Kamishibai in practice

•Download as PPTX, PDF•

3 likes•9,195 views

For more information about Lean or Kamishibai: visit: www.panview.nl

Report

Share

Report

Share

Recommended

More Related Content

What's hot

What's hot (20)

Management Kamishibai Cards As A Tool To Sustain Lean Progress

Management Kamishibai Cards As A Tool To Sustain Lean Progress

Lean 5S Visual Workplace Organization Training Module

Lean 5S Visual Workplace Organization Training Module

More from Panview

More from Panview (20)

Kamishibai in practice

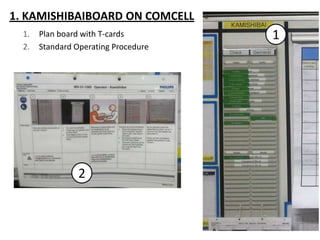

- 1. 1. KAMISHIBAIBOARD ON COMCELL 1. 2. Plan board with T-cards Standard Operating Procedure 2 1

- 2. 2. KAMISHIBAI T-CARDS 1. 2. 3. Two sides, Red and Green, containing the same text Each card contains a number of questions which you could ask during the Audit. There are general cards (the same on each workstation) and cards specifically for one particular workstation 1

- 3. 3. KAMISHIBAI TRACK SHEET 1. Visualize who has visited the gemba for a Kamishibai by using a tracksheet 1

- 4. 4. LINK BETWEEN KAMISHIBAI TO 3C / KAIZEN 1. 2. A red card always leads to a 3C Two possible actions with a red card: • Operator needs training in current standard (write on 3C only) • Improve the standard Kaizen! 1 2