Pipes

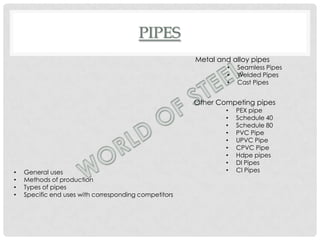

- 1. PIPES Metal and alloy pipes • Seamless Pipes • Welded Pipes • Cast Pipes Other Competing pipes • PEX pipe • Schedule 40 • Schedule 80 • PVC Pipe • UPVC Pipe • CPVC Pipe • Hdpe pipes • DI Pipes • General uses • CI Pipes • Methods of production • Types of pipes • Specific end uses with corresponding competitors

- 2. PIPES AND TUBES • Most often used product produced by the steel industry. • The primary difference between pipe and tubing is how the size is designated. • Pipe is designated by a "Nominal Pipe Size" based upon the ID (inside diameter) • Tubing is designated by the measured OD , ie. outside diameter (and wall thickness sometimes) • NOTE: A 3/4 inch iron pipe has an OD of 1.050 inches, while a 3/4 inch steel tube has an OD of 0.75 inches. • Pipes are used for transportation and tubes for construction purpose.

- 3. RAW MATERIAL FOR PIPES • Black Steel • Carbon Steel • Mild Steel • Alloy Steel • Stainless Steel

- 4. BLACK STEEL PIPE • Black steel pipe is made of steel that has not been galvanized. • It is scaly due to dark-colored iron oxide coating on its surface. • scale formed on the surface of steel pipes when they are heated and forged.( atmospheric oxidation) Black steel pipes are used in : • line pipes in oil and petroleum industries, • water wells and for transporting water • gas and sewage purposes. Black steel pipe gets its appearance because of a black oxide scale formed on the surface of steel pipes when they are forged.

- 5. CARBON STEEL PIPES • Low cost and durable material • Various heavy industries make use of carbon steel pipe. • Poor wear resistance . • Suitable for heat treated parts where high tensile and impact are required.

- 6. CARBON STEEL APPLICATION Major fields of applications: • Connecting rods, Gear shafts, • Chain parts, • Clutches, • Propeller shafts, • Cam shafts, • Spindles • Screws, • Studs, • Pinions, • tappets, • Boring bars.

- 7. MILD STEEL PIPES • Most common material. • Mild steel contains 0.16–0.29% carbon, therefore it is neither brittle nor ductile. • Poor tensile properties as compared to high carbon and alloy steels. • But cost of material and production cost is most justified. • Surface hardness can be increased through carburizing.(if protection from abrasion is crucial). • It rusts easily. • Generally, these pipes are coated with other metals such as copper, to protect from corrosion

- 8. MILD STEEL PIPES • Applications: • Mild Steel pipes and tubing are used for structural purpose and mechanical & general engineering purpose. • It is also used for drinking water supply (chlorination and sodium silicate inhibit corrosion in mild steel pipes.)

- 9. ALLOY STEEL PIPES • Alloy steel contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium. • Pipes made of alloy steel have exceptional performance properties. • Alloy steel pipes are in demand in the domestic, professional or industrial places. In recent years, the demand for alloy steel tubing has been increasing along with the economic growth.

- 10. ALLOY STEEL PIPES • Applications: • These are generally developed for energy-related applications involving oil and gas drilling .

- 11. PRODUCTION Steel pipes are produced by two distinct methods. Raw steel is first cast into a more workable starting form then: • It is made into a pipe by stretching the steel out into a seamless tube or, • The edges are forced together and sealed with a weld (welding technique used is butt weld process)

- 12. SEAMLESS PIPE • Seamless pipes are made by drilling a hole through a billet. • Then it is heated and drawn through dies to take the shape of a pipe. • Since the hollowed center is irregularly shaped, a bullet- shaped piercer point is pushed through the middle of the billet as it is being rolled. • Seamless tubes are typically more light weight, and have thinner walls. They are used for bicycles and transporting liquids. • There is much variation in sizes and application of the seamless pipes( from the size of syringe to huge sewer /gas pipes.)

- 13. WELDED/SEAMED PIPES • Seamed tubes are heavier and more rigid. • The have a better consistency and are generally straighter. • They are used for things such as gas transportation, electrical conduit and plumbing. • Typically, they are used in instances when the pipe is not put under a high degree of stress. • New technologies have greatly improved the butt-weld method of pipe. • Production rate of welded pipes is more , some processes can produce welded seam pipe at the rate of 1,100 feet per minute. • ERW pipes are used in agricultural purposes, drinking Water for housings, in collieries for extraction of Water, Thermal Powers, Transports, Hand pumps for deep boring wells, as a strong protection for cables by Telecom Department, Structural Purposes etc.

- 14. MANUFACTURING Ingot production • An ingot is a material that is cast into a shape suitable for further processing. • Molten steel is poured into large, thick-walled iron molds, where it cools into ingots. • To form flat products such as plates and sheets, or long products such as bars and rods, ingots are shaped between large rollers.

- 15. MANUFACTURING Producing blooms (or slabs) • To produce a bloom, the ingot is passed through a set of 2 or 3 grooved steel rollers that are stacked. Steel is rolled till it achieves the desired shape. During this process, machines called ‘manipulators’ flip the steel so that each side is processed evenly. • Ingots may also be rolled into slabs , there are rollers mounted on the sides to control the width of the slabs. When the steel acquires the desired shape, the uneven ends are cut off and the slabs are cut into shorter pieces.

- 16. MANUFACTURING Processing • · Blooms are converted into billets by passing them through more rolling devices which make them longer and more narrow. The billets are cut by devices known as ‘flying shears’ that race along with the moving billet and cut it. This allows efficient cuts without stopping the manufacturing process. • · Slabs are heated to 1,204° C and then sent through a series of rollers on a hot mill and made into thin narrow strips of steel called skelp.

- 17. MANUFACTURING • This mill can be as long as a half mile. As the slabs pass through the rollers, they become thinner and longer. • In modern mills within three minutes a single slab can be converted from a 15 cm thick piece of steel to a thin steel ribbon that can be 400 meters long. • After stretching, the steel is pickled. This involves running it through a series of tanks that contain sulfuric acid (HCl usually) to clean the thick oxide scale that was formed due to atmospheric oxidation. • Then it is rinsed with water.

- 18. MANUFACTURING • Both skelp and billets are used to make pipes. • Skelp is made into welded pipe. • It is passed through a series of grooved rollers. As it passes by, the rollers cause the edges of the skelp to curl together. This forms an unwelded pipe. • Then welding electrodes seal the two ends of the pipe together. The welded seam is then passed through a high pressure roller which helps create a tight weld. The pipe is then cut to a desired length and stacked for further processing. Welded steel pipe is a continuous process • In modern mills pipes can be made as fast as 1,100 ft (335.3 m) per minute.

- 19. MANUFACTURING • When seamless pipe is needed, square billets are used for production. • They are heated and molded (or forged) to form a cylinder shape, also called a round. • The round is then put in a furnace where it is heated white-hot. The heated round is then rolled with great pressure. • This high pressure rolling causes the billet to stretch out and a hole to form in the center. (centrifugal casting). • Since this hole is irregularly shaped, a bullet shaped piercer point is pushed through the middle of the billet as it is being rolled. • After the piercing stage, the pipe may still be of irregular thickness and shape. To correct this it is passed through another series of rolling mills and lathes.

- 20. STEEL PIPE APPLICATIONS • Domestic water systems • Pipelines transporting gas or liquid over long distances • Scaffolding • Structural steel • As components in mechanical systems such as: • Rollers in conveyor belts • Compactors (E.g.: steam rollers) • Bearing casing • Casing for concrete pilings used in construction projects

- 21. STEEL PIPE APPLICATIONS • High temperature or pressure manufacturing processes • The petroleum industry: • Oil well casing • Oil refinery equipment • Delivery of fluids, either gaseous or liquid, in a process plant from one point to another point in the process • Delivery of bulk solids, in a food or process plant from one point to another point in the process • The construction of high pressure storage vessels (note that large pressure vessels are constructed from plate, not pipe owing to their wall thickness and size).

- 22. GRADING OF STEEL PIPES • Type of pipe used to be designated with a code like API 5L PSL2. • The API range is now ISO E.g.: API 5L Grade B - now ISO L245 where the number indicates yield strength in MPa • ASME SA106 Grade B (Seamless carbon steel pipe for high temperature service) • ASTM A312 (Seamless and welded austenitic stainless steel pipe) • ASTM C76 (Concrete Pipe) • ASTM D3033/3034 (PVC Pipe) • ASTM D2239 (Polyethylene Pipe)

- 23. GRADING OF STEEL PIPES • NPS( Nominal Pip Size ) or NB (Nominal Bore ) is based on inches and DN (Diametre Nominal). So NPS 14 is same as DN 350 • There are then many grades for each standard ASTM Code which determine a minimum yield strength and minimum tensile strength. • The grades include grade 1, grade 2, grade 3, then grade A, grade B, grade C and continue on to grade X and there is minimum and maximum pressure rating each grade.

- 24. GRADING OF STEEL PIPES • Grade A steel pipe has lower tensile and yield strengths than Grade B steel pipe. This is because it has a lower carbon content. Grade A in more ductile and is better for cold bending and close coiling applications. • Grade B steel pipe is better for applications where pressure, structural strength and collapse are factors. It is also easier to machine because of its higher carbon content. • Grade B welds as well as Grade A.

- 25. END PREPERATIONS • Plain end (PE) (small, weld) This is also the default end prep if no end prep is specified. • Threaded end (TE). This would be the choice for small sizes • Bevel end (BE). 3" and larger steel pipe where "butt welding will be used to join pipe to pipe or pipe to fittings.

- 26. A TYPICAL ASTM DESIGNATION ASTM A 582/A582M-95b (2000), A Indicates sequential ferrous number material Year of last revision Indicates Year of that the last re- Usually standard approval written in was SAE written in standard SI units notation

- 27. GRADES USA UK Germany Sweden ASTM A 53 BS3601 DIN 1629 HFS 22 & CDS Grade A SMLS St 35 SIS 1233-05 Electric 22 resistance HFS 27 & CDS welding Grade B SMLS St 45 SIS 1434-05 27 ASTM A 53 BS3601 DIN 1626 Flash butt Grade A ERW ERW 22 Blatt 3 St 34-2 ERW welding Grade B ERW ERW 27 Blatt 3 St 37-2 ERW ASTM A 53 BS3601 DIN 1626 FBW BW 22 Blatt 3 St 34-2 FBW ASTM A 106 BS3602 DIN 17175 2) Grade A HFS 23 St 35-8 SIS 1233-06 Grade B HFS 27 St 45-8 SIS 1435-05

- 28. GRADES Grade C HFS 35 ASTM A 134 BS3601 DIN 1626 EFW Blatt 2 EFW ASTM A 135 BS3601 DIN 1626 Blatt 3 St 34-2 Grade A ERW 22 SIS 1233-06 ERW Blatt 3 St 37-2 Grade B ERW 27 SIS 1434-06 ERW ASTM A 139 BS3601 DIN 1626 Grade A EFW 22 Blatt 2 St 37 Grade B EFW 27 Blatt 2 St 42

- 29. GRADES DIN 1626, Blatt 3 with ASTM A 155 Class 2 BS3602 certification C C45 St 34-2 C50 St 37-2 C55 St 42-2 KC55 EFW 28 St 42-2 2) KC60 St 42-2 2) KC65 EFW 28S St 52-2 KC70 St 52-2 API 5L BS3601 DIN 1629 Grade A SMLS HFS 22 & CDS 22 St 35 SIS 1233-05 Grade B SMLS HFS 27 & CDS 27 St 45 SIS 1434-06 *

- 30. GRADES API 5L BS3601 DIN 1625 Blatt 3 St 34-2 Grade A ERW ERW 22 ERW Blatt 4 St 37-2 Grade B ERW ERW 27 1) ERW BS3601 Double API 5L DIN 1626 welded Grade A EFW ERW 22 Blatt 3 St 34-2 FW Grade B EFW ERW 27 1) Blatt 4 St 37-2 FW API 5L BS3601 DIN 1626 Blatt 3 St 34-2 FBW BW 22 FBW