More Related Content

Similar to Gmp checklist (20)

More from CCL Pharmaceuticals (20)

Gmp checklist

- 1. © 2007 Center for Pharmaceutical Learning

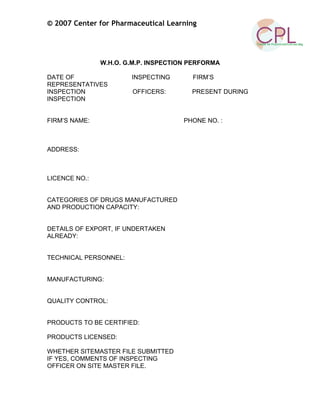

W.H.O. G.M.P. INSPECTION PERFORMA

DATE OF INSPECTING FIRM’S

REPRESENTATIVES

INSPECTION OFFICERS: PRESENT DURING

INSPECTION

FIRM’S NAME: PHONE NO. :

ADDRESS:

LICENCE NO.:

CATEGORIES OF DRUGS MANUFACTURED

AND PRODUCTION CAPACITY:

DETAILS OF EXPORT, IF UNDERTAKEN

ALREADY:

TECHNICAL PERSONNEL:

MANUFACTURING:

QUALITY CONTROL:

PRODUCTS TO BE CERTIFIED:

PRODUCTS LICENSED:

WHETHER SITEMASTER FILE SUBMITTED

IF YES, COMMENTS OF INSPECTING

OFFICER ON SITE MASTER FILE.

- 2. © 2007 Center for Pharmaceutical Learning

Complaint Yes/No Remark if non

complaint

1. PERSONNEL:

1.1 IS ORGANISATION CHART AVAILABLE:

1.2 ARE NO. OF PERSONNEL ADEQUATE:

1.3 NAME ,QUALIFICATION AND EXPERIENCE OF KEY

PERSONNEL(CHECK WITH SMF):

1.4 IS QUALIFICATION AND EXPERIENCE OF

PERSONNEL COMMENSURATE WITH JOB

DESCRIPTION:

1.5 IS MANAGERIAL RESPONCIBILITIES OF EACH

TECHNICAL PERSONNEL SPECIFIED IN WRITTING

WITH JOB DESCRIPTION:

1.6 CHECK WHETHER THERE ARE GAPS OR

UNEXPLAINED OVERLAP OF RESPONSIBILITIES

OF THE CONCERNED PERSONNEL:

2. TRAINING OF PERSONNEL:

2.1 IS WRITTEN PROGRAMME FOR TRAINING

AVAILABLE:

2.2 ARE ALL PERSONNEL TRAINED INITIALLY:

2.3 ARE PERIODICAL ASSESMENT RECORDS

AVAILABLE

2.4 IS SPECIAL PROGRAMME AVAILABLE FOR

PERSONNEL WORKING IN CLEAN AREAS AND

AREAS WHERE HIGHLY ACTIVE AND TOXIC

MATERIAL & HANDLED:

2.5 IS SOPs FOR TRAINING OF PERSONNEL

AVAILABLE:

3. PERSONNEL HYGIENE OF PERSONNEL:

3.1 ARE ALL PERSONNEL MEDICALLY EXAMINED

PRIOR TO = AND DURING EMPLOYMENT:

3.2 ARE THEY RESTRICTED , IF MEDICAL REASONS

DICTATE:

3.3 IS SOPs FOR CLOTHING AND HYGIENE

AVAILABLE:

- 3. © 2007 Center for Pharmaceutical Learning

3.4 ARE CLEAN UNIFORMS AND HAIR COVERING

CAPS USED:

3.5 CHECK NO. OF UNIFORMS PROVIDED. ARE

THEY ADEQUATE:

3.6 WHAT PROTECTIVE CLOTHING ARE PROVIDED

FOR VISITORS / OUTSIDE PERSONNEL

ENTERING IN PRODUCTION AREAS. ARE THEY

ADEQUATE:

4. PREMISES :

4.1 BRIEF DESCRIPTION OF BUILDING

4.2 IS DESIGNS AND CONSTRUCTED:

4.3 IS THE PREMISES COMPLY WITH SMF AND

SITUATED IN AN ENVIRONMENT WHICH CAUSED

MINIMUM RISK OF CONTAMINATION TO

MATERIALS OR PRODUCTS:

4.4 IS AREA PROVIDED COMMENSURATE WITH

PRODUCTION:

4.5 ARE NON MEDICAL PRODUCTS MANUFACTURED

IN THE PREMISES. IF YES, GIVE DETAILS:

4.6 ARE SOPs AVAILABLE FOR MAINTENANCE,

CLEANING AND SANITATION OF BUILDINGS,

PREMISES AND SURROUNDING

4.7 CHECK WHETHER THE AREA IS CLEANED AND

VALIDATED BEFORE STARTING STORING

/PROCESING /PACKING OPERATIONS:

4.8 IS ELECTRICAL SUPPLY,

LIGHTING,TEMPERATURE,HUMIDITY,AND

VENTILATION APPROPRIATE:

4.9 ARE ARRANGEMENT MADE FOR CONTROL OF

ENTRY OF RODENTS& BIRD

4.10 ARE FOLLOWING AREAS PROVIDED:

(A) SEPARATE REST ROOMS AND REFRESHMENT

ROOMS:

(B) SEPARATE CHANGING ROOMS AND TOILETS

FOR MALE AND FEMALE WORKERS:

(C) WORKSHOP IN A SEPARATE PLACE:

(D) ANIMAL HOUSES WITH SEPARATE ENTRY AND

AIR HANDLING UNIT:

5. STORAGE AREAS:

5.1 IS AREA SUFFICIENT FOR ORDERLY STORAGE

- 4. © 2007 Center for Pharmaceutical Learning

OF MATERIALS:

5.2 INDICATE AREAS FOR EACH CATEGORY AND

WHETHER BARRIERS ARE PROVIDED IF NOT,

EXPLAIN MODE OF SEGREGATION:

RAW MATERIALS:

QUARANTINE:

APPROVED:

REJECTED:

PACKING MATERIALS:

IS ACCESS TO QUARANTINE AREA

RESTRICTED:

5.4 ARE REJECTED GOODS MARKED AND STORED

SEPARATELY IN A SECURED AREA:

5.5 ARE RECORDS FOR ACTION TAKEN ON

REJECTED GOODS AVAILABLE:

5.6 ARE FACILITIES AVAILABLE FOR STORAGE IN

CONTROLLED TEMPERATURE/ HUMIDITY:

5.7 IS RECORD OF TEMPERATURE AND HUMIDITY

MAINTAINED:

5.8 ARE RECEIVING BAYS COVERED

5.9 ARE INCOMING MATERIALS CLEANED BEFORE

ENTRY TO STORAGE AREA:

5.10 IS SEPARATE SAMPLING AREA PROVIDED.IF ,

NOT HOW CONTAMINATION AND CROSS

CONTAMINATION IS PREVENTED:

5.11 ARE SENSITIVE MATERIALS/

HORMONES,BLACTUM, ANTIBIOTICS,

NARCOTICS,INFLAMMABLES, EXPLOSIVES

STORED IN SECURED AREA:

5.12 ARE PRINTED/CODED PACKING MATERIALS AND

CUT LABELS STORED IN SECURED AREA WITH

RESTRICTED ENTRY,AND WHETHER PACKING

MATERIALS LINE LABELS,CARTONS.LEAFLETS

ARE IN PIGEON HOLE, ALMIRAH:

5.13 IS DISPENSING AREA PROVIDED WITH DUST

- 5. © 2007 Center for Pharmaceutical Learning

CONTROL PROVISION:

5.14 DESCRIBE THE PRIMARY PACKING MATERIALS

STORAGE AREA:

6. PRODUCTION AREA:

6.1 ARE PRODUCTION AREAS FOR THE

FOLLOWINGS SEPARATED AND SELF CONTAIN.

DESCRIBE THE NATURE OF SEPARATION:

(A) BETA- LACTUM ANTIBIOTICS:

(B) HORMONES/CORTICOSTEROIDS

(C) OTHER DRUGS.

6.2 WHETHER THE ACCESS TO PRODUCTION AREA

RESTRICTED TO AUTHORISED PERSONNEL:

6.3 ARE WALLS, FLOORS AND CEILING SMOOTH AND

FREE FROM CRACKS:

6.4 IS THE PRODUCTION AREA WELL-LIT:

6.5 HOW CROSS CONTAMINATION OF STARTING

MATERIAL OR OF A PRODUCT BY ANOTHER

MATERIAL OR PRODUCT IS PREVENTED:

6.6 IS THE LAY OUT OF MANUFACTURING DIVISION

OF EACH CATEGORY OF DOSAGE FORM IN

LOGICAL SEQUENCE. IF NOT, GIVE DETAILS

WITH REFERENCE TO FLOOR PLAN:

6.7 IS WORKING SPACE ADEQUATE AND ATLEAST

ONE METER PROVIDED AROUND FOR EACH

EQUIPMENT:

6.8 ARE SERVICE LINES, LIGHT FITTINGS

CONCEALED AND FLUSHED TO THE SURFACE

OR MADE ACCESSIBLE FROM OUTSIDE. LOOK

FOR PROTRUDING SURFACE AND SPECIFY:

6.9 ARE DRAINE PROVIDED WITH TRAPS TO AVOID

BACK FLOW

6.10 ARE DRAINS CLEANED AND DISINFECTED

PERIODICALLY. CHECK RECORDS:

6.11 IS PRODUCTION AREA PROVIDED WITH PROPER

VENTILATION WITH AIRCONTROL FACILITIES

(FILTRATION, TEMPERATURE AND

HUMIDITY).ARE RECORDS MAINTAINED

- 6. © 2007 Center for Pharmaceutical Learning

THEREOF.

6.12 ARE LOCKERS PROVIDED FOR STORAGE OF

TOOLS AND PARTS:

6.13 ARE PACKAGING AND VISUAL INSPECTION

AREAS DESIGNED TO FACILITATE SEGREGATION

FOR EACH WORK LINE:

6.14 ARE EQUIPMENTS:

(A) LOCATED IN LOGICAL SEQUENCE (GIVE

BRIEF DESCRIPTION):

(B) DESIGNED, CONSTRUCTED TO SUIT THE

PURPOSE:

(C) PERMIT EFFECTIVE CLEANING:

(D) CLEANED BETWEEN BATCH OPERATION

AND RECORDED.CHECK RECORDS:

(E) CALLED TO INDICATE THEIR STATUS:

6.15 ARE SERVICE LINES PAINTED TO INDICATE THE

CONTENTS AND FLOW. RECORDS THE ORDER

SCHEME:

6.16 ARE BALANCES AND MEASURING EQUIPMENTS

CALIBRATED PERIODICALLY.CHECK RECORDS

AND PERIODICITY:

6.17 ARE WEIGHING EQUIPMENTS AND MEASURING

EQUIPMENTS OF APPROPRIATE RANGE AND

PRECISION AVAILABLE. CHECK CAPACITY OF

THE EQUIPMENT VIS-À-VIS BATCH SIZES OF

PRODUCTION:

6.18 CHECK THE TYPE OF WASHING AND CLEANING

EQUIPMENTS IN PRODUCTION AREA.(PARTICLE

GENERATING EQUIPMENTS SHOULD NOT BE

USED):

6.19 HOW DEFECTIVE EQUIPMENTS ARE

SEGREGATED:

7. MATERIALS:

7.1 IS SEGREGATION IS LOTWISE AND STOCK

ROTATION BY FIFO ADOPTED:

7.2 DOES PURCHASE DEPARTMENT STAFF

KNOWLEDGEABLE ABOUT THE PRODUCTS AND

MATERIALS:

7.3 HOW SUPPLIERS ARE SELECTED:

7.4 ARE SUPPLIERS EVALUATED AND APPROVED

AND THEIR NAME INCLUDED IN SPECIFICATION:

- 7. © 2007 Center for Pharmaceutical Learning

7.5 ARE PURCHASES MADE DIRECTLY FROM

PRODUCERS:

7.6 ARE MATERIALS CHECKED FOR INTEGRITY AND

CONFORMITY WITH ORDER ON RECEIPT:

7.7 IS DAMAGE RECORDED AND REPORTED TO

QUALITY CONTROL:

7.8 DO THE LABELS SHOW B.NO, NAME, C.R.NO. ,

STATUS,EXPIRY DATE , RETEST DATE

ETC.(COLLECT) SAMPLE OF INHOUSE LABELS):

7.9 IS COLOUR CODING SYSTEM USED TO INDICATE

STATUS:

7.10 ARE SAMPLE CONTAINERS IDENTIFIED AND

RELEASED:

7.11 ARE WRITTEN PRODUCERS FOR SAMPLING AND

DISPENSING AVAILABLE. COMPARE SOPs WITH

ACTUAL PRACTICE:

7.12 IS SAMPLING AND DISPENSING DONE BY

DESIGNATED PERSONS:

7.13 IS EACH DISPENSING CHECKED AND

RECORDED.

7.14 IS ADEQUATE STORAGE AREA FOR FINISHED

GOODS PROVIDED:

7.15 IS ADEQUATE AREA FOR RECALLED/RETURNED

PRODUCTS PROVIDED:

7.16 ARE PACKING MATERIALS CHECKED ON

DELIVERY AND ASSIGNED A SPECIFIC

REFERENCE NUMBER:

7.17 HOW THE WASTE MATERIALS FROM

STORE,PRODUCTION, QUALITYCONTROL

DISPOSED OFF:

7.18 IS THERE ACCUMULATION OF WASTE MATERIAL

AT ANY PART OF THE STORAGE/

PRODUCTION/Q.C.AREA:

8. DOCUMENTATION:

8.1 ARE ALL DOCUMENTS PREPARED AND

REVIEWED BY COMPETENT PERSONNEL

APPROVED AND SIGNED BY AUTHORISED

PERSONNEL:

8.2 ARE ALL DOCUMENTS PERIODICALLY REVISED:

8.3 ARE THE DOCUMENTS UNAMBIGUOUS CLEAR

EASY FOR REPRODUCTION AND EASY TO

CHECK:

- 8. © 2007 Center for Pharmaceutical Learning

8.4 IS THERE ANY ALTERATIONS, IN ENTRY MADE. IF

YES, ARE ALTERATIONS CLEAR, LEGIBLE AND

INITIALLED(OVER WRITING IS NOT PERMITTED):

8.5 ARE THE FOLLOWING DOCUMENTS AVAILABLE

WITH NECESSARY DETAILS:

(A) TESTING PROCEDURES FOR STARTING

MATERIALS, INTERMEDIATE PRODUCTS

AND FINISHED PRODUCTS,PACKING

MATERIALS:

(B) VALIDATION OF TESTING PROCEDURE:

(C) MASTER FORMULA CARD(COLLECT

SPECIMEN):

(D) PACKAGING INSTRUCTION (COLLECT

SPECIMEN):

(E) BATCH PROCESSING CARDS INCLUDING

INPROCESS CONTROLS.(COLLECT

SPECIMEN):

(F) BATCH PACKAGING CARD (COLLECT

SPECIMEN):

(G) REFERENCE STANDARDS:

(H) DISPOSAL RECORD OF OUTDATED

PRIMARY AND PRINTED PACKING

MATERIALS:

(I) RELEASE RECORDS:

(J) DISTRIBUTION RECORDS.(WITH WHAT

LEVEL):

(K) COMPARE MASTER FORMULA CARD WITH

- 9. © 2007 Center for Pharmaceutical Learning

ACTUAL PRACTICE:

8.6 ARE ALL RECORDS AND ASSOCIATED SOPs

RETAINED UPTO ONE YEAR AFTER EXPIRY OF

FINISHED PRODUCT:

8.7 ARE STANDARD OPERATING PROCEDURES FOR

THE FOLLOWING OPERATIONS AVAILABLE:

(A) RECEIPT MATERIALS:

(B) ENVIRONMENTAL MONITORING:

(C) INTERNAL LABELLING , QUARANTINE AND

STORAGE OF MATERIALS:

(D) EACH INSTRUMENT AND EQUIPMENT IN

THEIR PREXIMITY:

(E) EQUIPMENT ASSEMBLY AND VALIDATION:

(F) SAMPLING(RAW MATERIALS AND FINISHED

PRODUCTS):

(G) DISPENSING (RAW MATERIALS AND

PACKING MATERIALS):

(H) BATCH NUMBERING SYSTEM:

(I) RELEASE OR REJECTION:

(J) LOG BOOK FOR EACH EQUOPMENT AND

INSTRUMENT:

(K) SANITATION AND CLEANING OF PREMISES

AND EQUIPMENT:

(L) SANITATION OF PIPES CARRYING

DISTILLED/DEIONISED WATER:

- 10. © 2007 Center for Pharmaceutical Learning

(M)RECOVERY FROM REJECTED PRODUCTS:

(N) DISPOSAL/REUSE OF RETURNED GOODS:

(O) PEST CONTROL:

(P) ANALYTICAL APPARATUS AND

CALIBRATION:

(Q) COMPLAINTS,RECALLS AND RETURNS:

(R) COMPARE SOPs WITH ACTUAL PRACTICE:

9. PRODUCTION:

9.1 IS THERE ANY DEVIATION FROM SOPs

MANUFACTURING PROCEDURES:

9.2 IS YIELD CHECKED AT EACH STAGE:

9.3 IS MORE THAN ONE PRODUCT PROCESSED IN

THE SAME ROOM:

9.4 ARE EQUIPMENTS AND ROOMS LABELLED TO

INDICATE THE OPERATION IN PROGRESS:

9.5 IS ANY NON MEDICAL PRODUCT PRODUCED.

SPECIFY THE DETAILS:

9.6 IS THERE PROVISION FOR INPROCESS

CONTROLS IN THE PRODUCTION AREA(MUST

NOT EFFECT THE QUALITY OF THE PRIODUCTS

MANUFACTURED):

9.7 IS THERE PROVISION FOR DUST COLLECTION

WHERE DRY MATERIALS ARE HANDLED:

9.8 IS PERIODICAL MICROBIAL MONITORING OF

PRODUCTION AREAS OF SUCEPTIBLE PRODUCTS

CONDUCTED:

9.9 WAS THE AREA BEING CLEANED BEFORE

STARTING EVERY BATCH:

9.10 ARE PIPES CARRYING DISTILLED/DEIONISED

WATER SANITIZED ACCORDING TO PROCEDURE

WHICH INDICATE LIMITS FOR MICROBIAL

CONTAMINATION AND MEASURES TO BE TAKEN:

9.11 WAS ANY BATCH REPROCESSED FROM

- 11. © 2007 Center for Pharmaceutical Learning

REJECTED PRODUCTS:

9.12 WAS ANY BATCH RETURNED HAS BEEN

CONVERTED FOR RESALE , RELABELLING OR

BULKING:

10. PACKAGING:

10.1 IS THERE ADEQUATE SEPARATION OF PACKING

LINES TO PREVENT ANY MIX-UP:

10.2 IS EACH PACKAGING LINE IDENTIFIED WITH

PRODUCT NAME, BATCH NO. AND PACKAGING

SIZE:

10.3 IS ONLY ONE PRODUCT, BATCH AND PACKAGING

SIZE ON A LINE AT ANY GIVEN TIME:

10.4 IS LINE CLEARED BEFORE EACH BATCH

OPERATION,CERTIFIED AND RECORDED:

10.5 DOES PACKING QUICKLY FOLLOWS THE FILLING

AND SEALING:

10.6 ARE ALL CODED PACKING MATERIALS VERIFIED

BEFORE USE.

10.7 IS RECONCILATION OF PACKING MATERIALS

USED VIS-À-VIS PRODUCT RECORDED:

10.8 IS ON LINE COTROL PROCEDURE DURING

PACKING AVAILABLE:

11. QUALITY CONTROL:

11.1 HOW FAR THE HEAD OF QUALITY CONTROL

AND PRODUCTION ARE INDEPENDENT OF EACH

OTHER:

11.2 ARE ALL THE PROCEDURES OF

DOCUMEBNTED:

11.3 IS SAMPLING PROCEDURE ADEQUATE:

11.4 DO THE LABEL ON SAMPLE CONTAINER, SHOW

BATCH NO. , NAME,CONTAINER NO., DATE OF

SAMPLING AND PERSON WHO SAMPLED:

11.5 IS IDENTIFY TEST DONE ON EACH CONTAINER

OF STARTING MATERIALS:

11.6 ARE ANALYTICAL RECORDS OF EACH BATCH

OF THE RAW MATERIALS,INTERMEDIATES AND

FINISHED PRODUCTS AVAILABLE WITH WORK

SHEETS:

11.7 ARE PRODUCTION RECORDS REVIEWED:

11.8 ARE ALL RETENTION SAMPLES KEPT FOR ONE

YEAR AFTER EXPIRY DATE AND OTHER

- 12. © 2007 Center for Pharmaceutical Learning

STARTING MATERIALS FOR A MINIMUM OF TWO

YEARS:

11.9 IS PROGRAMME FOR STABILITY TESTING OF

STARTING MATERIALS AND FINISHED

PRODUCTS AVAILABLE:

11.10 IS STABILITY TESTING CONDUCTED PRIOR TO

MARKETING AND AFTER CHANGE OF PROCESS

EQUIPMENT,PACKING MATERIALS:

11.11 IS QUALITY CONTROL LAB SEPARATE FROM

PRODUCTION AREA:

11.12 ARE BIOLOGICAL AND MICROBIOLOGICAL

TESTING AREAS SEPARATE FROM EACH

OTHER,AND DO THEY HAVE SEPARATE AIR

HANDLING FACILITIES:

11.13 IS INSTRUMENT ROOM SEPARATE:

11.14 IS DESIGN OF LAB SUITABLE WITH ADEQUATE

SPACE,VENTILATION AND FOR PREVENTION OF

FUMES:

11.15 ARE RECORDS OF SERVICE AND CALIBRATION

OF INSTRUMENT AVAILABLE:

11.16 ARE APPROPRIATE SAMPLING EQUIPMENT

AVAILABLE AND STARTED SEPARATELY:

11.17 ARE INSTRUMENTS CHECKED DAILY OR PRIOR

TO USE:

11.18 ARE DATE OF CALIBRATION , SERVICE ,AND

DATE WHEN RECALIBRATION DUE INDICATED:

11.19 ARE THE REAGENTS PREPARED ACCORDING

TO WRITTEN PROCEDURES AND LABELLED

APPROPRIATELY:

11.20 ARE REFERENCE STANDARDS AVAILABLE

CORRESPOND TO THE MATERIALS ANALYSED:

11.21 IS ADEQUATE STORAGE SPACE (IF NECESSARY

WITH COOLING) AND RECORDS ARE AVAILABLE

FOR REFERENCE STANDARDS AND

REFERENCE SAMPLES. CHECK THE MODE OF

STORAGE OF REFERENCE STANDARDS:

11.22 ARE WORKING STANDARDS CHECKED AT

REGULAR INTERVALS:

11.23 ARE THE LABELS OF REF. STANDARDS

INDICATE NAME, DATE OF MFG. DATE OF

EXPIRY,CONCENTRATION AND DATE OF

CLOSURE IS FIRST OPENED AND STORAGE

CONDITIONS:

- 13. © 2007 Center for Pharmaceutical Learning

11.24 ARE THE LABEL OF REAGENTS PREPARED

SHOW CONCENTRATION , STANDARDISATION

FACTOR, SELF- LIFE,STANDARDISATION DATE

,STORAGE CONDITION AND SIGNATURE OF THE

PERSON PREPARES THE REAGENTS:

11.25 ARE POSITIVE AND NEGATIVE CONTROLS USED

TO TEST SUITABILITY OF CULTURE MEDIA:

11.26 ARE STABILITY STUDIES CONDUCTED BEFORE

ASSIGNING SHELF LIFE AND IS IT PERIODICALL

REVIEWED, AND GIVE DETAILS:

12. SELF INSPECTION:

GIVE DETAILS OF NAMES,

QUALIFICATION AND BACKGROUND

OF THE MEMBERS OF SELF

INSPECTION TEAM:

12.1 INTERVAL PERIOD BETWEEN SELF

INSPECTIONS:

12.2 DOES SELF INSPECTION REPORT CONTAINS

COMMENTS ON:

(A) PERSONNEL:

(B) PREMISES:

(C) MAINTENANCE OF BUILDING AND

EQUIPMENT:

(D) STORAGE:

(E) EQUIPMENT:

(F) PRODUCTION AND INPROCESS

CONTROL:

(G)QUALITY CONTROL:

(H) DOCUMENTATION:

- 14. © 2007 Center for Pharmaceutical Learning

(I) SANITATION AND HYGIENE:

(J) VALIDATION PROCEDURE /

PROGRAMMES:

(K) CALIBRATION OF INSTRUMENTS:

(L) RECALL PROCEDURES:

(M)LABELS CONTROL:

(N) COMPLAINTS:

(O)CORRECTIVE ACTION ON PREVIOUS

REPORTS:

13 RECALL PROCEDURE :

EXPLAIN PROCEDURE ADOPTED FOR RECALL

OF PRODUCTS:

14 QUALITY AUDIT SYSTEM :

(BRIEF RESPONSIBILITIES

REMARKS:

1.1 IS ORGANISATION CHART

AVAILABLE:

1.2 ARE NO. OF PERSONNEL

ADEQUATE:

1.3 NAME ,QUALIFICATION AND

EXPERIENCE OF KEY

PERSONNEL(CHECK WITH SMF):

1.4 IS QUALIFICATION AND

EXPERIENCE OF PERSONNEL

COMMENSURATE WITH JOB

DESCRIPTION:

1.5 IS MANAGERIAL

RESPONCIBILITIES OF EACH

- 15. © 2007 Center for Pharmaceutical Learning

TECHNICAL PERSONNEL

SPECIFIED IN WRITTING WITH

JOB DESCRIPTION:

1.6 CHECK WHETHER THERE ARE

GAPS OR UNEXPLAINED

OVERLAP OF RESPONSIBILITIES

OF THE CONCERNED

PERSONNEL:

2. TRAINING OF PERSONNEL:

2.1 IS WRITTEN PROGRAMME FOR

TRAINING AVAILABLE:

2.2 ARE ALL PERSONNEL TRAINED

INITIALLY:

2.3 ARE PERIODICAL ASSESMENT

RECORDS AVAILABLE

2.4 IS SPECIAL PROGRAMME

AVAILABLE FOR PERSONNEL

WORKING IN CLEAN AREAS

AND AREAS WHERE HIGHLY

ACTIVE AND TOXIC MATERIAL

& HANDLED:

2.5 IS SOPs FOR TRAINING OF

PERSONNEL AVAILABLE:

3. PERSONNEL HYGIENE OF PERSONNEL:

3.1 ARE ALL PERSONNEL

MEDICALLY EXAMINED PRIOR TO

= AND DURING EMPLOYMENT:

3.2 ARE THEY RESTRICTED , IF

MEDICAL REASONS DICTATE:

3.3 IS SOPs FOR CLOTHING AND

HYGIENE AVAILABLE:

3.4 ARE CLEAN UNIFORMS AND HAIR

COVERING CAPS USED:

3.5 CHECK NO. OF UNIFORMS

- 16. © 2007 Center for Pharmaceutical Learning

PROVIDED. ARE THEY

ADEQUATE:

3.6 WHAT PROTECTIVE CLOTHING

ARE PROVIDED FOR VISITORS /

OUTSIDE PERSONNEL ENTERING

IN PRODUCTION AREAS. ARE

THEY ADEQUATE:

6. PREMISES :

4.1 BRIEF DESCRIPTION OF BUILDING

4.2 IS DESIGNS AND CONSTRUCTED:

4.3 IS THE PREMISES COMPLY WITH SMF

AND SITUATED IN AN ENVIRONMENT

WHICH CAUSED MINIMUM RISK OF

CONTAMINATION TO MATERIALS OR

PRODUCTS:

4.4 IS AREA PROVIDED COMMENSURATE

WITH PRODUCTION:

4.5 ARE NON MEDICAL PRODUCTS

MANUFACTURED IN THE PREMISES. IF

YES, GIVE DETAILS:

4.6 ARE SOPs AVAILABLE FOR

MAINTENANCE, CLEANING AND

SANITATION OF BUILDINGS, PREMISES

AND SURROUNDING

4.7 CHECK WHETHER THE AREA IS CLEANED

AND VALIDATED BEFORE STARTING

STORING /PROCESING /PACKING

OPERATIONS:

4.8 IS ELECTRICAL SUPPLY,

LIGHTING,TEMPERATURE,HUMIDITY,AND

VENTILATION APPROPRIATE:

4.9 ARE ARRANGEMENT MADE FOR

CONTROL OF ENTRY OF RODENTS& BIRD

4.10 ARE FOLLOWING AREAS PROVIDED:

(A) SEPARATE REST ROOMS AND

REFRESHMENT ROOMS:

(B) SEPARATE CHANGING ROOMS

AND TOILETS FOR MALE AND

- 17. © 2007 Center for Pharmaceutical Learning

FEMALE WORKERS:

(C) WORKSHOP IN A SEPARATE

PLACE:

(D) ANIMAL HOUSES WITH

SEPARATE ENTRY AND AIR

HANDLING UNIT:

7. STORAGE AREAS:

5.1 IS AREA SUFFICIENT FOR

ORDERLY STORAGE OF

MATERIALS:

5.2 INDICATE AREAS FOR EACH

CATEGORY AND WHETHER

BARRIERS ARE PROVIDED IF

NOT, EXPLAIN MODE OF

SEGREGATION:

RAW MATERIALS:

QUARANTINE:

APPROVED:

REJECTED:

PACKING MATERIALS:

IS ACCESS TO QUARANTINE

AREA RESTRICTED:

5.4 ARE REJECTED GOODS

MARKED AND STORED

SEPARATELY IN A SECURED

AREA:

5.5 ARE RECORDS FOR ACTION

TAKEN ON REJECTED GOODS

AVAILABLE:

5.6 ARE FACILITIES AVAILABLE

FOR STORAGE IN

- 18. © 2007 Center for Pharmaceutical Learning

CONTROLLED TEMPERATURE/

HUMIDITY:

5.7 IS RECORD OF TEMPERATURE

AND HUMIDITY MAINTAINED:

5.8 ARE RECEIVING BAYS

COVERED

5.9 ARE INCOMING MATERIALS

CLEANED BEFORE ENTRY TO

STORAGE AREA:

5.10 IS SEPARATE SAMPLING AREA

PROVIDED.IF , NOT HOW

CONTAMINATION AND CROSS

CONTAMINATION IS

PREVENTED:

5.11 ARE SENSITIVE MATERIALS/

HORMONES,BLACTUM,

ANTIBIOTICS,

NARCOTICS,INFLAMMABLES,

EXPLOSIVES STORED IN

SECURED AREA:

5.12 ARE PRINTED/CODED

PACKING MATERIALS AND

CUT LABELS STORED IN

SECURED AREA WITH

RESTRICTED ENTRY,AND

WHETHER PACKING

MATERIALS LINE

LABELS,CARTONS.LEAFLETS

ARE IN PIGEON HOLE,

ALMIRAH:

5.13 IS DISPENSING AREA

PROVIDED WITH DUST

CONTROL PROVISION:

5.14 DESCRIBE THE PRIMARY

PACKING MATERIALS

STORAGE AREA:

7. PRODUCTION AREA:

- 19. © 2007 Center for Pharmaceutical Learning

6.1 ARE PRODUCTION AREAS FOR THE

FOLLOWINGS SEPARATED AND SELF

CONTAIN. DESCRIBE THE NATURE OF

SEPARATION:

(D) BETA- LACTUM ANTIBIOTICS:

(E) HORMONES/CORTICOSTEROIDS

(F) OTHER DRUGS.

6.2 WHETHER THE ACCESS TO

PRODUCTION AREA RESTRICTED TO

AUTHORISED PERSONNEL:

6.3 ARE WALLS, FLOORS AND CEILING

SMOOTH AND FREE FROM CRACKS:

6.4 IS THE PRODUCTION AREA WELL-LIT:

6.5 HOW CROSS CONTAMINATION

OF STARTING MATERIAL OR

OF A PRODUCT BY ANOTHER

MATERIAL OR PRODUCT IS

PREVENTED:

6.6 IS THE LAY OUT OF

MANUFACTURING DIVISION

OF EACH CATEGORY OF

DOSAGE FORM IN LOGICAL

SEQUENCE. IF NOT, GIVE

DETAILS WITH REFERENCE TO

FLOOR PLAN:

6.7 IS WORKING SPACE

ADEQUATE AND ATLEAST

ONE METER PROVIDED

AROUND FOR EACH

EQUIPMENT:

6.8 ARE SERVICE LINES, LIGHT

FITTINGS CONCEALED AND

FLUSHED TO THE SURFACE OR

MADE ACCESSIBLE FROM

OUTSIDE. LOOK FOR

PROTRUDING SURFACE AND

SPECIFY:

6.9 ARE DRAINE PROVIDED WITH

- 20. © 2007 Center for Pharmaceutical Learning

TRAPS TO AVOID BACK FLOW

6.10 ARE DRAINS CLEANED AND

DISINFECTED PERIODICALLY.

CHECK RECORDS:

6.11 IS PRODUCTION AREA

PROVIDED WITH PROPER

VENTILATION WITH

AIRCONTROL FACILITIES

(FILTRATION, TEMPERATURE

AND HUMIDITY).ARE

RECORDS MAINTAINED

THEREOF.

6.12 ARE LOCKERS PROVIDED FOR

STORAGE OF TOOLS AND

PARTS:

6.13 ARE PACKAGING AND VISUAL

INSPECTION AREAS DESIGNED

TO FACILITATE SEGREGATION

FOR EACH WORK LINE:

6.14 ARE EQUIPMENTS:

(F) LOCATED IN LOGICAL

SEQUENCE (GIVE BRIEF

DESCRIPTION):

(G) DESIGNED,

CONSTRUCTED TO SUIT

THE PURPOSE:

(H) PERMIT EFFECTIVE

CLEANING:

(I) CLEANED BETWEEN

BATCH OPERATION AND

RECORDED.CHECK

RECORDS:

(J) CALLED TO INDICATE

THEIR STATUS:

6.15 ARE SERVICE LINES PAINTED

TO INDICATE THE CONTENTS

AND FLOW. RECORDS THE

ORDER SCHEME:

6.16 ARE BALANCES AND

- 21. © 2007 Center for Pharmaceutical Learning

MEASURING EQUIPMENTS

CALIBRATED

PERIODICALLY.CHECK

RECORDS AND PERIODICITY:

6.17 ARE WEIGHING EQUIPMENTS

AND MEASURING

EQUIPMENTS OF APPROPRIATE

RANGE AND PRECISION

AVAILABLE. CHECK

CAPACITY OF THE EQUIPMENT

VIS-À-VIS BATCH SIZES OF

PRODUCTION:

6.18 CHECK THE TYPE OF WASHING

AND CLEANING EQUIPMENTS

IN PRODUCTION

AREA.(PARTICLE GENERATING

EQUIPMENTS SHOULD NOT BE

USED):

6.19 HOW DEFECTIVE EQUIPMENTS

ARE SEGREGATED:

8. MATERIALS:

7.1 IS SEGREGATION IS LOTWISE

AND STOCK ROTATION BY

FIFO ADOPTED:

7.2 DOES PURCHASE

DEPARTMENT STAFF

KNOWLEDGEABLE ABOUT

THE PRODUCTS AND

MATERIALS:

7.3 HOW SUPPLIERS ARE

SELECTED:

7.4 ARE SUPPLIERS EVALUATED

AND APPROVED AND THEIR

NAME INCLUDED IN

SPECIFICATION:

7.5 ARE PURCHASES MADE

DIRECTLY FROM PRODUCERS:

7.6 ARE MATERIALS CHECKED

FOR INTEGRITY AND

CONFORMITY WITH ORDER ON

RECEIPT:

- 22. © 2007 Center for Pharmaceutical Learning

7.7 IS DAMAGE RECORDED AND

REPORTED TO QUALITY

CONTROL:

7.8 DO THE LABELS SHOW B.NO,

NAME, C.R.NO. ,

STATUS,EXPIRY DATE ,

RETEST DATE ETC.(COLLECT)

SAMPLE OF INHOUSE LABELS):

7.9 IS COLOUR CODING SYSTEM

USED TO INDICATE STATUS:

7.10 ARE SAMPLE CONTAINERS

IDENTIFIED AND RELEASED:

7.11 ARE WRITTEN PRODUCERS

FOR SAMPLING AND

DISPENSING AVAILABLE.

COMPARE SOPs WITH ACTUAL

PRACTICE:

7.12 IS SAMPLING AND DISPENSING

DONE BY DESIGNATED

PERSONS:

7.13 IS EACH DISPENSING

CHECKED AND RECORDED.

7.14 IS ADEQUATE STORAGE AREA

FOR FINISHED GOODS

PROVIDED:

7.15 IS ADEQUATE AREA FOR

RECALLED/RETURNED

PRODUCTS PROVIDED:

7.16 ARE PACKING MATERIALS

CHECKED ON DELIVERY AND

ASSIGNED A SPECIFIC

REFERENCE NUMBER:

7.17 HOW THE WASTE MATERIALS

FROM STORE,PRODUCTION,

QUALITYCONTROL DISPOSED

OFF:

7.18 IS THERE ACCUMULATION OF

WASTE MATERIAL AT ANY

PART OF THE STORAGE/

PRODUCTION/Q.C.AREA:

- 23. © 2007 Center for Pharmaceutical Learning

9. DOCUMENTATION:

8.1 ARE ALL DOCUMENTS

PREPARED AND REVIEWED BY

COMPETENT PERSONNEL

APPROVED AND SIGNED BY

AUTHORISED PERSONNEL:

8.2 ARE ALL DOCUMENTS

PERIODICALLY REVISED:

8.3 ARE THE DOCUMENTS

UNAMBIGUOUS CLEAR EASY

FOR REPRODUCTION AND

EASY TO CHECK:

8.4 IS THERE ANY ALTERATIONS,

IN ENTRY MADE. IF YES, ARE

ALTERATIONS CLEAR,

LEGIBLE AND

INITIALLED(OVER WRITING IS

NOT PERMITTED):

8.5 ARE THE FOLLOWING

DOCUMENTS AVAILABLE WITH

NECESSARY DETAILS:

(L) TESTING PROCEDURES

FOR STARTING

MATERIALS,

INTERMEDIATE PRODUCTS

AND FINISHED

PRODUCTS,PACKING

MATERIALS:

(M)VALIDATION OF TESTING

PROCEDURE:

(N) MASTER FORMULA

CARD(COLLECT

SPECIMEN):

(O) PACKAGING INSTRUCTION

(COLLECT SPECIMEN):

- 24. © 2007 Center for Pharmaceutical Learning

(P) BATCH PROCESSING

CARDS INCLUDING

INPROCESS

CONTROLS.(COLLECT

SPECIMEN):

(Q) BATCH PACKAGING CARD

(COLLECT SPECIMEN):

(R) REFERENCE STANDARDS:

(S) DISPOSAL RECORD OF

OUTDATED PRIMARY AND

PRINTED PACKING

MATERIALS:

(T) RELEASE RECORDS:

(U) DISTRIBUTION

RECORDS.(WITH WHAT

LEVEL):

(V) COMPARE MASTER

FORMULA CARD WITH

ACTUAL PRACTICE:

8.6 ARE ALL RECORDS AND

ASSOCIATED SOPs RETAINED

UPTO ONE YEAR AFTER EXPIRY

OF FINISHED PRODUCT:

8.7 ARE STANDARD OPERATING

PROCEDURES FOR THE

FOLLOWING OPERATIONS

AVAILABLE:

(S) RECEIPT MATERIALS:

(T) ENVIRONMENTAL

MONITORING:

- 25. © 2007 Center for Pharmaceutical Learning

(U) INTERNAL LABELLING ,

QUARANTINE AND

STORAGE OF MATERIALS:

(V) EACH INSTRUMENT AND

EQUIPMENT IN THEIR

PREXIMITY:

(W)EQUIPMENT ASSEMBLY

AND VALIDATION:

(X) SAMPLING(RAW

MATERIALS AND FINISHED

PRODUCTS):

(Y) DISPENSING (RAW

MATERIALS AND PACKING

MATERIALS):

(Z) BATCH NUMBERING

SYSTEM:

(AA)RELEASE OR REJECTION:

(BB)LOG BOOK FOR EACH

EQUOPMENT AND

INSTRUMENT:

(CC)SANITATION AND

CLEANING OF PREMISES

AND EQUIPMENT:

(DD)SANITATION OF PIPES

CARRYING

DISTILLED/DEIONISED

WATER:

- 26. © 2007 Center for Pharmaceutical Learning

(EE)RECOVERY FROM

REJECTED PRODUCTS:

(FF)DISPOSAL/REUSE OF

RETURNED GOODS:

(GG)PEST CONTROL:

(HH)ANALYTICAL APPARATUS

AND CALIBRATION:

(II) COMPLAINTS,RECALLS

AND RETURNS:

(JJ) COMPARE SOPs WITH

ACTUAL PRACTICE:

11. PRODUCTION:

9.1 IS THERE ANY DEVIATION

FROM SOPs MANUFACTURING

PROCEDURES:

9.2 IS YIELD CHECKED AT EACH

STAGE:

9.3 IS MORE THAN ONE PRODUCT

PROCESSED IN THE SAME

ROOM:

9.4 ARE EQUIPMENTS AND ROOMS

LABELLED TO INDICATE THE

OPERATION IN PROGRESS:

9.5 IS ANY NON MEDICAL

PRODUCT PRODUCED. SPECIFY

THE DETAILS:

9.6 IS THERE PROVISION FOR

INPROCESS CONTROLS IN THE

PRODUCTION AREA(MUST NOT

EFFECT THE QUALITY OF THE

PRIODUCTS MANUFACTURED):

9.7 IS THERE PROVISION FOR

- 27. © 2007 Center for Pharmaceutical Learning

DUST COLLECTION WHERE

DRY MATERIALS ARE

HANDLED:

9.8 IS PERIODICAL MICROBIAL

MONITORING OF PRODUCTION

AREAS OF SUCEPTIBLE

PRODUCTS CONDUCTED:

9.9 WAS THE AREA BEING

CLEANED BEFORE STARTING

EVERY BATCH:

9.10 ARE PIPES CARRYING

DISTILLED/DEIONISED WATER

SANITIZED ACCORDING TO

PROCEDURE WHICH INDICATE

LIMITS FOR MICROBIAL

CONTAMINATION AND

MEASURES TO BE TAKEN:

9.11 WAS ANY BATCH

REPROCESSED FROM

REJECTED PRODUCTS:

9.12 WAS ANY BATCH RETURNED

HAS BEEN CONVERTED FOR

RESALE , RELABELLING OR

BULKING:

12. PACKAGING:

10.1 IS THERE ADEQUATE

SEPARATION OF PACKING

LINES TO PREVENT ANY MIX-

UP:

10.2 IS EACH PACKAGING LINE

IDENTIFIED WITH PRODUCT

NAME, BATCH NO. AND

PACKAGING SIZE:

10.3 IS ONLY ONE PRODUCT,

BATCH AND PACKAGING SIZE

ON A LINE AT ANY GIVEN

TIME:

10.4 IS LINE CLEARED BEFORE

EACH BATCH

OPERATION,CERTIFIED AND

RECORDED:

10.5 DOES PACKING QUICKLY

- 28. © 2007 Center for Pharmaceutical Learning

FOLLOWS THE FILLING AND

SEALING:

10.6 ARE ALL CODED PACKING

MATERIALS VERIFIED BEFORE

USE.

10.7 IS RECONCILATION OF

PACKING MATERIALS USED

VIS-À-VIS PRODUCT

RECORDED:

10.8 IS ON LINE COTROL

PROCEDURE DURING PACKING

AVAILABLE:

13. QUALITY CONTROL:

11.1 HOW FAR THE HEAD OF

QUALITY CONTROL AND

PRODUCTION ARE

INDEPENDENT OF EACH OTHER:

11.2 ARE ALL THE PROCEDURES OF

DOCUMEBNTED:

11.3 IS SAMPLING PROCEDURE

ADEQUATE:

11.4 DO THE LABEL ON SAMPLE

CONTAINER, SHOW BATCH NO. ,

NAME,CONTAINER NO., DATE

OF SAMPLING AND PERSON

WHO SAMPLED:

11.5 IS IDENTIFY TEST DONE ON

EACH CONTAINER OF STARTING

MATERIALS:

11.6 ARE ANALYTICAL RECORDS OF

EACH BATCH OF THE RAW

MATERIALS,INTERMEDIATES

AND FINISHED PRODUCTS

AVAILABLE WITH WORK

SHEETS:

11.7 ARE PRODUCTION RECORDS

REVIEWED:

11.8 ARE ALL RETENTION SAMPLES

KEPT FOR ONE YEAR AFTER

EXPIRY DATE AND OTHER

- 29. © 2007 Center for Pharmaceutical Learning

STARTING MATERIALS FOR A

MINIMUM OF TWO YEARS:

11.9 IS PROGRAMME FOR STABILITY

TESTING OF STARTING

MATERIALS AND FINISHED

PRODUCTS AVAILABLE:

11.10 IS STABILITY TESTING

CONDUCTED PRIOR TO

MARKETING AND AFTER

CHANGE OF PROCESS

EQUIPMENT,PACKING

MATERIALS:

11.11 IS QUALITY CONTROL LAB

SEPARATE FROM PRODUCTION

AREA:

11.12 ARE BIOLOGICAL AND

MICROBIOLOGICAL TESTING

AREAS SEPARATE FROM EACH

OTHER,AND DO THEY HAVE

SEPARATE AIR HANDLING

FACILITIES:

11.13 IS INSTRUMENT ROOM

SEPARATE:

11.14 IS DESIGN OF LAB SUITABLE

WITH ADEQUATE

SPACE,VENTILATION AND FOR

PREVENTION OF FUMES:

11.15 ARE RECORDS OF SERVICE AND

CALIBRATION OF INSTRUMENT

AVAILABLE:

11.16 ARE APPROPRIATE SAMPLING

EQUIPMENT AVAILABLE AND

STARTED SEPARATELY:

11.17 ARE INSTRUMENTS CHECKED

DAILY OR PRIOR TO USE:

11.18 ARE DATE OF CALIBRATION ,

SERVICE ,AND DATE WHEN

RECALIBRATION DUE

INDICATED:

11.19 ARE THE REAGENTS PREPARED

ACCORDING TO WRITTEN

PROCEDURES AND LABELLED

APPROPRIATELY:

- 30. © 2007 Center for Pharmaceutical Learning

11.20 ARE REFERENCE STANDARDS

AVAILABLE CORRESPOND TO

THE MATERIALS ANALYSED:

11.21 IS ADEQUATE STORAGE SPACE

(IF NECESSARY WITH COOLING)

AND RECORDS ARE AVAILABLE

FOR REFERENCE STANDARDS

AND REFERENCE SAMPLES.

CHECK THE MODE OF STORAGE

OF REFERENCE STANDARDS:

11.22 ARE WORKING STANDARDS

CHECKED AT REGULAR

INTERVALS:

11.23 ARE THE LABELS OF REF.

STANDARDS INDICATE NAME,

DATE OF MFG. DATE OF

EXPIRY,CONCENTRATION AND

DATE OF CLOSURE IS FIRST

OPENED AND STORAGE

CONDITIONS:

11.24 ARE THE LABEL OF REAGENTS

PREPARED SHOW

CONCENTRATION ,

STANDARDISATION FACTOR,

SELF- LIFE,STANDARDISATION

DATE ,STORAGE CONDITION

AND SIGNATURE OF THE

PERSON PREPARES THE

REAGENTS:

11.25 ARE POSITIVE AND NEGATIVE

CONTROLS USED TO TEST

SUITABILITY OF CULTURE

MEDIA:

11.26 ARE STABILITY STUDIES

CONDUCTED BEFORE

ASSIGNING SHELF LIFE AND IS

IT PERIODICALL REVIEWED,

AND GIVE DETAILS:

14. SELF INSPECTION:

- 31. © 2007 Center for Pharmaceutical Learning

GIVE DETAILS OF NAMES,

QUALIFICATION AND BACKGROUND

OF THE MEMBERS OF SELF

INSPECTION TEAM:

12.1 INTERVAL PERIOD BETWEEN

SELF INSPECTIONS:

12.2 DOES SELF INSPECTION REPORT

CONTAINS COMMENTS ON:

(P) PERSONNEL:

(Q) PREMISES:

(R) MAINTENANCE OF

BUILDING AND

EQUIPMENT:

(S) STORAGE:

(T) EQUIPMENT:

(U) PRODUCTION AND

INPROCESS CONTROL:

(V) QUALITY CONTROL:

(W)DOCUMENTATION:

(X) SANITATION AND

HYGIENE:

(Y) VALIDATION PROCEDURE

/ PROGRAMMES:

(Z) CALIBRATION OF

INSTRUMENTS:

- 32. © 2007 Center for Pharmaceutical Learning

(AA)RECALL PROCEDURES:

(BB)LABELS CONTROL:

(CC)COMPLAINTS:

(DD)CORRECTIVE ACTION

ON PREVIOUS REPORTS:

13. RECALL PROCEDURE :

EXPLAIN PROCEDURE ADOPTED FOR

RECALL OF PRODUCTS:

14. QUALITY AUDIT SYSTEM :

(BRIEF RESPONSIBILITIES)