000 2000000.000000 53000000.000000 5000000.000000 51000000.000000 10000000.000000 50000000.000000 20000000.000000 49880000.000000 50000000.000000 49280000.000000 100000000.000000 48990000.000000 200000000.000000 48700000.000000 500000000.000000 48500000.000000 1000000000.000000 48400000.000000

- 55. 55 Figure 1: S-N curve for zero mean stress of Aluminum 6061 T6 The fatigue analysis could be done for individual scenarios however for a combined force situation it seems logical to optimize. For this bump force, heavy braking, steering pull were applied to component.

- 56. 56 It can be seen the life of the component is well defined for more than 95% area having 1E9 cycles. Some of the areas shows a reduced life but that can be ignored potentially. All attempts were made to restrict the maximum von misses stress under 100 MPa, after studying the fatigue properties of aluminum. Also not compromising on weight gave the best combination of strength, weight and fatigue characteristics for the component. 5. 3 Design of Front Hub 5. 3.1 Introduction A wheel hub is a mounting position for wheel of the vehicle, it houses the wheel bearing as well as supports the lugs and brake disk. It can either transmit power or be just rolling. Its function is basically to keep the wheel spinning freely on the bearing while keeping it attached to the vehicle. Designing a hub is very crucial as it alones is the interface between the wheels and rest of the vehicle. Lug bolts are usually integral to hub, hence these are also called as locking bolts. Spacers are also used to fit between the hub and the brake disks. This is done to accommodate different brake calipers as to avoid the scraping between them and the calipers. Usually in hubs in commercial vehicle are made up of alloy steels or cast iron. But for a mini Baja vehicle it is advantageous to look at alternative material to make it light weight.

- 57. 57 5. 3.2 Bearing selection Selection of suitable bearing for a particular purpose is immensely important in view of the load it is meant to take at given rotational speed giving a certain life. Max gear ratio of the transmission, 7.6 Max rpm of the engine crank, 3800 𝑟𝑝𝑚 The maximum rotational speed attained by the tire is, 500 𝑟𝑝𝑚 Assuming the life of the bearing to be designed for is, 1000 ℎ𝑜𝑢𝑟𝑠 Loading ratio (From data book) 𝐶 𝑃 = 3.11 Axial Force is assumed to be during cornering, which is taken as 1.5g (Pr) 2500 𝑁

- 58. 58 Radial Force is the drop weight of the car (Pa) 4000 𝑁 the ratio of axial to radial, 𝑃𝑎 𝑃𝑟 = 0.45 for the corresponding ratio, the value of equivalent load 𝑃 = 𝑆(𝑋𝑃𝑟 + 𝑌𝑃𝑎) 𝑃 = 4000 𝑁 The dynamic load carrying capacity was found out to be, 12995 𝑁 For the given life and load rating the bearing number SKR 6007 was chosen for the front wheels. The given are dimensions of the bearing 5. 3.3 Designing Parameters & Considerations Following are the Parameters which guided the design of Front Hubs,

- 59. 59 1. Pitch Circle Diameter of Lug Bolts on rim Since stock Maruti rims were chosen to be on the vehicle on all four wheels. In order that the hub to sit on rim, the pitch circle diameter of the rim had to match with the designed hubs. Pitch Circle Diameter of Lug bolts on hub ꞊ 144 mm 2. No of Lug bolts and their size Since the rim had 4 equi-spaced lug bolts holes. With the hole size of 12.5 mm diameter. The holes to match with rim had to be provided on hub. 4 Lug Bolt holes with diameter ꞊ 12 mm ø 3. Bearing Provision Since as mentioned earlier the bearing selected was SKF 6007. The bore on the hub with sufficient tolerance is to be provided for the bearing to sit inside the hub. The bearing bore on hub ꞊ 62 −0.03 0 4. Bearing Seat For able to lock the bearing in the hub on one end it should have bearing seat. The thickness of seat must be enough to withstand axial force while cornering. 5. Common Holes for Rim and Brake disk mounting Common holes for both rim and brake will minimize the number of holes from 8 to 4 on the hub. 6. Bearing Lock provision On other end of the hub, the bearing will be locked by an internal circlip. A groove of 2mm is to be provided to facilitate the circlip. 5. 3.4 Modeling A literature survey was undertaken before modelling of the component began. Initially as a reference the stock Maruti hub was taken. The model was loaded in the Solid-works. Initially it was decided to use it but due to its weight idea was soon dropped. Also component was analyzed to develop a lighter and stronger equivalent in aluminum alloy.

- 60. 60 The details in the model were removed to simplify the analysis. The brake mounting holes were also removed to see the effect of analysis. Since the goal of the analysis will be to target potent areas of weight reduction and geometry changes to suit the Baja vehicle. Such method reduces the chances of failure of design as the adopted design is commercially utilized. Also as mentioned in design parameter stub axle will be eliminated in the front hubs to accommodate hub bearing which in turn will hold the axle. An arbitrary force of any value have been loaded on the stub axle of the hub in context. The constrains were the lug holes. The plot shows the stress distribution close to stub axle extending towards lug holes. It was also evident that rest of the area experienced a relatively less induced stress. A plot of design insight reveals the observation to a scaled level.

- 61. 61 The study of stock hub gave us the insights to new design of the hubs that would be precisely follow its design guidelines. Following is the timeline of the model of the component. The blank is initially made and stepped to host the wheel bearing. Provision is also given to lock the bearing in the other direction by a bearing seat. The Pitch circle diameter equivalent to rim is kept on the hub.

- 62. 62 A single chuck of material is removed to observe the effect. The pattern is then repeat around to obtain optimized wheel hub. The grove for the circlip is provided to lock the bearing in opposite direction. Hence modelling is complete. 5. 3.5 Loading scenarios Following are the various loading that were applied to hubs for analysis. This of these forces so obtained will help the prediction of actual results. 1. Drop test

- 63. 63 This test try to replicate stress produced when the vehicle falls from a certain height. To obtain the impact load on the hubs, Assuming the vehicle falls from the height (h), ℎ = 1 𝑚 The impact velocity (v) of the vehicle is, From kinematic relation for rectilinear motion 𝑣 = √(2 ∗ 𝑔 ∗ ℎ) − 𝑢2 whereas, g ꞊ acceleration due to gravity (9.8 m/s2 ) u ꞊ Initial velocity of the vehicle before the fall ( 0 m/s) Substituting the above value, 𝑣 = 4.42 𝑚/𝑠 And now for calculating the impact force (F) From Work-Energy Principle, Change in Kinetic Energy of the object ꞊ Work done on the object 1 2 𝑚 ( 𝑣2 − 𝑢2) = 𝐹 ∗ 𝑑 whereas, d ꞊ the compression of the shock springs ( 0.15 m) Thus, 𝐹𝑠ℎ𝑜𝑐𝑘 ꞊ 22,800 𝑁 2. Braking Torque Test This test analysis the effect of panic braking on wheel hub. Since brake disk and hub are directly connected, while under braking, brake disks induces opposite torque on the hub to halt the vehicle. Assuming the vehicle comes to a complete halt from 55 Km/h in a distance within 6m on an off-road track. Initial velocity (u) ꞊ 15.2 m/s

- 64. 64 Braking distance (d) ꞊ 6m Deceleration (ad), 𝑣2 = 𝑢2 + 2 ∗ 𝑎 𝑑 ∗ 𝑑 whereas, v ꞊ final velocity thus, 𝑎 𝑑꞊ 11.7 𝑚/𝑠2 Assuming weight distribution is 50:50, Force on Front wheels (Ff), 𝐹𝑓 ꞊ 2047.5 𝑁 Braking torque on front wheels (Tf) is, 𝑇𝑓 ꞊ 𝐹𝑓 ∗ 𝑅𝑡 whereas, Rt ꞊ Radius of Tire (0.3048 m) Thus, 𝑇𝑓 ꞊ 624 𝑁𝑚 3. Cornering & Skidding Slip angle changes at the turn of the vehicle, sometimes amateur driver may fail understand its significance and it results in vehicle skidding in turns. It has been taken as 1.5g force for skidding whereas 1g for cornering force. As speed of the vehicle is restricted the assumed values holds good. Cornering Force ꞊ 3500 N Skidding Force ꞊ 5200 N 4. Rim fracture In the event of a rim failure, i.e shear of rim across the lug bolts or failure from flange, it produces an eccentric loading at the hub due to its rim offset. To take this into account the self-weight of the vehicle will be taken in consideration.

- 65. 65 5. 3.6 Analysis Scenario Drop Test Loading Central bore Constrains 4 Lug holes Force 11,000 N Maximum Stress 100 MPa Maximum Deflection 0.041 mm Factor of safety 2.5 Scenario Braking Test Loading Central bore Constrains 4 lug holes Torque 700 Nm Maximum Stress 83 MPa Maximum Deflection 0.022 mm Factor of safety Scenario Cornering & skidding Loading Skidding-Bearing seat

- 66. 66 Cornering-Central bore Constrains 4 Lug holes Force Skidding-5200 N Cornering-3500 N Maximum Stress 131 MPa Maximum Deflection 0.049 Factor of safety 1.96 Scenario Rim fracture Loading 3 spokes Constrains Central bore Force 4000 N Maximum Stress 77 MPa Maximum Deflection 0.11 mm Factor of safety 3.2

- 67. 67 To optimize the component even further it was then added into Solid works Optimization. The variable that was kept in the study was the thickness of the blank of the hub. Following results were found, Component name Units Current Initial Optimal Scenario1 Scenario2 thickness mm 8 8 4 4 8 Stress1 N/mm^2 (MPa) 85.493 85.493 172.74 172.74 85.493 Mass1 Kg 0.151107 0.151107 0.115572 0.115572 0.151107 It can be seen that reducing the thickness from 8 mm to 4 mm would increase the max stress in the component to 172.74 MPa which is fairly under the limit. The weight of the component could also be reduced by 25%. But the optimization wasn’t carried out in the fabrication due to reduced fatigue effects. Compo nent name Units Curren t Initial Scenari o1 Scenari o2 Scenari o3 Scenari o5 Scenari o6 bearing seat thickne ss mm 4.5 4.5 2.25 4.5 2.25 2.25 4.5 seat thick mm 5 5 2.5 2.5 5 7.5 7.5

- 68. 68 Compo nent name Units Curren t Initial Scenari o1 Scenari o2 Scenari o3 Scenari o5 Scenari o6 Stress N/mm^ 2 (MPa) 131.28 131.28 150.3 128.02 155.78 160.57 135.51 Mass kg 0.15110 7 0.15110 7 0.11901 1 0.13734 5 0.12954 1 0.14007 0.16487 The optimization was however carried to determine the optimum thickness of bearing seat and thickness center bearing tube. Based on above optimization it was seen to reduce the weight by 10%, the thickness of the bearing seat thickness as reduced to 2.5 mm from 5mm. And hence after optimization the results were sent for fatigue optimizations. To check the life of the component, a combined study was prepared to sum up all the forces in different scenarios. This being done gives us the combined fatigue analysis also saves the time for each individual iterations. Optimizes component Weight ꞊ 132 grams Seat thickness reduced by ꞊ 50%

- 69. 69 Since it was assumed the vehicle to be running 1000 hours at constant speed of 60km/h. The predicted cycles each component has to run is calculated to be 2.8 E8 cycles. The above fatigue plot shows various portion of the component actually close to required value of cycle it was prescribed for. Hence the fatigue analysis were in good agreement with the fatigue design parameters. 5. 4 Design of Front Stub Axle 5. 4.1 Designing Parameters & Considerations Since the primary objective of stub axle was to host hub and upright, it needed to be extremely rigid to sustain heavy loading. Since it is a dead axle in case of front suspension, it experience the bending moment to a large extend. Following are the design parameters that are to be met in modelling for the component to be effective in function, 1. It need to have steps to ensure the bearing locks on one side. 2. Threaded tail to accommodate wheel nut. 3. One sided flange to fit into upright’s one end, hence locking its relative translator motion in a direction. 4. Respective step should shoulder the selected hub bearing. 5. Provide hole for cotter pin on the threaded end. Consideration

- 70. 70 As other components of the system have been modeled, stub axle design is considerably just adjusting the length between upright and hub. Hub offset is again dictated by the suspension geometry. Also it must be noted that in suspension software’s position and space constrain of brake disk is notably ignored. The whole assembly must have to be verified for dynamic interference before the final hub offset can be decided upon. As such the hub offset was changed to 80mm from previously 50mm to accommodate braking component and avoid their interference with rest of the suspension components. The nut for locking of bearing have to selected in such a way that it hold the inner stationary ring of the same. If the dimension aren’t met then use of appropriate washers have be put in place to satisfy the condition. The position of hole for cotter pin have to be in such that the nut is properly locking the bearing. Affirmation only has to be made when the components are physically assembled. 5. 4.2 Modeling Since the modeling dimension were pre-defined by the upright, hub bearing and hub offset. Also in considerations with the detail design parameters the modelled was prepared initially to satisfy all those. When compared with other components of the suspension the stressed volume of the component was just 39 %. Stating that the low stressed region to be carrying 60% of weight. This high mass has to be compromised. Any steps taken to reduce the weight have to be followed by Finite elements analysis.

- 71. 71 Potent steps to reduce the mass of the component would be to bore the component. Also threaded portion can be reduced on diameter. 5. 4.3 Analysis & Material Selection The model was then loaded to FEM solver COSMOL in solid works simulations. Since the selection of material is indeterminate to stresses induced in the component, an arbitrary material value was specified to observe the stress levels. To enact the actual conditions the following constrains were in place. Constrains Contact point of upright Loading Force-1 Longitudinal 5200 N Tire skid force Force-2 Lateral 11000 N Impact force Efficient meshing of the component is very critical to obtain accurate results. Initially by using default meshing conditions it was found that most of the elements aspect ratio were more than 1. Effect of more than 1 aspect ratio includes the stiffness matrix to be unstable whereby reducing effectiveness of the mesh.

- 72. 72 As obtained above the aspect ratio for most of the elements have been close to 1. This is done by reducing the global size of the element. Also areas of low thickness were given mesh control to reduce further the element size by using curvature based mesh. Analysis was run and the maximum stress obtained was 310 MPa. Appropriate material was then selected. It was decided to select AISI 4340 was selected with yield strength 700 MPa. Design optimization had to be done to reduce the obtained mass of the component which when came out to be 700gms. A central bore was made initially of 12mm throughout the component. It was put under Design study to obtain at optimum diameter thereby limiting stress and decreasing the weight of the component.

- 73. 73 After several iterations the software’s shows the serious of results. Design Study Setup Design Variables Name Type Values Units Diameter of bore Range with Step Min:12 Max:20 Step:1 mm Constraints Sensor name Condition Bounds Units Stress1 is less than Max:600 N/mm^2 (MPa)

- 74. 74 Goals Name Goal Properties Weight ( grams) Mass of component Minimize Mass 700 11 of 11 scenarios ran successfully. Compon ent name Units Current Initial Optimal Scenario 1 Scenario 6 Scenario 2 Diameter of bore mm 12 12 20 12 17 13 Stress N/mm ^2 (MPa) 311.2 8 311.2 8 310.5 6 311.2 8 300.5 337.7 1 Mass 603.6 6 603.6 6 425.1 37 603.6 6 502.5 44 586.2 26 Scenari o3 Scenari o4 Scenari o8 Scenari o9 Scenari o8 Scenari o9 Scenari o5 14 15 19 20 19 20 16 296.1 303.2 5 330 310.5 6 330 310.5 6 303.9 2 567.3 98 547.1 74 452.3 34 425.1 37 452.3 34 425.1 37 525.5 56 Hence the weight of the component was decreased by 40 % for the same strength. And hence the

- 75. 75 component was prepared. The above process is different from other design processes as due to many design constrains and parameters, most of the design was already judges, leaving very less flexibility to designer, hence this approach of design was selected to arrive at final model. 6. Rear Suspension for BAJA Vehicle 6. 2 Suspension geometry The rear suspension of the BAJA vehicle is different from the front suspension in the following ways: ● Must be designed to bear greater loads due to rear placement of engine ● Must not allow great camber changes

- 76. 76 ● Allow the live-axle to be fixed without link-clash ● Must not allow toe changes ● Must not allow axle-plunge out. ● Must be independent. With the above premise, the types of suspensions were reviewed again, following which the decision came down to the selection between double wishbone suspension and a trailing arm design. The double wishbone suspension although very adjustable and lightweight would not be a match here as the rear track width limited to 58” which meant that the packaging space will not be enough, the absence of chassis support members to mount the arms led us to the design of trailing arm. Trailing arm suspension provides all the required camber and toe control. Components used in the rear suspension: ● Trailing arm ● Trailing arm mount ● Rear Upright ● Rear hub 6. 3 Simulation The shock absorber calculations are done in a way that is similar to the front suspension, they only differ in way of running higher spring rates to accommodate in order to maintain the sprung mass.

- 77. 77 Fig: Modeled rear suspension also shown are drive shafts. The rear suspension has been spooled to a zero droop rear design, to maintain traction of the rear wheels at all times as they are the wheels that provide power to the vehicle. The rear suspension also has limited travel in order to prevent axle plunge out, the travel is restricted to 6” which was determined after intensive testing. Fig.3 dimensional bump. Fig. 3 dimensional body roll.

- 78. 78 Fig. Camber change in bump and rebound. Fig. Spring travel in bump and rebound.

- 79. 79 Fig. Full car model in LOTUS SHARK. Fig. 3d bump analysis of the full car model.

- 80. 80 Fig. 3d steer analysis of full car model. Studying the positions of the front and rear roll centers, shows the vehicle will be stable as there is no excessive displacement of the said roll center. Therefore after the simulation process, the design of the combination suspension of front and rear is deemed fit for being used in the BAJA vehicle, the body roll and steer characteristics have shown that the suspension will be capable of doing the required job even on the inhospitable terrain. Provided with the zero droop rear design, the vehicle will not encounter any mechanical problems such as axle plunge-out in case of high speed cornering or large potholes. 7. Design of Rear Suspension Components 7. 1 Design of Trailing arm & Rear Upright 7. 1.1 Designing Parameters & Modeling The trailing arm which chiefly locates the rear wheels is important in design point of view as any changes reflect the power transmission ability and many other suspension characteristics. Therefore its design requires careful trial and error. As in our case it’s not just a tube but others connected to it. Some of the consideration that are to be bore before modeling phase begins are:

- 81. 81 1. Length of trailing arm It be such that it projects the c.v shafts in perpendicular to travel of the vehicle. As any deviation from it cause power loss 2. Should accommodate the brake caliper 3. Should have provision in end of it to pass through c.v joint. Also it should be such that even at any articulation it shouldn’t be interference to trailing arm. 4. At appropriate motion ratio, it should have capacity to hold the air shock firmly also allowing relative rotation 5. Should not deflect either ways when cornering. Ideally should not allow any chamber change 6. Should not deform in heavy loading. The diameter and tube be considerably adjusted to loading. 7. A single link should be able to locate the wheels without need of any other links like camber control link etc.

- 82. 82 7. 1.2 Modelling & Analysis With all the consideration in mind the following trailing arm design was modelled. Cup of the trailing arm was created keeping in mind the clearance for cv joint Cut away for articulation of cv shaft Arm was then made to suit the length.

- 83. 83 Holes for upright and plate for brakes was then made accordingly. Shock mounting was prepared giving optimum motion ratio Metal bush was then attached Thus was completed. Before the modelling manual calculation was need to arrive at the design values for the tube that will be taken henceforth the design continued. It was also decided to use alloy steel for the whole setup.

- 84. 84 Analysis was don’t basically on two scenarios as they will be subjected to bending and side loading while cornering. Both for which results are plotted below. FIGURE 2 SHOWING MAXIMUM BENDING STRESS

- 85. 85 FIGURE 3 SIDE SKIDDING ANALYSIS 7. 2 Design of Rear Hub 7. 2.1 Introduction Rear wheel hub unlike front hub has an extra responsibility of transfer of torque. The stub axle is live and splined. The chief component in power train system for transmission of speed at a range of angle called as Constant Velocity (C.V) joint is directly engaged into rear hub. This requires the splines to be formed into hub that matches that of the respective C.V joint. Many vehicles uses hubs made of Cast iron, alloy steels. They are either made by casting or are forged to the required shape. Latte being producing strong components. Cast iron is usually preferred because of its cheap cost and worthy compressive strength. Many of the setup which uses the disk brake as their breaking setup has spacers that gaps brake disk and hub, this enable the space to host brake caliper in between. The setup is such that it makes servicing of brake disk easy and without removing whole of the assembly. 7. 2.3 Design parameter & Considerations Following are the Parameters which guided the design of Front Hubs,