Comparison evoh pvdc draft pdw august 2012 v1

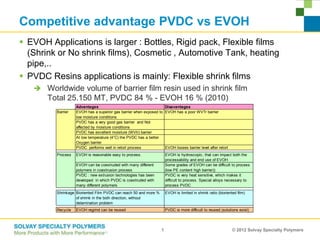

- 1. Competitive advantage PVDC vs EVOH EVOH Applications is larger : Bottles, Rigid pack, Flexible films (Shrink or No shrink films), Cosmetic , Automotive Tank, heating pipe,.. PVDC Resins applications is mainly: Flexible shrink films Worldwide volume of barrier film resin used in shrink film Total 25.150 MT, PVDC 84 % - EVOH 16 % (2010) Advantages Disavantages Barrier EVOH has a superior gas barrier when exposed to EVOH has a poor WVTr barrier low moisture conditions PVDC has a very good gas barrier and Not affected by moisture conditions PVDC has excellent moisture (WVtr) barrier At low temperature (4°C) the PVDC has a better Oxygen barrier PVDC performs well in retort process EVOH looses barrier level after retort Process EVOH is reasonable easy to process. EVOH is hydroscopic, that can impact both the processability and end use of EVOH EVOH can be coextruded with many different Some grades of EVOH can be difficult to process polymers in coextrusion process (low PE content high barrier)) PVDC : new extrusion technologies has been PVDC is very heat sensitive, which makes it developed in which PVDC is coextruded with difficult to process. Special alloys necessary to many different polymers process PVDC Shrinkage Bioriented Film PVDC can reach 50 and more % EVOH is limited in shrink ratio (bioriented film) of shrink in the both direction, without delamination problem Recycle EVOH regrind can be reused PVDC is more difficult to reused (solutions exist) 1 © 2012 Solvay Specialty Polymers

- 2. Competitive advantage PVDC vs EVOH Barrier for Oxygen and Water vapour Permeability of various polymers mainly in food packaging* * Film thickness: 1 µm (intrinsic permeability) Oxygen Water vapour Dry: 23°C/ 0% RH 38°C/ 90% RH cm³•µm/(m²•d•atm) g•µm/(m²•d) LDPE ca. 200,000 0 300 – 500 HDPE ca. 60,000 ca. 150 OPP ca. 50,000 100 – 200 R-PVC 2500 – 3000 600 – 900 cm³ [100um] / 1600d bar (23°C/0%RH) PA 6-6 m² – 2500 1000 – 2000 PETP ca. 1500 ca. 800 PVdC 8 – 230 6 – 80 PAN 100 – 300 1500 – 2000 EVOH (EVAL) 5 – 80 1500 – 3500 Cellophane 300 – 500 ca. 100,000 PVOH (PVAL) 3–4 > 500,000 0 2 © 2012 Solvay Specialty Polymers

- 3. Competitive advantage PVDC vs EVOH 1000 PVDC: a reliable barrier EVOH (29%mol. C2H4) EVOH (32%mol. C2H4) in humid conditions OTR at 20°C, cm³·µm/m2·d·atm) EVOH (44%mol. C2H4) N-MXD6 (bioriented film) N-MXD6 (cast film) 100 10 Barrier layer 90% RH PE PE 100% RH EVA EVA Inside [Data Sources: SolVin, Datasheet Nippon-Goshei] packaging 0.0025 80% RH 0% 20% 40% 60% 80% 100% Outside packaging Relative Humidity 3 © 2012 Solvay Specialty Polymers

- 4. Comparison EVOH and PVDC Barrier films prog 6477 : Optical microscopy 1 A (6477/2) PVDC 3 A ( 6477 / 4) EVOH Oxygen Barrier 5mocon Oxtram 2/20 4 layers : 7 / 10 / 7 / 40 µm 8 layers : 3 / 2 / 19 / 2 / 4 / 2 / 3 / 14 EVA / EVA / Copo VDC-MA / EVA PET / PE / PE / PE / PA / EVOH / PA / PE 23°C 23°C 11°C 5 °C (*) 85 % RH 0% RH 0% RH 0 % RH PVDC 1 7 7 2 0,9 PVDC 2 11 11 3 1,5 EVOH 1 6 7 3 2 EVOH 2 16 10 5 2,5 (*) external measurement Barrier properties PVDC and EVOH/PA Films 2 A (6477/3) PVDC 4 A (6477/4) EVOH 5 layers : 10 / 6 /10 / 14 / 15 µm 4 or 5 layers : 7 / 6 / 5 / 4 / 22 (layer 1 and 2 perhaps 1 layer) 12 PE / EVA / Copo VDC-MA / EVA / PE PA / PA / EVOH / PE / PE PVDC1 10 PVDC2 OTR, 0 % RH, cc/m² d b EVOH 1 EVOH2 8 6 4 2 0 0 5 10 15 20 25 Temperature, °C 4 © 2012 Solvay Specialty Polymers

- 5. Typical shrink curve Shrink (%) versus Temperature (°C) 70 60 50 Shrink (%) 40 transversal longitudinal 30 20 10 0 60 65 70 75 80 85 90 95 100 105 110 Temperature (°C) High shrink (up to 60 %) Homogeneous in both directions Tight vacuum packaging 5 © 2012 Solvay Specialty Polymers

- 6. Thickness and barrier integrity after shrink Microtome cut before shrink Microtome cut after shrink (scale = 20 µm) (scale = 50 µm) D A C E 100 °C D A 1s B 50 % shrink C B E 50 % shrink in both directions: PVDC thickness ©: 8 µm 32 µm Homogeneous thickness distribution preserved after shrink Intrinsic barrier maintained after shrink OTR at 25 °C, 85 % RH: 6.2 cc/m².d.bar 1.5 cc/m².d.bar Normalised for 1 µm: constant at 48 cc.µm/m².d.bar 6 © 2012 Solvay Specialty Polymers

- 7. New extrusion technology for multilayer blown film (No shrink film) Interest in multilayer blown films with PVDC has grown Can lead to a one-step process, eliminating laminations Use the advantages & benefits of PVDC for non-shrink applications The challenge: Larger dies are used (>20 cm), which extend the residence time inside the die, and can accelerate degradation 2 concepts to overcome this: Pre-encapsulation of PVDC by another resin which is thermally stable and compatible with PVDC. Macro Engineering Improved thermal insulation between layers Brampton Engineering 7 © 2012 Solvay Specialty Polymers

- 8. Pre-encapsulation technology Objective: minimize contact of PVDC with metal surface in the adaptor and die by early encapsulation “Early”: In the feed block before entering the die, or immediately after entering the die “Encapsulation” with EVA or EMA EVA max use = 240-250°C EMA max use = 300°C EMA has higher polarity (better compatibility with PVDC) Overlap in the die of about 10 cm Assure barrier layer Results Extended run time Extended die life Picture courtesy of Macro Engineering & Technology, Inc. 8 © 2012 Solvay Specialty Polymers

- 9. Exemple of structure PE done with Macro line LLDPE + LD/TL / PVS 100+ encapsulation / TL / Elite + LDPE thickness 40 µm Metric value Imperial value Water vapor transmission rate 38°C (100 °F) and 90 % RH 3 g/m² / day 0,2 g/100 in²/day Oxygen Transmission Rate 22°C (72°F) 0% RH 7 cm³/m² / day 0,5 cm³/100 in²/day Carbon dioxide Transmission Rate 22°C (72°F) 0% RH 28 cm³/m² / day 1,8 cm³/100 in²/day Nitrogen Transmission Rate 22°C (72°F) 0% RH 1 cm³/m² / day 0,1 cm³/100 in²/day Air Transmission Rate 22°C (72°F) 0% RH 2 cm³/m² / day 0,1 cm³/100 in²/day PVDC thickness 6 µm 0,2 mil Ultimate Tensile Strength ASTM D882 MD 27 MPa 3915 psi TD 20 MPa 2900 psi Ultimate elongation ASTM D882 MD 290 % 290 % TD 520 % 520 % 9 © 2012 Solvay Specialty Polymers

- 10. Improved thermal isolation Process structures requiring high T difference (+100°C) by increased T insulation within the die Proven coextrusion of PA 666 (skin layer) & PVDC; potential for PA 6 & PVDC Thermoforming applications Stackable die Easily extendable (inner outer) Easy maintenance Cross section of ISO-therm Die, courtesy Brampton Engineering, Inc. 10 © 2012 Solvay Specialty Polymers

- 11. Barrier after Retort (No Shrink film) Brampton Line Polymer Function Processing temperature Thickness µm PA 666 copolymer PA 6 and PA 6,6 (80/20) mechanical properties 245 - 250 °C 17 reduced cristallisation puncture resistance (PA limited to skin layer) better transparency thermoforming better BUR frost line shifted E MAH maleic anhydride reacts chemically with PA tie layer 215-225 °C 20 E is miscible with LDPE LDPE cost reduction 185 - 190 °C 24 EVA tie layer 185-190 °C 19 PVDC barrier 160 °C 31 EVA tie layer 185 - 190 °C 22 m LLDPE metalloscene LDPE sealing layer 215 - 225 °C 40 clarity, low temperature seal (blending ionomer is also an option) Total thickness (µm) 173 OTR @ 25 °C 1,2 cc/m2.d.b (dry and humid 85 %) 0,7 cc/m2.d.b after sterilisation similar film structure containing EVOH excellent OTR dry < 1 but increased > 10 cc/m2.d.b after sterilisation 11 © 2012 Solvay Specialty Polymers

- 12. Exemple of structure LDPE done with Brampton line ISO therm technology Brampton line trials and new resin development 6 layers : LDPE / EVA / EVA / IXAN Resin / EVA / LDPE 25 / 13 / 7 / 10 / 7 / 8 µm (Total 70 µm) Oxygen Barrier @ 23°C 85% RH 3,5 cc/m² d b 12 © 2012 Solvay Specialty Polymers